Latest news and features

Build an Almost Ready to Fly Warhawk

Then there is the relatively new kid on the block: the ARF (Almost Ready to Fly) model.

These come all packaged up in a huge box, beautifully built and packed, with all the hardware. But you do need to assemble them which can take up to a week. It isn’t quite ‘instant plane’ but it does provide some building satisfaction and a sense of achievement, albeit a rather shallow one, a bit like a healthy walk down to the bakery to buy a pie or taking Viagra.

To the supplied kit, you need to add various glues, an engine and electrical components (servos, relays, wires) to operate elevator, rudder, ailerons, throttle, flaps, undercarriage etc. The engine these days could be glow plug, 4-stroke or 2-stroke, electric or petrol.

This part of the hobby is now huge and the range and quality of products is astounding. ARF aircraft kits are readily available from many hobby shops and certainly online from within New Zealand and from lands far away.

Mac N Sea

Piopio in the heart of the King Country – a landlocked area with a village population of about 400 – is the last place you’d expect to find a boat builder. Boat builder Max Laver, however, is well settled there and business is thriving.

Boat repairs, restoration, and making small craft by hand is the speciality of Max’s business, where he works with fibreglass and timber, and specialises in custom-built dinghies.

“We focus on how well we can make a dinghy, not how cheaply,” he says.

Max is a marine surveyor as well as a boat builder.

He spent two years in Lowestoft in England learning City and Guild-level wooden boat building, and finished his time doing two more years learning in New Brunswick, Canada.

In 2009, after many years boat building, Max decided to study marine surveying and the two qualifications work hand in hand.

“I didn’t excel at school as a kid, but I loved to build,” he says.

Industrial style at home

My daughter was looking for a large lamp for her husband’s birthday and struggled to find something with the modern industrial-type of look that she had in mind. She asked me if I could make something around her thinking. She particularly wanted a large tripod base with an adjustable lamp on the top.

We searched around for a suitable lamp for the top and found an adjustable lamp on a spindle base at Lighting Direct on sale for $89.95. We would have preferred a matt black finish but we felt the chrome model would work very well.

Preserving the past – by the tonne

What do you do when your passion for collecting means you are accumulating objects that can be measured by the tonne?

One answer is to buy a big building and open it up to the public – Mike’s Museum in Eltham displays the extraordinary results of Mike Coil’s collection mania.

Two upper stories and a huge basement of an historic building in the small Taranaki town are bulging with the strangest things. A big collection of antique chainsaws, World War II objects, including an anti-aircraft searchlight and US submarine generator engine, steam boilers of all sizes – you name it – Mike’s collected it.

There’s also a great collection of historic tools and objects from New Zealand’s past.

Mike began collecting when he was a young fella. One of a family of 12, he was raised on Taranaki farms and he recalls when aged eight his father coming home from a stint at sea with a handful of coins.

Video of From Rust to Rrrroaarrr Part Four

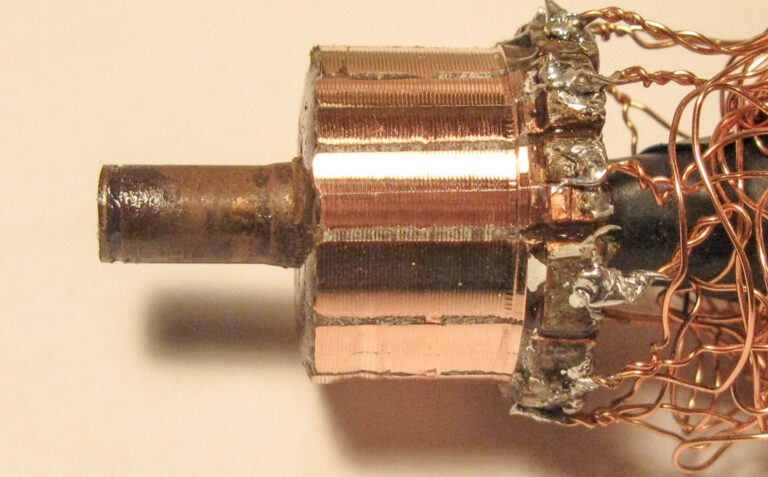

In the first article, I wrote about nickel welding repairs to a broken cast iron engine cooling fin, magneto check, head repair, valve work and nickel plating the push rod cover tubes.

