The fridge magnate

Keeping classic fridges alive

You never know where an interest will take you and for Mark Bedford that interest in fridges has led him to a business where he is the go-to guy for repairing, restoring, modifying and preserving vintage fridges. For our cover story in this issue, we visited Mark in his Auckland workshop where he describes his engineering approach to the preservation of these rare and collectible kitchen essentials.

“Mark’s stand-alone ’60s cinder block workshop sits at the far end of a long driveway skirted by large-scale factories. For this appliance engineer, musician, and general tinkerer, the industrial setting offers the right kind of seclusion.

Mark’s place is equal parts workshop, man cave, and band rehearsal room. His business, hobbies, and work life merge as one. By the roller door, a primer-grey 1980 Bedford CF camper-van conversion sits up on blocks awaiting the installation of a new power-steering system. Next to it, a free-standing 1950s commercial fridge restoration project is in the mock-up stage.”

Camper-van conversion

Making your own camper-van

Many of us have the strong desire to own a camper van and in the true sheddie spirit, why buy a ready made when you can make your own. In our ‘From the archives’ feature this issue Bert Toomey shows us with good planning, how a very ordinary van becomes a camper-van, pop top and all.

“Converting an ordinary van to a camper van is a project I have been talking about for some time. As a retired technical teacher, I felt I had the necessary skills and when a Kia Pregio van in excellent condition became available I decided to take the plunge.

The van is a 2.7-litre diesel, manual, with 26,000km on the clock and a cargo space of 2.8 metres by 1.58 metres. My plan was to fit the space with two beds, one each side. These can be expanded to become a double covering the full width with a mattress on a board bridging the gap between the two side benches. Fitments include a cupboard with the sink on top and tanks for clean water and grey water below.”

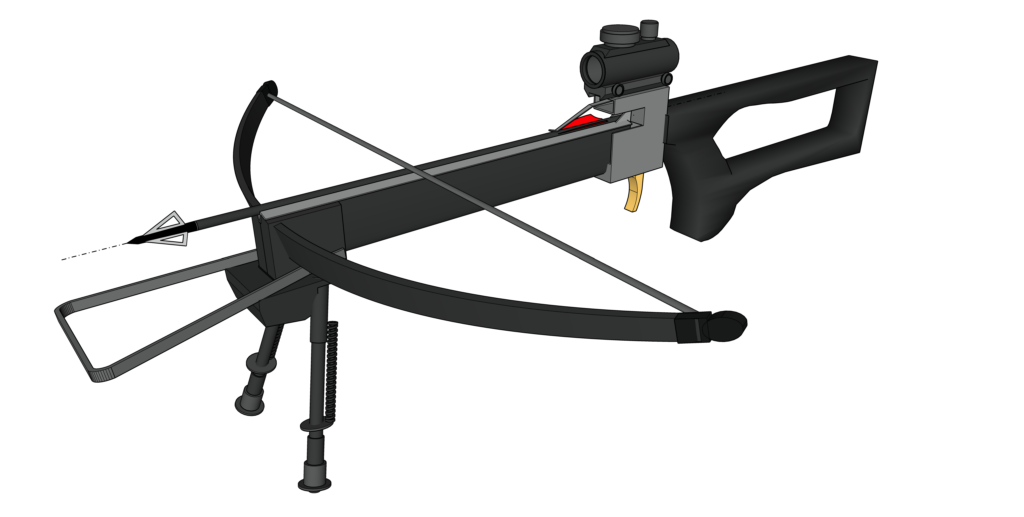

Make a crossbow – Part 1

Crossbows – very old, very cool, very lethal

Nigel Young has been fascinated by crossbows since he was a young boy and rather than buy one off the shelf he saw it as an opportunity to have a crack at making his own. There’s a lot to learn and be aware of, safety rules and regs just for starters, and we join him as he heads off on his journey in part one of this three part series.

“Crossbows have always fascinated me. As a weapon, they transformed warfare from around 650bce through to the beginnings of gunpowder-based firearms; as a project they have all sorts of interesting challenges.

Just because they fascinate me, however, doesn’t mean I know anything about them, but I’m a designer, so – in the words of Jeremy Clarkson – how hard can it be?

