Latest news and features

Going glamping

What do you do if you want a caravan but drive a Mini? You make one to fit. That’s just what Michael Wolfe of New Plymouth did – turning out a real dinky little teardrop-shaped caravan that matches his 2004 Cooper S and has all the mod cons for a decent holiday.

Michael saw pictures of little campers on the net and decided that was what he wanted – a cross between a caravan and a tent.

“I got some ideas from little caravans online and decided to go a bit more high-tech,” he says.

He built it to have the same lines, wheels and colour as his car and it looks just the part.

“I never really planned it in detail. I sketched it out originally and a lot of the construction I worked out as I went along.”

Cutting threads by hand

From time to time in the home workshop, you may need to make a new threaded hole for a bolt and create the threads on the bolt itself. It’s handy to know how to use the dies that are rotated onto a bolt blank to make these threads, and to know how to use the taps that create the threaded holes. This skill will be especially good for those interested in model engineering, go-karts or light engineering, but who have not been trained in the use of hand tools for making threads.

There are many different thread sizes. These are made to international standards. In all cases, the size of a thread eg, 6mm or ½ inch and so on, is determined by the diameter of the rod or bar on which it may be cut.

Video of the wooden fairground organ built by David Dilks

The 320-pipe fairground organ that David made from scratch is visually and acoustically impressive. The array of beautifully crafted pipes, different shapes and sizes, the accordion-playing monkey, and the drums make quite the show. It’s hard to resist jiggling — but then David and wife Joy, both ballroom dancers, kick up their heels and show their form. Music is a big part of their life.

Electronics: Powerful stuff

Everyone who dabbles with electronics or even automotive stuff will eventually find a bench power supply very handy. When I first started getting into electronics, they were large, expensive beasts, and very much out of the reach of hobbyists. There were a few kitsets provided by some electronic parts suppliers, but these tended to be limited in voltage and current.

If a hobbyist wanted an affordable adjustable supply, they usually had to make it. We even resorted to designing and making our own when I worked for Telecom. Commercial units were available but they didn’t suit our requirements, or budget.

His worship – the shed and vintage cars

The morning we visited this particular sheddie, the bloke was under fire. In The Press, he was being slagged off on the front page. Inside the paper, a swag of writers was pinging him this way and that in letters to the editor. Christchurch is a hotbed of political discontent these days and the buckshot stops with the mayor Garry Moore.

So he’d be in no mood to spend a lovely spring Saturday morning talking to a complete stranger about something as mundane as his not-quite-finished shed? Wrong.

Up the wall

A friend loves gardening and has always wanted a vertical garden or ‘living wall’. She has been pestering me to build one ever since I started doing the welding articles for The Shed. I looked at a few and developed a simple concept that is simply an angle iron frame with a wire lattice.

I measured the wall it was to fit on and arrived at a final size of 1m x 1.6m. I

happened to have that on hand in 3mm angle iron. The vertical garden needs

to be offset to the wall to allow for air circulation and watering. I decided to offset it

by 60mm so that required 100mm feet.

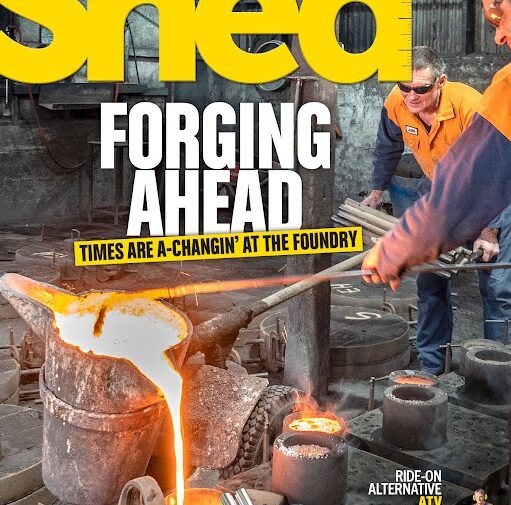

Video of Austins Foundry’s final pour

This is video of a family firm that has provided a good living for at least two generations, building up an impressive skills base while manufacturing essential farm machinery for more than 90 years. The Austin family has run a foundry in Timaru for 93 years. Ken Austin, grandson of the founder, says the business has faced increasing headwinds since the Covid-19 pandemic, so he has tested the winds of change and decided to close down. The Shed visits to celebrate their technical foundry skills, the likes of which we may never see again in New Zealand.