The second article was mainly about how I developed nickel and copper plating, with a little bit about kickstarter repair using nickel plate on a worn shaft and grinding teeth.

The third article, the start of frame painting, engine, clutch and gearbox assembly and installation, with magneto timing.

For this fourth episode, I had planned to write about how I rebuilt the electrical system, reupholstered the seat and renovated the fuel tank. There has been progress on each of these three things but little in the way of meeting targets.

A model life

If the phrase “small but perfectly formed” can be legitimately applied to a shed, then Bruce Geange’s Palmerston North workshop certainly fits the bill. In a space of about 2 by 5 metres he creates Lilliputian machines that mimic their full-sized cousins in everything but size. An exquisitely detailed D8 1940 bulldozer is 40 cm long and completely hand-built. Bruce says it took about 900 hours to complete and is completely functional.

Born in Taumarunui in 1935, the eldest of four boys, Bruce was raised on various farms in the Manawatu area, which may explain his predilection for tractor models. A life-long love of modelling started at the age of 11 when he received a No 1 Meccano set for Christmas. As finances permitted he began collecting Meccano, building up to a No 9 set after he began working.

Steampunk toy: Back to the future

Having been bitten by the steampunk toy bug recently I couldn’t resist trying once again to bring the theme to bear on another model. I have always admired the elegant lines of the clinker-built Viking longboats, their savage, war-like image on storm-tossed seas, and the whole mythology of the Viking era. I decided to see if I could combine that vision and steampunk to produce a modern take on the old boats.

As with my other steampunk toys and models, I chose a central element around which to base this one. The ultra-smooth, mirror-like, hard-drive disks I had used as hub caps in a previous steampunk toy are especially well suited to replicate (with a modern twist) the Viking shields that adorned the gunwales of their longboats.

The Shed magazine June/July 2025 issue 121 on sale now

With the genealogy of the five generations of South Island engineers in the family, Ross Hayes thinks nothing of rebuilding Land Rovers for fun, family and farm.

Ross Hayes was 17 when he bought his first Land Rover. It was road-legal, but that was about it. It turned out that it was cosmetically covering up a huge amount of rust, so it wasn’t going to make the long haul.

Ross bunches his lips. “I got a bit disheartened and decided that if I couldn’t trust anybody to sell me a good one, I’d build myself one.”

He bought a 1954 short wheelbase Series 1 Land Rover in December ’96, just after he turned 18. “I paid six hundred bucks to a guy out of Naseby called Owen Rawcliffe, who’s since passed. I brought it back to Oamaru through the Danseys Pass and set to pulling it to bits.”

He bought workshop and parts manuals from the UK and a set of Whitworth sockets and Whitworth spanners and got stuck in.

The Mistress, as he came to call this ‘54 Series 1, spent five years, three months in the workshop – 6000 hours – while he pulled it to bits and rebuilt it.

His idea was to start with a chassis, and everything that went onto the chassis was either rebuilt or brand new. It was hard to get parts back then in the 1990s.

A man of many sheds

Sitting on the edge of a little paddock in the river mouth settlement of Kakanui, ten minutes drive south of Oamaru, is a ramshackle shed where Lindsay Murray creates things of rustic beauty.

The shed has a long history. It was built in 1875 as the house and shop of a nurseryman, George Packwood, who came from Scotland to plant and tend trees around the mill manager’s house in Kakanui.

When Lindsay, an artisan wood worker and sometimes blacksmith took it over in 1993 the back wall had fallen off, half the roof was collapsing and the floors were rotted through in the living quarters. As far as Lindsay was concerned, it was perfect.