This article will take us from determining the nature and extent of my ignorance in this subject, through some sketches I’ve drawn up to help me understand it, and finally to a foam board mock-up of what I would like to achieve.”

Software test

Alibre 101 – Part 7

We are getting close to the end of this tutorial series on how to use this Alibre design software and by now your skill level will be right up there. In this part 7 of our 10 part series, Bob Hulme describes how to show Assemblies. Our tutorial for this issue is how to make a dimpling die.

“In this, part 7 of our Alibre Atom 3D series, we will look at how assemblies can be shown. There are two methods for making assemblies in this program. The first is called ‘bottom up’, whereby the separate parts that come together to make an assembled product are already designed. The second is, not surprisingly, called ‘top down’. This allows parts to be designed as the assembly is created, and parts can be configured to suit the other component parts as they are fitted together. This does not mean that parts cannot be altered when the bottom up method is used. In fact, it’s not difficult at all to change each part when you find a problem – such as parts not actually fitting together. However, it does mean that you have to open the Individual Part file to make the changes and then update the assembly. We will use bottom up assembly for the purposes of simplicity.”

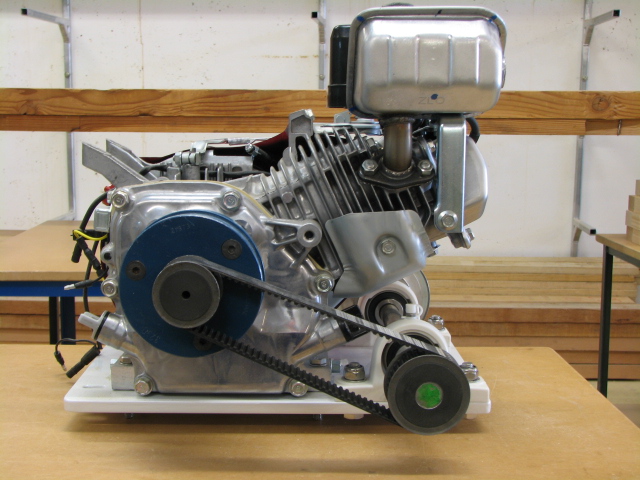

Small engine installation

Simple and cheap engine installation

In the previous issue of The Shed magazine, a reader asked if we could go into some detail for him on choosing and installing a small engine to do a specific task and of course, we were delighted to do just that.

We headed back to explore further the small engine installation undertaken by Neville Watkinson into his build of a Milford 20 yacht in The Shed issue 107. Was it going to be a cheap and efficient use of a petrol engine or not?

“When designing the Milford 20, (see “Kiwi ingenuity”, The Shed issue 107, March–April 2023) I realised that some form of auxiliary propulsion would be desirable. Many slipways in New Zealand are located within the confines of a marina, and these places typically don’t allow sailing within their area.

Initially I thought about oars; however, to be effective they would need to be quite long, and that created a stowage issue. The next obvious solution was an outboard motor. I think these represent one of the best solutions for a small boat if it doesn’t lend itself to oars; a relatively cheap, simple, self-contained power unit that is also portable. Modern outboards are fairly refined and quiet, qualities that I value in a power unit, and can be very fuel efficient, depending on the hull shape.”

Building the ultimate shed – part three

The final touches

Des Bromilow completes the build of his ultimate shed, a build where he has left absolutely nothing to chance. Every aspect of the perfect workshop has been installed here, including storage and extensive future proofing. Des finishes off the build this issue with his guidelines for the perfect shed – safety, security, and ease of operation.

“The mezzanines in my shed build could present a real danger for people accessing them. The height of the mezzanine level exceeds 2m – all too regularly, fatalities occur in falls less than that within the building industry and other industries. All countries have standards for handrails, and I applied the relevant one for my jurisdiction. The handrails are required to withstand a lateral force of 30kg, and meet a minimum height. The handrails I built and fitted to the mezzanines meet those standards. During the design, it was decided to place only a single access point for each mezzanine. This meant that each opening would need a gate (or door) and all other parts of the mezzanines could be barricaded properly. The handrails were welded up and fitted to the mezzanines, and painted in the requisite traditional high-visibility colour.”