Life in the fast lane

He might describe himself as a larrikin biker, but former world motorcycle racing champion Graeme “Croz” Crosby is really more of a modern Renaissance man.

Put simply, a Renaissance man is defined as a very clever person who is good at many different things. So check the Croz record thus far: Champion motorcycle racer, commercial pilot, successful author, businessman, house builder, skilled motorcycle mechanic, enthusiastic cook, raconteur – the list goes on. He can speak a little Japanese, bake a soufflé or lace up a wire-spoked bike wheel. And even though he turns 62 this year there’s still quite a bit of the larrikin left.

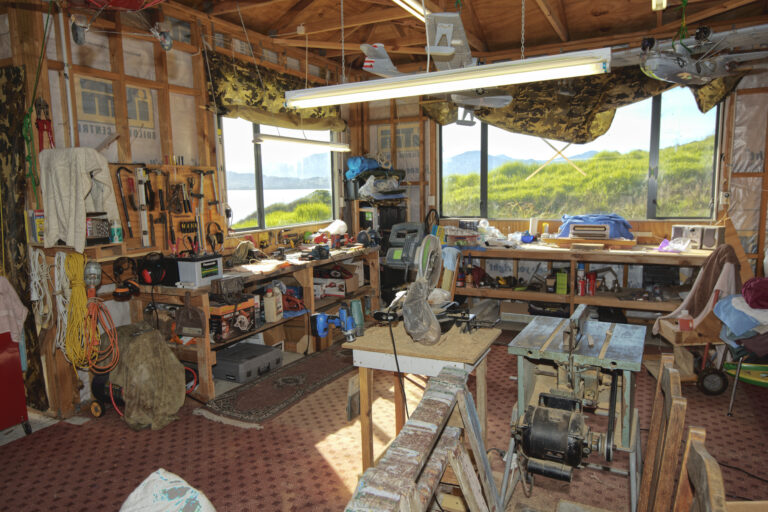

It almost goes without saying that Graeme has a shed. Well, it started out as a hobby shed, somewhere to tinker with old bikes and other motorised toys. In typical Crosby fashion, though, it has become the headquarters for a thriving business restoring and exporting classic Japanese motorcycles. Graeme and his wife Helen bought a 12 acre (4.8 ha) block in the picturesque Matakana countryside an hour north of Auckland more than eight years ago, built a spectacular house, the shed and, across the road, Helen’s The Vivian art gallery.

The Shed magazine October/November issue 111, on sale now

Headwinds in the foundry

The end of an era for Austins of Timaru

Our cover feature this issue is the story of a family firm that has provided a good living for at least two generations, building up an impressive skills base while manufacturing essential farm machinery for more than 90 years. The Austin family has run a foundry in Timaru for 93 years. Ken Austin, grandson of the founder, says the business has faced increasing headwinds since the Covid-19 pandemic, so he has tested the winds of change and decided to close down. The Shed visits to celebrate their technical foundry skills, the likes of which we may never see again in NZ.

Size matters

Back in the carefree/careless days we took a drive up to the Hokianga harbour, mainly for a fish and chip meal at the legendary Omapere pub, and promptly fell in love with the place. It’s New Zealand 50 years ago: clean, uncluttered with houses and people and just plain beautiful on any given day.

The harbour simply sparkles on a sunny day and the dunes on the north head are nothing short of spectacular. The views coming over the ridge from Waimamaku and the Waipoua forest are breath-taking. We still stop and try to take it all in.

Everything moves at a leisurely pace up at the “Hoki”. It is still a hidden gem, but not for long I feel. We have a few celebs up there now and there are more and more serious homes going up, but it still has that laid back feel to it. Opo the dolphin is the only thing that has happened to the area and that was 60 years ago.

Replacing floorboards

Lift the carpet or lino in an old villa to prepare the floor for polishing and you are bound to reveal the gaps or rotten bits in the floorboards.

So how to get them up and insert a tongue-and-groove board into an existing layout? First, work out where the joists are. If you’re lucky, the piece you want to remove will begin and end on a joist, or at least one end will. If not, find the joist nearest to the point you want to cut, usually by tapping the floor.