It had the remnants of the original dwelling: a kitchen with no running water but with a working coal range, and two other rooms which have served, over the years, as sleeping quarters and a sitting-cum-dining room. This is where Lindsay stays overnight when working on a major project. It also serves as temporary accommodation for visiting artisans and is currently home to Rolands Selis, a highly skilled leather worker.

VERSATILE SHED OF THE YEAR COMPETITION!

Do you have New Zealand’s most interesting shed?

Whether it’s the cleanest, most cluttered, an epic man cave, or simply one-of-a-kind, we want to see it!

We love them all, and now it’s your chance to show off your shed and win!

Think your shed has what it takes?

Enter today and claim the crown!

HOW IT WORKS:

We’ll select the Top 5 sheds. The finalists will be showcased on Facebook, and the public will vote – most likes & comments wins!

WHAT YOU WIN:

A $500 Prezzy Card. A feature spot on the cover of The Shed Magazine, 2026 Calendar

HOW TO ENTER:

Send a high-res JPG image of your shed

Email your entry to: [email protected]

Entries close: July 31st

Facebook voting runs:

August 1st – 10th. The winner will be notified by email.

Lights galore

If you are interested in adapting and using discarded bits and bobs to make something useful, then building lights, table lamps, and the like, offers an endless source of relatively inexpensive projects to amuse you. What’s more, they make unique gifts and nice conversation starters for visitors. Lamps are also a good way of supporting a decorating theme. Whether you are into an Art Deco, Arts and Crafts, modern or industrial look, it is nice to enhance your chosen theme by constructing a light from an object that is reminiscent of it.

Of course you are dealing with 240-volt electricity, which is potentially lethal, so it is essential that you use common sense and particular care when wiring up lights (see the safe wiring tip box). The advent of 12-volt downlights powered by small transformers has also made the construction of lights much safer. Lights can now be wired in such a way that the 240-volt transformer is remotely located or secured and independently earthed. There is no electrocution risk posed by the 12-volt wiring in the rest of the light.

Child’s play

When you are a carpenter by trade with an interest in cars and still young at heart, making wooden toys has to be the perfect retirement occupation—although many of Alan Gray’s “toys” are not the sort of playthings you would put in the hands of small children. His meticulously crafted vintage vehicles, fashioned mostly from native timbers, mahogany and macrocarpa, can take around 60 hours to make and are more collectors’ pieces.

To keep the real kids happy, he has a more robust range mostly made from pinus radiata— diggers, trucks, pull-along hippos and the like.

Alan, 71, and his wife, Lesley, have been living in Cromwell for the past six years. Originally from Dunedin, Alan trained as a carpenter but turned his hand to fishing after moving to Stewart Island. He then spent the best part of three decades skippering boats for the Department of Conservation.

The Ayrburn Classic announces dates for 2026

Save the date: Friday 20 – Sunday 22 February 2026

That’s right. The Ayrburn Classic returns next February for what promises to be another world-class celebration, scheduled slightly earlier on the calendar to bask in Central Otago’s long golden evenings and late-summer glow. This festival will once again transform Ayrburn into a playground for car enthusiasts, food lovers, and seekers of high-end hospitality alike.

The 2025 edition set an incredibly high benchmark, and is fast becoming one of the leading reasons to visit Queenstown – amongst New Zealanders and international travellers alike. With over 250 classic and contemporary luxury vehicles on display – collectively worth more than $250 million – the festival was a visual and visceral feast for attendees.

Futuristic fabrications

A sci-fi artist working from a backyard shed in Central Otago is turning stuff no one wants into things that are sought after across the globe.

Sean Boyd uses anything that takes his fancy, from light fittings and plumbing parts to typewriters and old vacuum cleaners, to make futuristic fabrications which include ray guns, life-sized robots, jetpacks and other cosmic curiosities.