Off the grid

Meccano magicians

Murray left his off the grid workshop for this issue’s column when he learned of a nearby Meccano club meeting and exhibition. He had no choice, he had to visit and was so glad he did, there were some breathtaking examples of this classic building toy on display

“Making’ is something I contemplate a lot.

At one end of the spectrum there are folk who build things – from models to the full-size article – from scratch. At the other, folk who buy a kit – a plastic battleship, for example – where 99 per cent of the ‘making’ has been already done. I’ve learned to appreciate the skills involved at both ends, and long ago came to the conclusion that it is all legitimate if it floats your boat – so to speak. However, somewhere in the middle is a format all on its own: premade material out of which items can be assembled, disassembled, and reassembled. Leggo/Duplo/Technics, K’Nex, Polydron, old-school wooden building sets – they all fit into that category, but the standout is Meccano.”

Electronics

Ghent Maker Faire – Part 1

For our electronics feature this issue, we step away from a build project and instead head to a makers’ fair in Europe, this one in Belgium. Young and old were there, keen to display their electronic creations as well as to learn, share and to just enjoy fellow electronic sheddies’ skills.

“Compared to other more famous maker faires events across Europe – Brussels, Rome, Hanover, to mention just the most renowned – the Ghent Maker Faire is considered a minor event. However, it still played host to thousands of visitors and is well worth attending because of its very special character.

As you may have already read in the “News” in The Shed issue 109, the faire hosted the first European power tools racing along the lines of New Zealand and USA competitions. It was organised by the effervescent Henk Ryckaert, who was also the man behind the scenes for the power tools racing on the first day.”

Northbrook Museum

This is a story about a man and his museum

Richard Spark ran his family’s dairy farm in partnership with his brothers John and Bob from when he left school until he retired 42 years later. Richard started collecting items of interest from an early age and now that interest has turned into a huge multi-shed museum complex along with a conference centre, funeral centre, cafe and chapel on the outskirts of Rangiora.

“Because Richard kept on collecting, it was only five years before a new, similar, building was needed. Richard wanted his collections to be seen and the museum increasingly attracted visitors, who paid a small admission fee to view the relentlessly growing number of artefacts of our social history on display. These visitors often wanted a cup of tea or coffee and a snack. Richard and his wife Dawn used a small office in the building to brew tea and butter the scones that Dawn baked for the patrons. A third voluminous attached space was completed in 2000.”

Building a wattle garden shelter

Ancient methods still have their place in modern buildings

Bob Van Putten is another sheddie that lives off the grid and he aims to create what he needs using what’s to hand and what’s affordable. It also needs to suit his environment. In this article bOb describes how he builds a simple garden shelter using nearby sourced timbers and ancient preservation and building methods.

“The old shed had been a rabbit hutch at one time and I hadn’t bothered to tear it down once the rabbits were gone. It then filled up with stuff, as sheds do. The replacement was going in the same spot so first I had to empty and tear down the old one. I got to sorting through the junk and got rid of most of it. The only real reason I need that shed is to house a generator to power tools in my nearby shop. Nevertheless, I figured I’d make the new shed 8 feet x 11 feet (approx. 2.4m x 3.3m), which was somewhat bigger than the old one, with a higher roof – they always fill up.

Up here in the northern USA, lumber prices have truly skyrocketed recently. We’ve still got plenty of trees, and loggers to chop ’em down, so it isn’t scarcity driving up prices. Whatever the reason is, prices have tripled or more in the past year. That’s a good reason to find something else to build with.”