Often you will see the old nail holes, a good guide to where the centre of the joist might be. Next, scribe a line across the board you want to cut. I use a Tajima knife.

Video of the Ghent Makers Faire

For our electronics features in issues 110 and 111 of The Shed magazine we stepped away from a build project and instead head to a makers’ fair in Europe, this one in Belgium. Young and old were there, keen to display their electronic creations as well as to learn, share and to just enjoy fellow electronic sheddies’ skills.

“Compared to other more famous maker faires events across Europe – Brussels, Rome, Hanover, to mention just the most renowned – the Ghent Maker Faire is considered a minor event. However, it still played host to thousands of visitors and is well worth attending because of its very special character.

As you may have already read in the “News” in The Shed issue 109, the faire hosted the first European power tools racing along the lines of New Zealand and USA competitions. It was organised by the effervescent Henk Ryckaert, who was also the man behind the scenes for the power tools racing on the first day.”

The Auckland Blade Show is back

After last year’s awesome success, The Auckland Blade Show is back again! Come on down to the Guineas Ballroom at the Ellerslie Events centre on 23–24 September to see the finest hunting and kitchen knives, handmade swords and axes, and all the supplies and tools to get into the craft yourself! With more than 50 exhibitors, there will be so much to see!

Tickets are $10 and valid for both days, available on our website and socials. All online ticket purchases go in the draw to win one of several amazing knives!

Follow us on @theaucklandbladeshow on Facebook and Instagram, and see more on https://www.aucklandbladeshow.nz/the-auckland-blade-show

It’s all a matter of scale

They say variety is the spice of life. So it is in the shed. For Taranaki mechanical design engineer Michael Wolfe this means working on projects as diverse as rebuilding a high- powered 1970 American muscle car through to intricate work creating a model of a classic Swiss 1960s train.

Michael re-builds and maintains full-size classic cars and in his spare time model railway construction keeps him busy.

“The skills needed are much the same,” said Michael. “It’s really all a matter of scale.”

His hand-made creation of a replica of an iconic Swiss electric train, the RAe TEE II, is unique – probably the only one in the world.

Panel construction, lathe work, welding, woodworking, and even creating parts with a 3D printer have all been part of the job. In the world of model trains, this is a big one. Each of the six cars that make up the luxury train is about 800mm long.

Michael started off with some plans, photographs of full-size trains, and books, all of which he used to create initial drawings.

Make yourself a decent chef’s knife

Coromandel knife-maker Lloyd Franklin forges his knives from the raw material of coil spring steel rather than cutting or grinding the blades from existing metal shapes. His high-quality knives are sought after by chefs nationwide and by those who appreciate a well-balanced hand-made tool.

Coil spring steel is easily confused with spring steel that we know from a car leaf spring, says Lloyd Franklin. But, he explains, coil spring steel is a high-tech, shock-resisting tool steel from which you can happily make stone-working tools, woodworking chisels or even knives.

The perfect desk job

The desk that is the subject of this article was made for one of my grandsons and is made in a similar style to a bed I made for him several years ago (see the article in The Shed, issue 43, June/July 2012). Like the bed it is made out of beech and finished with Danish oil.

While I have been able to undertake almost all of the processes in my hobby- styled workshop, I want to stress that this desk could be made at home with just a few hand tools. For example, you could ask the timber yard to dress the timber for you; all cutting could be done with a handsaw or a coping saw for the curves; the mortises and tenons could all be done by hand. The process would take longer but you would certainly enhance your skills.

The design process is always interesting for me and, with some initial design concepts in my head, I sit at the drawing board and draw out to scale two or three 2D versions of what I think the final product will look like.

Steely eye

One glance around Allan O’Loughlin’s garden and it’s clear that this is the home of someone with a vivid imagination and the creative skills to bring it to life.

Allan, a fitter-welder and self-taught sculptor, uses the skills learnt in his trade to create works of art in steel. More than 60 of them are scattered around the 9000 square metre property he shares with his partner, Andrea, in Mandeville, 25km north of Christchurch.

Unlike most artists working in the medium, Allan doesn’t construct his sculptures by bolting or welding solid metal shapes together, but relies on the properties of molten steel to mould and fuse his forms.

His initial frameworks are simple structures made out of wire and builders’ reinforcing rods which he curves into shape using heat and a home-built metal former.