“The satisfaction is in finding parts, imagining outcomes and working out how they can fit together,” says Sean, who gets most of his raw materials from the local recycling centre, Central Otago WasteBusters. “I fill the back of the car for about $35. I think I’ve got more waste here than the waste station,” he says, looking round at the piles of paraphernalia in his humble garage in Clyde.

Hand tool grand slam

It splits wood and rock, it severs roots, it levers…it slams. The Slammer may be a literally ground-breaking tool to work with, but the manually operated device is a rare creature in the thriving high-tech landscape of new DIY tools.

Developed by TJ Irvin, a globe-trotting American who settled by Lake Hawea more than a decade ago and handcrafted by one of the oldest engineering firms in the country, Templeton & Sons, the Slammer is an unusual piece of kit any manual worker needing a bit of extra grunt should consider trying.

The 9 kg, two-piece Slammer developed by Irvin uses the impact of a solid, high-tensile steel rod rammed down a length of pipe by the operator. This provides the momentum to ram the attached blade into—and through—the sort of material most people hire a jackhammer to deal with. Other attachments turn it into a fence-hole rammer and a compacter for foundation work. As TJ describes it, the slammer/rammer multipurpose tool is a combination of a crowbar, axe, spade, mattock and sledgehammer all in one. Made in New Zealand.

Valve radios: Retro Radio magic

The family gathering around the wireless to listen to the Friday evening programme may be a thing of the distant past but the beauty of those old valve-driven radios lives on in the dedicated work of Retro Radios.

Based in Dannevirke, Alister Ramsay works from an assortment of sheds, a garage and a container lovingly restoring old valve radios and radiograms. In a workshop redolent of the glory days of the 1940s to the 1960s, with nostalgic posters for Life magazine and a smattering of old cameras – another hobby is collecting old cameras – Alister works to a background of smooth jazz issuing from a variety of beautifully restored valve radios producing warm-toned music to set the mood.

Video of From Rust to rrroarrr – part three

In my first two articles about the rebuild of a bitser 1952-ish AJS 500 motorcycle, I outlined how I welded a broken cast-iron cooling fin on the motor, checked the magneto ignition and got the head repaired.

I also described what I had learnt about nickel plating (using surplus nickel welding rods and then nickel tape) so that I could make a relatively cheap substitution for chromium, eg on pushrod cover tubes and bolt heads.

Nickel plating was also used to build up a worn kick-starter shaft as a part approach to stopping the kick-start from jamming; I also ground back a couple of teeth on the starter quadrant gear.

My bitser’s gearbox

The gearbox is a Burman CP type, used on many English bikes, with a code G45 L47 stamped on it.

The L in the code refers to the month of assembly, so November.

47 is the year: 1947. So this would have gone into a bike probably in 1948. (My claim to be rebuilding a 1952 AJS looks shakier.)

My shed: Going bush in town

Many guys like to retreat to a space they have created and feel comfortable in. For some, it’s a shed to tinker in and build things, for others it’s some sort of man cave where they can socialise with their mates.

Gary Were of Stratford, in Taranaki, has gone a step further. The 71-year-old year semi-retired builder and deer hunter has re-created a replica of his favourite bush hut under his urban house.

For 30 years Gary has been deer hunting in the Urewera ranges in the centre of the North Island. It’s an isolated place, where the boys get flown in by Heliseka Helicopter and spend a week each year hunting sika and sometimes red deer.

