Latest news and features

Best of The Shed2 on sale now across Australia

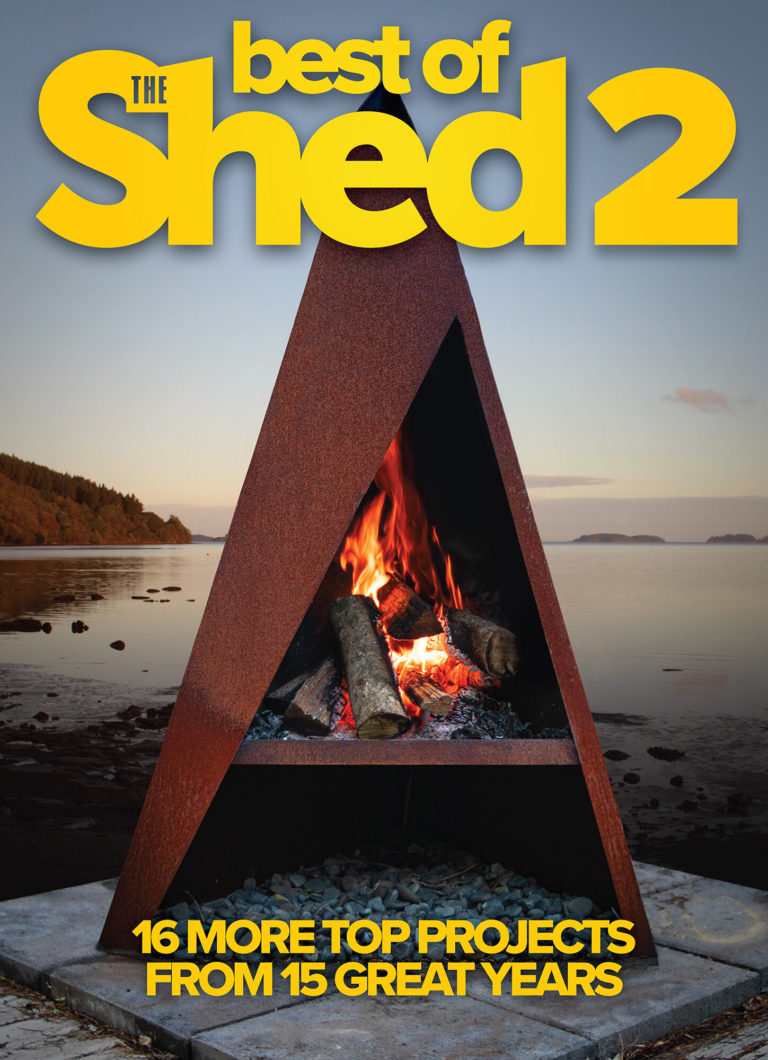

Whatever your workshop passion, from woodworking to welding, from electronics to outdoor projects, there are some great ideas here. If you are a newbie, give them a go — you have to start somewhere in your journey to be a creative sheddie. We have 16 more great projects in this second edition of Best of The Shed. All have clear instructions that demonstrate the build process and include diagrams and parts lists.

Sheddies on both sides of the Tasman have been inspired by the projects and informative features we run in the magazine, and this is a selection of some of our most popular articles from the first 15 years of The Shed.

Best of The Shed2 on sale now

Whatever your workshop passion, from woodworking to welding, from electronics to outdoor projects, there are some great ideas here. If you are a newbie, give them a go — you have to start somewhere in your journey to be a creative sheddie. We have 16 more great projects in this second edition of Best of The Shed. All have clear instructions that demonstrate the build process and include diagrams and parts lists.

Sheddies on both sides of the Tasman have been inspired by the projects and informative features we run in the magazine, and this is a selection of some of our most popular articles from the first 15 years of The Shed.

Installing sliding doors

French doors give a house much readier indoor-outdoor flow, especially when they open onto a deck. The old villa being renovated for this project had existing French doors leading from the back of the house to the outside.