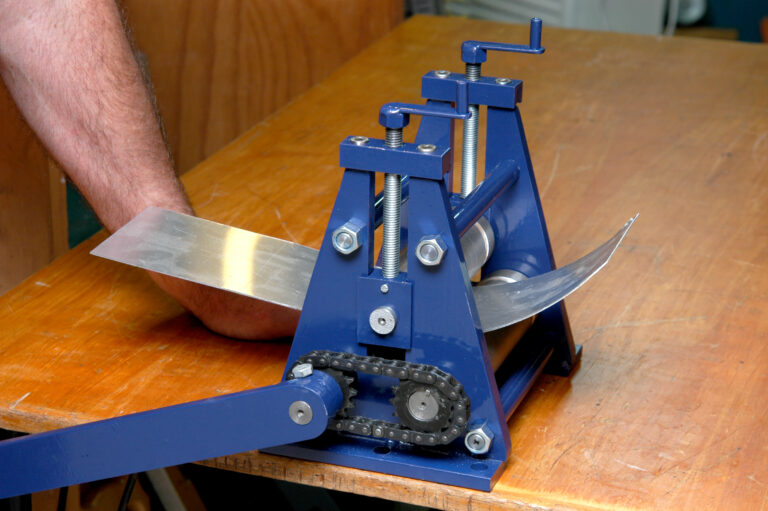

Make a model sheetmetal roller

Isn’t it always the case—you are working away in the shed with the latest project and you need some equipment or tool that you don’t have? I needed to roll some metal for the model project that I am working on and I had recently lost my access to a metal-rolling machine. The best answer was to make my own sheet-metal roller. I quickly realised there were a lot more future projects needing a rolling machine.

Toggle clamps

Toggle Clamps

When it comes to clamping, lever-action toggle clamps offer excellent power from a quick and easy motion and they are simple to install for ready access. Toggle clamps have a multitude of uses in engineering, metal fabrication, and woodworking. Hi-Q Components stocks a wide range of high-quality Turkish-made Kukamet toggle clamps including horizontal and vertical actions, latching or push–pull configurations with different mounting options, and even pneumatic versions.

The Shed magazine August/September issue 110, on sale now

You never know where an interest will take you and for Mark Bedford that interest in fridges has led him to a business where he is the go-to guy for repairing, restoring, modifying and preserving vintage fridges. For our cover story in this issue, we visited Mark in his Auckland workshop where he describes his engineering approach to the preservation of these rare and collectible kitchen essentials.

“Mark’s stand-alone ’60s cinder block workshop sits at the far end of a long driveway skirted by large-scale factories. For this appliance engineer, musician, and general tinkerer, the industrial setting offers the right kind of seclusion.

Mark’s place is equal parts workshop, man cave, and band rehearsal room. His business, hobbies, and work life merge as one. By the roller door, a primer-grey 1980 Bedford CF camper-van conversion sits up on blocks awaiting the installation of a new power-steering system. Next to it, a free-standing 1950s commercial fridge restoration project is in the mock-up stage.”

Firewood sawhorse

I created this little project because I needed to cut firewood easily without someone to assist in holding the wood. Although not my own invention, it is an interpretation of pictures gleaned from the web and adapted to materials that you can buy easily in New Zealand timber yards. The whole project cost me $25 and took about an hour and a half to make. In anybody’s book that is value for money and time well spent.

It is essentially four crosses of timber braced to form a cradle for cutting your firewood.

A king-sized country shed for an ex city boy

When Phil Kindberg decided to escape the Auckland rat race and retire to rural Taranaki with his precious collection of old Studebaker cars, he didn’t dream of the massive shed that was waiting for him.

Two years ago he made the shift south and purchased the 100-year-old Riverdale dairy factory, not far west of Hawera.

The big factory, which in its heyday specialised in cheese production, already had a bit of a past with motor vehicles, having been a panel beating shop for a while and also once housing a huge collection of old Citroen cars.

Now on display in the factory are Phil’s seven Studebakers from 1947 to 1962, a 1958 Packard, a mate’s collection of 40 motorbikes, including some classics and home-made bikes, and other weird and wonderful machines.

Build your own smoothing plane

Here is an outline for making a small steel and brass smoothing plane which looks similar in style and size to the common Stanley or Record No 3 size. There the similarities end.