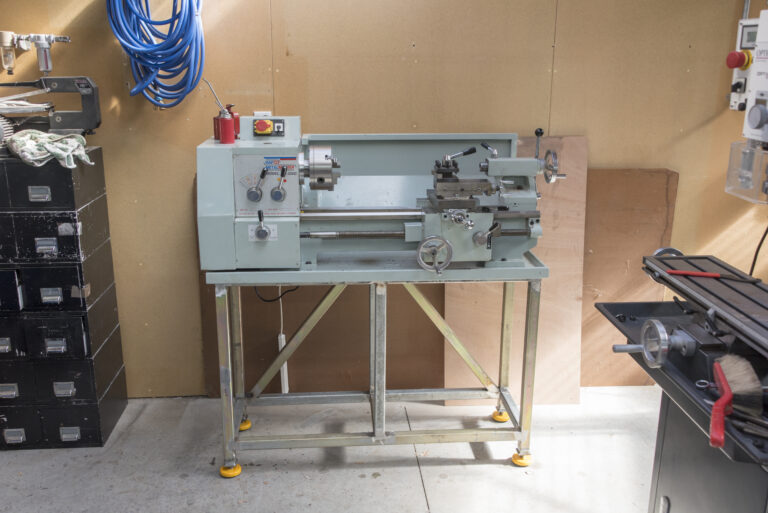

Welding: Standing to attention – lathe bench build part 2

I ordered some drawer slides of the appropriate length (350mm) and worked out the width of the slides and thus the width of the drawers. The drawer slides are rated at 45kgs. I couldn’t be sure what weight I would be likely to load but this should suffice. I elected to run with eight drawers and make the second opening in the frame a cabinet to house larger components like the four-jaw chuck. After some fiddling I settled on two drawers each of 75mmx70mmx60mm, and 50mm high, separated by 10mm.

I bought three sheets of cold rolled steel 1mm thick. This is within the limits of the panbrake and I had hoped the material would be stiff enough given that the drawer had to span over 500mm width. I broke the material down into half sheets to make it easier to handle.

The Shed magazine April/May 2025 issue 120 on sale now

On the road again – new life for old caravans

The allure of a classic caravan can be strong, and many of these gems are being lovingly restored – in fact, Beach Hop even has a prize for the best retro caravan.

In this issue, we showcase three very different caravan restorations—one by a man who owns a company that has been building caravans commercially since the 1950s and is now a household name in caravans and Motorhomes.

The second is a lovingly restored 10-footer that started off a real basket case, and the third, well, friends christened it a turd emoji when they saw the project bought by Marty and Zoe.

Their caravan was destined for their annual pilgrimage to Beach Hop, where thousands gather to show off their super-primped or lovingly restored classic vehicles and caravans

Man who gives a toss

The incentive for the project came from Dave’s sons, Josh and Andrew. The boys were jumping their bikes and Josh (13) came up with the ultimate idea—throwing their bikes with a trebuchet which they had seen in action on computer games. The boys started with a small trebuchet using stones but it didn’t throw them far so dad got into the act. Dave checked out machines on the internet that were even throwing cars. The world record is a 630-metre throw. He was impressed and thought he would give it a go. He had some Lawsoniana trees he intended to drop so thought now was the time. He finds the Lawson trees were straight and the wood is very flexible.

Welding: Standing to attention

I moved recently and in the haste to pack I loaded my lathe complete with its stand. The stand, which is really just a couple of sheet-metal cabinets, didn’t really survive the move all that well and it was bent out of shape.

That didn’t really bother me since I have wanted to make a decent stand for the lathe since I got it, and include some drawers for tooling and other bits and pieces. Now that the lathe is in its permanent home I have my chance. This is just a small lathe but it weighs 250kg nonetheless.

I wanted to make something sturdy and solid that would serve to support the lathe without sagging and eliminate any vibrations.