However, the owner wanted a wider, more user-friendly opening and the answer was a bigger set of doors. The doors in this project are unusual

The Shed March/April 2021 Issue 95, on sale now

Making Damascus steel is a true skill and the patterned finish really adds style to any knife. These knives are rightly famous for the keen edge they can be sharpened to and the length of time they retain that edge.

But how do you get those distinctive patterns the same each time and do that consistently? Well, we have found a knife maker who can do just that. Matt James has been making Damascus steel since the late 1990s and now does so from his well-equipped and spacious workshop.

Sawing with shush

If you haven’t heard these Tusk Silent Timber blades in operation you can’t fully appreciate what a difference they make. They are not silent but they are significantly quieter, and probably never squeal. These ultra-thin, deep-cutting, premium-quality saw blades are made especially for use on electric or cordless circular saws. They feature a patented sound

How to save crumbling wood

Earl’s Wood Hardener penetrates into soft and rotted wood fibres, restoring them to near original strength. It makes repairs possible to even the most fragile wood, ready for full restoration. Forget digging out rot. Earl’s Wood Hardener will penetrate wood fibres, and once dry, you can patch and paint, if necessary.

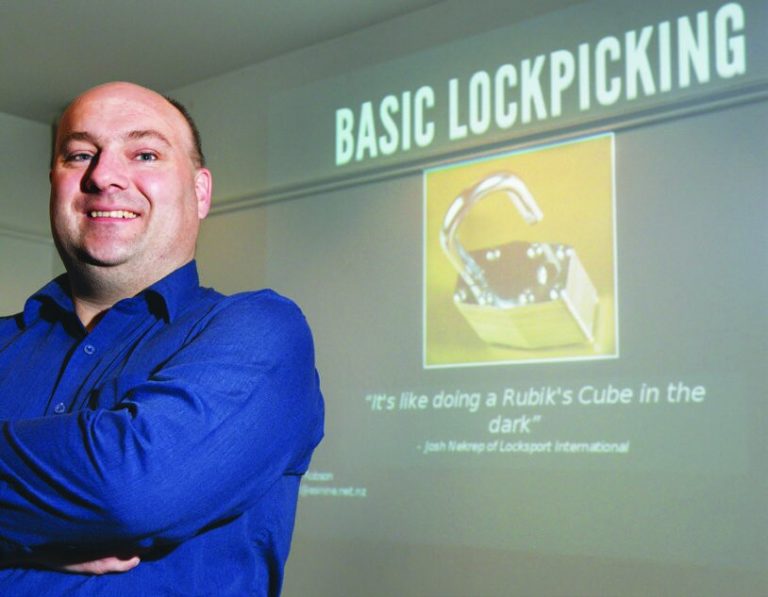

Channelling Houdini

In a sash-windowed meeting room in the upper reaches of the historic Thistle Inn in Wellington, an unusual band of people is preparing for their monthly meeting. Master lockpicker and meeting organiser Derek Robson, aka D.Roc, is assembling an array of locks; dozens of them—mortise locks, pin tumbler locks, tubular locks, various padlocks, combination locks, wafer locks, even a selection of handcuffs, to challenge tonight’s group.

The bike dude

Gary still lives in the house where he was raised in rural Taranaki and he spends a lot of time repairing bikes to give to kids so that they can have the freedom he enjoyed in his childhood.

Gary is known locally as “The Bike Dude” and he’s been doing this for a while. There are second and third generations of kids out there riding bikes Gary has renewed.

The Shed Issue 94, the January/February edition, is now on sale across Australia

The magazine is now on sale at your favourite newsagent and subscribers’ copies are with Australia Post so will be with customers in the coming days.

Here is where to find your nearest local The Shed stockist and check out the fully-illustrated rundown of what’s in this issue.

To purchase a copy of this issue or subscribe in Australia, from only NZ$49, head to our online shop.

A matter of time

I purchased all the brass sheet and rounds required, plus a main-spring, brass bolts, and screws of the various sizes needed.