The main differences are the blade is 5mm thick, it has a screw blade-adjuster but no back iron or chip-breaker. The screw-type cap is bronze and massive. The sole is 8mm thick and dovetailed to the 6mm thick brass sides. The knob is a refined version of the Stanley but the rear handle is a more radical departure. There is no frog. The blade is solidly bedded on a steel bridging piece which connects the sides to enhance rigidity and houses the swivelling adjuster mechanism, allowing for lateral adjustment of the blade.

Jet Bike

Paul Jury likes going fast. He enjoys the world of speed so much he’s attached a micro jet engine to a push bike. Paul’s bike has been cranked up to 120kph and he thinks it can go as fast as 150kph.

The New Plymouth man, who runs Floorcoat Taranaki, said he and his mates like speed and a bit of danger. They’re into activities such as drift triking, wake boarding, kite surfing, snowboarding, and skydiving.

Checking out a few YouTube clips they decided to up the ante and use jet power.

“The jet motor was originally attached to planks of wood and when we first cranked it up, it tried to take off in the workshop, showering anyone behind it with gravel,” says Paul.

The next step to check out its capabilities was attaching it to a go-kart but Paul said the kart was a bit heavy to realise the maximum potential of the jet.

Attaching it to the bike worked a treat.

Chips and dip, anyone?

I have used a piece of swamp kauri from Kaitaia for this project. The wood may well be 45,000 years old although pieces of swamp kauri have been carbon dated from 1000 to 50-60,000 years old from different parts of northern New Zealand. The time-scale of this wood is mind-boggling. How do we get this wood? You keep your ear to ground for news about logs and stumps that emerge, then we have to get off our backsides and do something about it. Swamp kauri, and occasionally other timber dug from old swamps have not rotted because they are preserved in anaerobic conditions. Kauri is the most common “swamp” wood because it is the slowest wood to deteriorate when above the ground before the land area became swamp.

For woodturners, kauri is a soft wood. Puriri, pohutukawa, black maire are hard woods, although botanists use the terms “hardwood” and “softwood” in a way that is related to the type of tree and not the hardness of the wood.

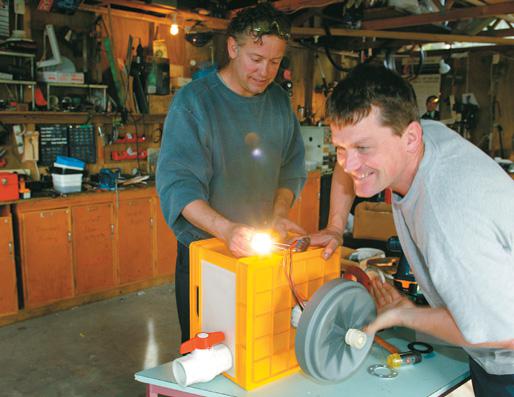

Build a hydro power plant

Ever thought of creating your own electricity? It’s a challenge a number of New Zealanders aspire to these days, as rising power prices and possible insecurity of supply bring out the Kiwi leanings towards independence and DIY.

And how to do it? A small stream, a broken washing machine, a shed and you’re away. Well almost.

Video of power tool racing in Belgium

In late April, the city of Gent, Belgium, hosted the annual Gent Maker Fair (https://www.makerfairegent.be/nieuws), an exhibition dedicated to all the crazy inventions of makers in Belgium.

On the fair’s opening night of 30 April, the Belgian Power Tool Drag Racing Championship entertained the visitors in a one-off event.

Popular in many countries around the world, this is a spectacular race of electric ‘vehicles’ powered by 220VAC and built with one or two power tools such as drills, chainsaws, and any other kind of electric-powered hand tool. The only rule is that it must be a tool that can be used by hand.

In the next issue of The Shed, issue 110, I will give more detail on the challenge. If it sounds like your kind of fun, there is the option to participate in the 2024 event.

Raising the bar

I have wanted to make an elevating bar stool for some time. They are a relatively simple design – four legs attached to a nut through which an acme thread runs, raising and lowering the seat.

However, attaching the legs to the nut is problematic. The nut is usually a fairly large piece of steel, in this case it’s 38mm diameter, and even with the hole and threads cut it still has a wall thickness of nearly 10mm. The legs on the other hand have a wall thickness of only 2mm. That size differential makes using MIG welding difficult. It can be done of course but it isn’t quite as straightforward as usual.