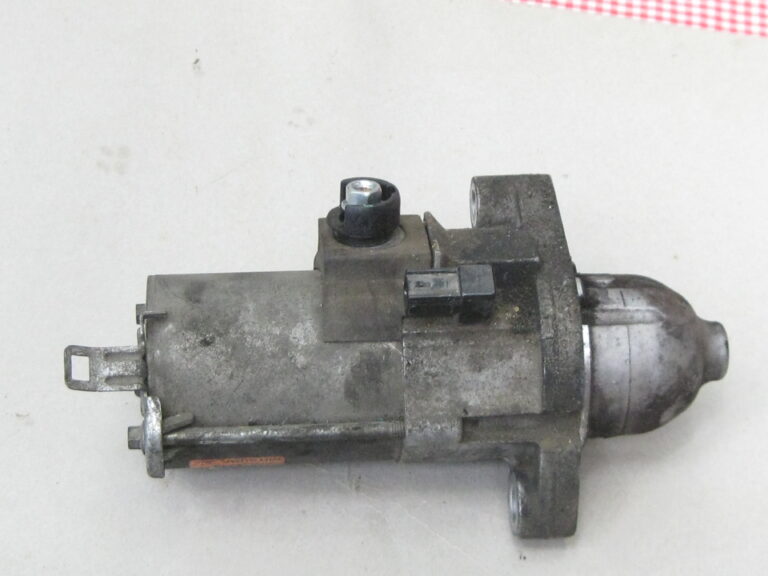

This could be good news for sheddies – but we must be quick!

Our parliament is currently considering a member’s Bill, drawn by ballot, called the ‘Right to Repair’ Bill. It’s due to go a Select Committee for consideration, and we can make submissions i.e. say what we think of it, before 3 April this year. It’s important because it will make spare parts and information for doing repairs far more readily available and this should slow the rate at which appliances, toys and so on, get sent to landfill.

The great Greek gear train

Many years ago in a history of technology, I read a passing mention of a strange artefact, a piece of mechanical gearing, that was in the Athens National Archaeological Museum. I didn’t know then, but getting to see this would become an obsession in my life.

The artefact was recovered in 1900 from an ancient Greek galley. This ocean-floor wreck was accidentally discovered by sponge fishermen sheltering from a storm by the tiny island of Antikythera. One of the artefacts later taken from the ship was a corroded block of copper which, after it was cleaned, revealed the vestiges of a complex gear train. This has come to be known as the Antikythera Mechanism.

The Shed King is going to Bonneville, can you help get him there?

“My name is Dave Alexander, and I am on a mission to set a land speed record of over 420 kph at the iconic Bonneville Salt Flats.

With decades of experience in motorsport dating back to the 1970s, I have had the honour of competing at Bonneville before, where we achieved three records in just one week with my home-built car from New Zealand.

My latest creation is an impressive 7-metre ‘Lakester’, engineered specifically for land-speed racing and powered by a turbocharged Nissan RB30 engine. As a self-employed engineer, fabricator, and welder, I took on the challenge of building this vehicle in my shed with support from a small team of skilled friends.

In February 2025, we successfully completed the build and ran the car on a hub dynamometer, ensuring all systems were calibrated and functions tested. This marked a crucial milestone in our journey. Now, we face the next challenge: packing the car and transporting it across the globe to compete in ‘Bonneville Speedweek’ 2025.

Soldering tips part 2: Getting the job done

We touched on some simple de-soldering methods in part one of this two-part series.

Just like other workshop tools, there is more than one way to achieve it and with less damage and frustration.

De-soldering involves removing the solder from the joint to either release the component or repair the solder joint. The aim is to do this with minimal damage to either part, but since you can generally replace the component, protecting the PCB is paramount.

SMT (Surface Mount Technology) is a whole other subject, and because of the design and density of the components, different tools are required.

De-solder or rework stations consist of a box controlling a heated tip and a vacuum pump. There are many manufacturers, but I’m only going to discuss some of the ones I’ve had experience with.

While the control box may have shrunk, there is a limit to reducing the handset. The handset consists of a tube to collect the solder and filters to absorb the flux residue. The tips are hollow and reach right through into the collection tube.

A movable bench with fold-away legs

Before I down-sized my workshop, I had a garage workshop area and plenty of room to have the traditional type of sawhorses or saw stools. Now I have just half of a double-garage which means the stools have to be stored out the back in all weathers.

I was looking at a sheet of 16 mm ply that was 1200 mm square and could see it would make two stools that would fold away flat and could be stored inside. They wouldn’t take up space standing permanently in the garage/workshop and they would need very little room folded away.

Waka building – Tradition goes hi-tech

Architect, designer, sailor. Add lateral thinker, enthusiast and passionate Kiwi to the mix and you have the CV of a Christchurch man who has made it his mission to put Maori waka back on the water by marrying traditional knowledge with today’s technology.