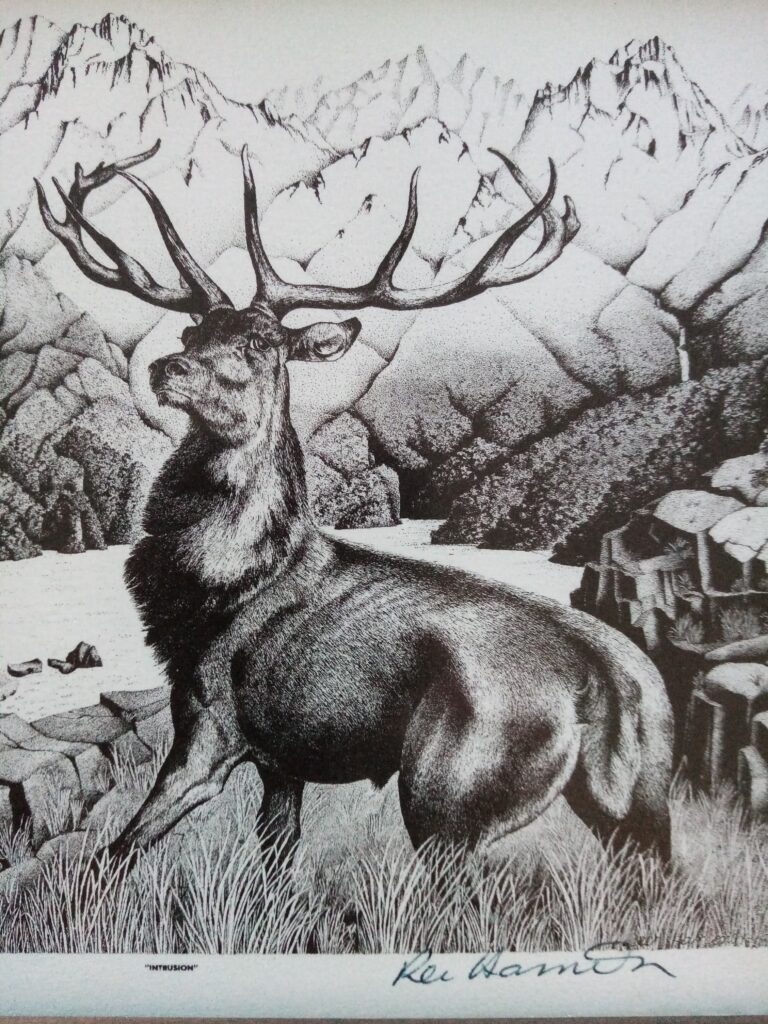

The Shed shrink

A thing of beauty is not only a joy forever; it can also inspire us and contribute to our mental well-being.

Our mental well being coach, Mark Seek, sees the huge benefits in being creative and what a joy it is to be so but also to appreciate those around us that are incredibly creatively talented.

“Over the years, there have been many artists I’ve had a penchant for, most of whom have prompted me to look at life and appreciate how others view it. My appreciation for art provides a new energy for my own ‘ongoing projects’. This allows me to move in a positive direction and overcome – dare I say the word! – procrastination.

Early in my teens I was given a book of drawings by Rei Hamon. His work left an impression on me; even to this day, I find it incredibly moving and somehow spiritual. I was lucky enough to purchase a signed print of the magnificent stag work that the artist famously sold for $20,000.”

Buggyrobot in Oamaru

Martin Horspool – junkyard genius

Through the years of having successful exhibitions and even getting commissions from overseas, working all weekend on his art, Martin kept the day job as a printer until finally, in August last year, he decided he had had enough. He quit his job, left Auckland and headed south to start a new life doing what he loves the most, creating pieces from others discarded metal and more. Now he is doing and creating all and every day the things that really matter to him.

“It is generally regarded as wisdom to leave well enough alone, but Martin Horspool is not having a bar of that.

Here is a man who considers nothing worth having, using, or wearing until he has either found a novel use for it or transformed it utterly. Nothing is spared – not his Honda 50 step-through, not the lamp over his desk, not the desk itself, not even his own hair, a white mane that stands straight up like bristles on a yard broom. Everything around Martin bears his original and always stylish stamp.”

Back o’The Shed

Getting off the ground

The Shed magazine founder, Jude Woodside, moved properties some time back and has been planning his new shed build for what seems like years. Well, it’s now fully underway and he could not be happier about it. However, there are issues.. of course.

“At first I assumed that the erection would be easy; what could possibly go wrong? The portals didn’t look too intimidating on the ground, but at five metres in the air the real scale became apparent. I hired a scissor lift, hoping that we could use it to raise the portal frames, to manhandle them into position, and then to attach the purlins for stability. After the first day, when we experienced all the ways that plan could go wrong and spent the day erecting just two of the five portals, we regrouped and, with the benefit of hindsight, had the rest up in about half the time.”