I felt it was ideally suited to TIG welding and as I hadn’t tried TIG before I thought this might be a good opportunity to get some experience.

The Shed June/July 2023 issue 109, on sale now

Our cover story this issue is on one man’s paradise. Gary Norton’s shed is crammed with vehicles in various stages of restoration. Classic Fords sit alongside a bevy of trucks and a unique build of a mini Kenworth. Jason Burgess visits a passionate Westie’s mega-sized shed.

“As shed sizes go, Gary Norton’s is a megastore. It needs to be, because, despite the square footage, space is at a premium, crammed as it is with “a bit of everything” and no end of enterprises in various states of progress.

There is a saying about the more you have, the more you are occupied. Luckily, Gary and wife Raewyn are as industrious as they come. They run their rural property as close to organic as possible. Even when they both worked full time away from their land, they still managed to raise 22 different breeds of chickens, rear calves, fatten sheep, and breed goats.”

Warning: boiling point!

I own an American classic car and it comes with the usual 1960s instrumentation—speedo, fuel gauge but only warning lights for oil, alternator, and water temperature. The alternator light comes on when you turn on the ignition, but the water temperature light is designed to come on only when the water temperature reaches 120-125 °C which is usually too late.

To fix that, I have devised this program powered by an Arduino micro-controller that will operate the temperature light when the engine powers up and light it up again to warn the driver as the temperature approaches 100 °C. It uses a readily available sender that will fit most vehicles.

Arduino software for wipers and temp gauge projects

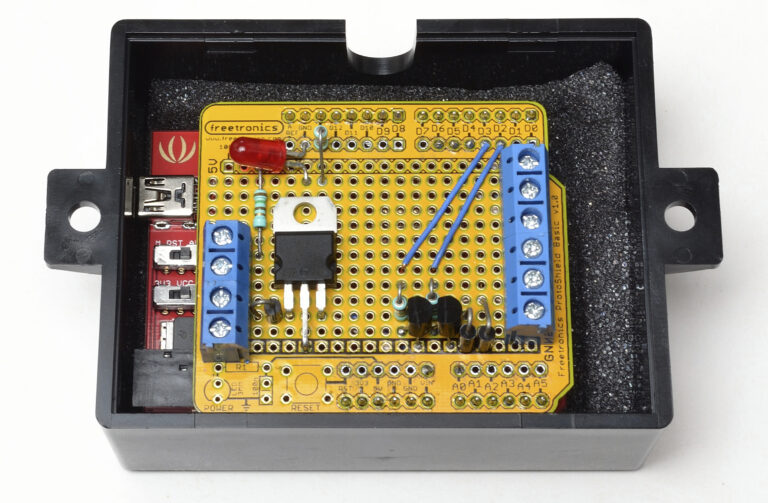

Controller

I chose to use a shield (add-on board) to house all the parts for this project that allows the use of any standard Arduino and settled on a Seeeduino V3.0 and a Freetronics prototype shield as an inexpensive solution.

I used the controller and shield to for the previous variable wiper speed project for the car (“Wipe that classic windscreen,” Shed, Apr/May 2012). This second part uses the same controller and shield to do both tasks. The reader can either make one or both. The shield construction includes the extra parts (two resistors, one transistor, and one diode) and uses the “Start” button to do the “Normal” calibration.

Here are the two sketches (software) in these The Shed website’s two posts.

one combining water temperature light and variable wiper functions into one controller; and

one that just does the water temperature light.

Wipe, wipe that classic windscreen

I own an American classic car and there are a few mod cons that are missing. I’ve added central locking because crawling over seats was a pain, but I thought the Arduino could add a few features that aren’t available in the shops. This is the first of two parts which uses the same piece of Arduino hardware to do two different tasks—run variable-speed wipers and a temperature gauge. Each can be used on their own as it makes no difference to the software

Out of the box

The modern incarnation of the chest is the blanket box which sometimes doubles as a seat so it needs to be strong enough to support weight as well. This project is no more than a box with a lid and base. Dowels are the primary jointing method throughout and the top and base use a floating panel within a frame. There is also a small sliding drawer which is also dowelled together.

Hot water tune up

Research tells us that around a third of all energy used in the average New Zealand home goes in heating water. Another third goes in room heating.