Now where to start on the clock?

I carefully read and followed the order and instructions of the book. If the instructions are not adhered to, many anxious moments and frustrations will follow.

Vertigo CNC turns dreams into reality

Vertigo CNC routers are proudly New Zealand–designed-and-developed, and they’re locally manufactured too, in Christchurch. The mid-size desktop Vertigo MX2-N, which has a working area of 1200 x 600 x 120mm, delivers accuracy, utilizing lead screws and stepper motor control, at an affordable price.

It offers flexibility in part size and material choice, working with plywood, wood, plastics, aluminium, and other non-ferrous metals, and there’s a Facebook community of more than 600 users for this desktop router. The Vertigo MX2-N CNC has an RRP of $6995, incl. GST. or $47.00 per week on finance. For more information, visit vertigocnc.com, or see Vertigo’s YouTube channel, or visit Facebook.com/vertigocnc.

This is the nail

Merry Christmas to all our Shed magazine readers and website fans. The Shed is taking a few weeks’ break from posting content but we are hard at it prepping the next issue of the magazine whilst we grab a bit of summer R&R.

Have a great summer holiday and enjoy that extra time now available to you for your special projects. However, before you get stuck into any home maintenance projects, have a quick read of this poem by one of our Shed favourite writers, Rod Kane. You may just decide to have a beer instead.

This is the nail

..that sparked all my fears

Of maintenance imperative, painting, repairs

The portico leaked, just a rusty old nail

But it wasn’t just one, the whole roof was a fail

So up there I goes and a…

Metal life saver

Autosol Rust Ex is a powerful, industrial-strength corrosion and stain remover that is quick and easy to use — it’s as simple as wiping on and rubbing off for standout results. It quickly removes rust, tarnishing, discolouration, oxidation, and even bluing, and will give metal surfaces a new lease of life. See hobeca.co.nz for more information.

Fractul (or Lichtenberg) wood burners are not safe, do not build or use

WorkSafe NZ has contacted The Shed and advised us of two recent deaths of New Zealanders using a Lichtenberg wood burner. They have advised us that these electrical devices are not safe to use and are dangerous.

Do not build or use one of these machines under any circumstances as they are unsafe and can cause fatal injuries.

See this information on the Worksafe website https://www.worksafe.govt.nz/about-us/news-and-media/fractal-burning/

Rain, rain come again

Imagine filling a 300-litre tank with rainwater in an hour* …

Twist is a compact rainwater diverter that makes the most of the free rainwater collected on your roof by connecting your downpipe to a small tank, giving you free water for gardening, cleaning, topping up aquariums, ponds or pools, or as an emergency supply.

Cutting edge

Make light work of cutting most materials with the two-piece Tusk Retractable and Folding Utility Knife Set. Lightweight and durable, make tool-free blade changes at the press of a button and the foldable knife can be operated with one hand.

Ultimate outdoor entertaining

Create the ultimate outdoor entertaining area, uniquely tailored to your needs, with a Gasmate Avenir 6 or 4 gas barbecue and modules. Made from 304 commercial grade stainless steel, the Avenir range looks great and is built to last, with high-output stainless steel burners, a rear ceramic rotisserie burner, and a side burner catering to budding chefs.

Burning bright

Making a brazier is one of those things that I am sure every sheddie has at the back of their minds to create one day. It’s just that, as we know, “one day” takes its time arriving.

I have to admit that I am no exception to that rule. Even when the component parts presented themselves to me it took a while before I found the time to put into the project. Six truck brake drums that had outlived their useful life were the starting point, donated by the owner of a fleet who only asked that one of the braziers be made for him.

A night at the speedway

The allusion to knights and jousting is apt. Like knights in armour, the drivers especially of the sprint cars have very restricted vision. They can peer through the grille in front and can see a bit to the left but their right-hand vision is blocked by a wing and within the confines of the cockpit—with helmet and neck brace in place—they have very little opportunity to turn their heads. To make things worse, other cars are flinging up dust and mud that also helps to clog their vision.

Hold your grip

Injection moulding is ideal for manufacturing grips with unique contours and patterns that are difficult or impossible to achieve using other grip-processing technologies.

GripWorks’ very popular line of ‘Hunt Wilde’ injection-moulded FPVC grips come in a variety of styles, with local distributor Hi-Q Components stocking plain straight, ribbed nubbed, contoured bump, straight ribbed, tapered flanged, flanged rib-finned, and honey comb options. Perfect for the likes of outdoor power equipment, lawn and garden tools, sporting goods, bicycles, maintenance equipment, and much more, the GripWorks Hunt Wilde range is designed to fit standard bar sizes and diameters, including: ½-inch, ³/₄-inch, ⁷/₈-inch, 1-inch, 1¹/₄-inch.

See the Hi-Q Components website to order online or for more information, email [email protected] or call 0800 800 293.

The Shed January/February 2021 Issue 94, on sale now

There’s a real Triumph in the issue of The Shed and a twin-engined one at that as well as the bonus of our annual The Shed 2021 wall calendar.

Our cover story this issue is about a central South Island marine engineer sheddie who really is living the dream. A love of classic cars and motorbikes has seen this marine engineer buy a working garage to store and restore his own collection as well as operate it as an everyday mechanical repair garage for local customers.

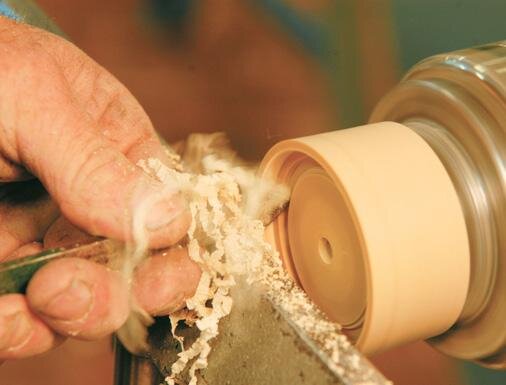

A satisfying lidded box

The size and shape of the lidded box is limited only by the size of wood you have, and your imagination. Keep in mind that the size of the lid must please the design of the box as a whole. I usually strive to make the size of the lid approximately one-third of the total box size.

The Shed Issue 93 now on sale in Australia

Well, it took a bit longer to arrive than usual but at last, the November/December 2020 Issue 93 of The Shed is on sale across Australia from today, Thursday 19 November.

The COVID 19 pandemic has played havoc with international freight shipping so its later than usual arriving in Sydney for distribution around the country. Australian subscribers will start receiving their copies from this week as well.

Make your own mortar water feature

As far as Do-It-Yourself art goes, I believe this is probably the best value for money, extremely satisfying, not to mention therapeutic, and it can last for years outside or can be passed down through the generations. I now enjoy doing this for its own sake, too. When you come home tired from work, it can be very relaxing to pour a mould of mortar in a box, or using one you prepared previously, to just start shaping and sculpting.

Polish query ‘Autosolved’

If you haven’t heard of Autosol, you can thank us later.

This revolutionary, ammonia-free product is the go-to cleaner and polish for uncoated aluminium surfaces. It leaves a clean sheen without scratching or hazing. The distributors say users describe it as “a product that does everything the advertising says it does”, “my go-to polish for aluminium”, and “perfect for alloy wheel rejuvenation”. It is available in a 75ml tube with screw caps from automotive, engineering, and hardware stores across New Zealand.

Sharpen up your blades

When honing a cutting edge on a steel blade, you are progressively over three or four stages reducing the size of the scratches on the two faces which meet up to make the sharp point.

The much-vaunted “mirror” edge simply refers to the stage where we cannot easily see the scratches with the naked eye and hence it looks smooth and shiny. This process, therefore, requires several sharpening stones with finer and finer surfaces (325 grit, then 1200 grit, then 6000 grit).