In our home the rooms are mainly heated free from the sun so the water-heating fraction of the total energy use is a lot more than a third. Most water-heating systems aren’t well tuned. Improving their efficiency usually brings significant cost savings, a welcome relief in the current economic climate. Often it’s easy and costs little to do.

Fire dance

A yellow sign indicates an historic site ahead and soon an old corrugated shed with “Blacksmith 1889” emblazoned on its side comes into view. Not so unusual, but a driver might do a double-take when he spots the glow of the ancient forge and hears the ring of metal on metal as he passes. While the smithy in Teddington, on the road from Lyttelton to Port Levy on Banks Peninsula, is a relic from a bygone age, the man at work is a real live 21st-century blacksmith.

Top gears

Contrary to what the poets say, its gears, not love, that make the world go round. The magic of an exquisitely constructed timepiece with its myriad whirring cogs is an eternal delight. Horology has always fascinated me, and it has long been an ambition of mine to build the mother of all clocks, an orrery. Named for the 4th Earl of Orrery who commissioned George Graham to make the first modern device in 1704, they mark not just the passing of the hours, but the exact movements of the planets as they beat out Kepler’s laws.

The Shed April/May 2023 issue 108, on sale now

Our cover story this April/May 2023 issue 108 proves that it’s never too late to take up a new interest.

Whanganui sheddie Peter Loidl is a home renovator from way back and when he met some members of The Whanganui Woodturner’s Club at an exhibition, they encouraged him to join their club and have a go at woodturning. The results of Peter’s efforts on the lathe are really quite outstanding.

“In Peter Loidl’s living room, a 1:2 scaled-down Model T Ford made from various timbers does duty as a liquor cabinet. The bonnet and tank lift up to reveal a stash of spirit and wine bottles that have accumulated for years — they are mostly unopened, Peter tells us. He has wired up the headlights, back lights, and dashboard. He has also installed concealed colour-changing lighting where the bottles sit. There’s no drink-drive message intended; the car bar serves a functional purpose and is also an unusual decorative feature.”

Rescue those versatile stepper motors

Magnetism is wonderful stuff.

As a way of moving things it has no peer. It has no friction, excessive heat or other unwanted effects, and is easily harnessed in the shed in the guise of stepper motors. These versatile devices have an astonishing range of rotational speeds, from zero to tens of thousands of rpm.

Thanks to the precision of digital control, they can accelerate, decelerate, turn a specific number of times or even minute fractions of a single rotation – all repeatedly and reliably.

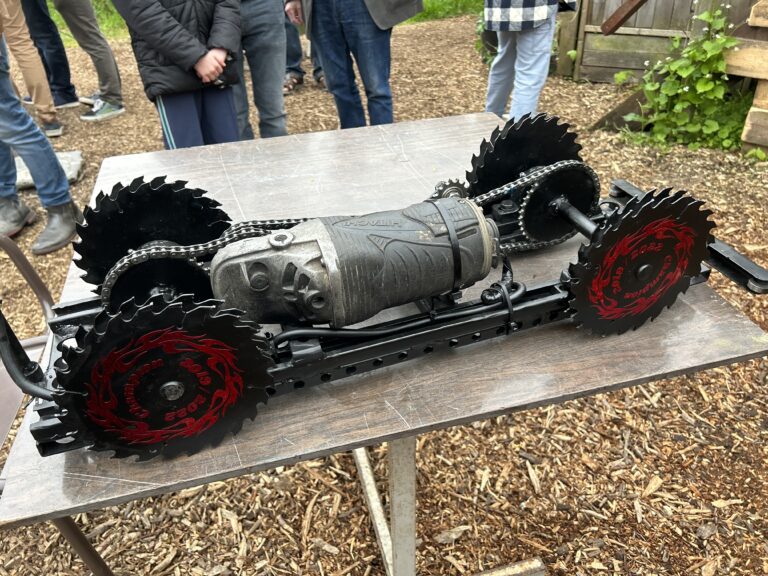

This offroader project is a beaut

Over the last couple of years, my son Kurt and I have built a few basic go-karts which not only gave him a taste of very basic engineering, but also allowed us to pile up valuable hours of quality time working together in the shed. This new project had a bit of a twist to it as, this time, my son was the chief designer and engineer and I was relegated to labourer. Like all the previous projects, he let me fund it.