How to make jandals

First, we need a pattern for the sole. For yourself, stand on a suitable-sized piece of paper and have someone draw around your foot. It’s best to do so while you stand erect to give the maximum silhouette of your foot. The person marking must hold the pen perpendicular and be careful not to slant the pen under the arch of the foot or the heel.

Electric bikes – taking care of business

Let’s face it e-bikes are everywhere and they are here to stay. If the thought of extra complications and potential breakdowns are putting you off buying one then you’re not alone. Would you like an e-bike that you can build and maintain yourself?

Something that goes better than most, is easy to service and diagnose with readily available parts and plenty of support is becoming a priority for a lot of people looking for an e-bike that won’t end up as landfill in a few years’ time.

An elegant table with cabriole legs

Walnut is a great wood to work with and machines and finishes superbly. Timber like this deserves to be used in something special and this piece although it looks deceptively tricky is actually relatively straightforward and something that will be of use for generations. The elegant curves of a cabriole leg add an organic feel to a table.

The Shed November/December 2020 Issue 93, is on sale now

We showcase the metal-shaping and coachbuilding skills of Rod Tempero Motor Body Builders Ltd from Oamaru in The Shed Issue No. 93. The company’s world-famous and internationally sought-after car-building talents make it one of this country’s finest coachbuilders. We head to the mainland to meet Rod and his team and do our best to dig out as many metal-shaping and car-building secrets as we can.

A dead accurate optical punch

An optical punch consists of a brass body with two holes through it, one for use, the other for storage, because there are two rods. One rod is the punch, the other a vertical magnifying glass made of a plastic rod. You look down the viewing rod at a dot marked on its base. You then move the whole apparatus around until you can see the point where you want to put a punch mark. Holding the brass body, you remove the plastic rod and drop the steel punch back into the same hole, then hit it. Result: a perfect, vertically punched mark, precisely on the spot.

Folding wooden sawhorse plans from The Shed Issue 93

Here is an easy download for the plans to construct a foldable wooden sawhorse from The Shed Issue 93.

Pleasant Point Railway photo gallery

We visited and wrote about the impressive Pleasant Point Railway & Historical Society in South Canterbury, in The Shed September/October 2020 Issue 92.

Sadly, we just couldn’t squeeze in all the great photos we shot for the article into the magazine. As you will now see, these unpublished photographs are just too good to leave sitting on our hard drive so we felt we just had to share them with readers.

Enjoy.

Shed 92 on sale across Australia today

For all our Australian readers the wait is over to grab the latest issue of the magazine. The September/October, Issue 92, hits the shops all across the country from today 17 September.

Spotless shine

Polishing metal isn’t a task for which you want to be ill-equipped, especially when you’re chasing that perfect shiny finish! That is why Autosol has been the most trusted name since forever. The new Autosol 3in1 for Stainless Steel is specially developed to clean, protect, and leave a shiny streak-free finish on stainless steel surfaces — with anti-fingerprint effect.

Is it a beer keg? No, it’s a hangi

It’s not every day that you come across a blindingly brilliant and deceptively simple use for a piece of gear that you just knew would come in handy one day.

When sheddie Stan Scott showed me his prototype portable beer keg hangi, I knew it was something that the world needed right now… like world peace.

Installing a sash window

Old villas don’t necessarily have all the windows desirable for modern living.

In the project here, the homeowner wanted to install another window into an outside wall. The most effective method was to buy a window that was made by a joinery firm to match the existing window and create the hole in the wall to match.

Video of the weird and wonderful world of Andrew Hall

A visit to Andrew Hall’s shed — a single garage in suburban Henderson, West Auckland — is a portal into another dimension. In this realm, a sense of humour is essential.

For the past two decades, Andrew has been working full time at turning society’s cast-offs into three-dimensional cartoon gargoyles, aliens, monsters, and effigies of mirth.

2020 Father’s Day gifts for Dad

Keep Dad comfortable, entertained, and productive with these great products. We’re counting down to Father’s Day 2020 with these awesome deals!