Quentin Roake’s goal is to find a way to build waka in numbers, recreating the appearance and characteristics of traditional craft in a modern version that is portable, durable, and economical to manufacture.

“The big question is, how do you translate the traditional form of canoe into modern materials? You can’t cut down a big totara tree every time you want to make a canoe,” he says.

Quentin’s quest for a solution involved consultation with tohunga waka (canoe experts), including Hoturoa Barclay-Kerr and Sir Hekenukumaingaiwi (Hector) Busby, and led to Nga Waka Tangata kaupapa, a collaborative project to develop contemporary forms of waka.

Soldering on Part One

Everyone knows that at some stage you need to blame your tools (after the other excuses have run out), and like most things you can pay a little money or a lot, and sometimes there is little difference in the result … or so it would seem.

The purpose of this article is not to separate you from your hard-earned cash, but to share a few tricks and provide some information to make an informed choice when buying equipment.

Everyone knows that the best soldering iron is some large lump of material that you throw into the fire until it is red hot and then apply to the job and hope that some of the exploding material fuses the bits together.

That might work for joining two bits of metal together but it is not going to work for electronics.

Soldering electronics is not only mechanical bonding, but also making an electrically conductive joint. The solder used has a particular temperature range and too hot will ‘cook’ the joint and make it porous, while too cold means it sticks to one or other part but doesn’t bond.

Video of from Rust to Rrroarrr Part two

From Rust to Rrroarrr Part Two

As featured in The Shed magazine, February/March 2025 issue 119

A six-part magazine series on the restoration of a 1952 AJS Motorbike

PART TWO – Metal plating:

The secrets of successful nickel plating

In part one of this restoration series, Peter described how he started rebuilding, as cheaply as possible, an old bitser AJS 500 motorbike, and discussed the start of his nickel-plating tasks.

For this Rust to Rrroarr project, he has decided on a nickel-plating finish instead of chromium for his AJS. In this part two of the six-part series, Peter describes his nickel-plating process

The Shed magazine February/March 2025 issue 119 on sale now

On the road again – new life for old caravans

The allure of a classic caravan can be strong, and many of these gems are being lovingly restored – in fact, Beach Hop even has a prize for the best retro caravan.

In this issue, we showcase three very different caravan restorations—one by a man who owns a company that has been building caravans commercially since the 1950s and is now a household name in caravans and Motorhomes.

The second is a lovingly restored 10-footer that started off a real basket case, and the third, well, friends christened it a turd emoji when they saw the project bought by Marty and Zoe.

Their caravan was destined for their annual pilgrimage to Beach Hop, where thousands gather to show off their super-primped or lovingly restored classic vehicles and caravans

Merry Christmas from The Shed

The Shed team is taking a few weeks’ holiday from the work computer and heading to the beach shed for some kickback time.

So. Merry Christmas and have a wonderful summer holiday to all our readers, followers, and fans. Enjoy this special extra time in your workshops and we will be back posting projects again mid to late January.

Have fun, be good and be careful out there.

From Rust to Rrroarrr video – part 1

Out of the shed and into the sun – part 1

After storing his bike for 50 years, Peter has begun t o restore it. He doesn’t want his bike to look flashy and new; he just wants it to run well and look the part.

In The Shed magazine December/ January 2025 issue 118, we begin a six-part series on the restoration of a 1952 AJS motorbike.

This series of videos will accompany each article from the magazine.

My car the barbecue

A mobile barbecue built out of an abandoned Holden Statesman? Why not. This clever conversion by Scott Edwards, a former freezing-worker-turned-motor-mechanic, was the pin-up attraction at a car, bike, truck and boat Show Day held in Riverton, the popular coastal resort town about 32 km west of Invercargill.

Scott is currently completing an adult motor mechanic apprenticeship but has always had a flair for anything to do with engines. He began early. Scott’s partner, Nicola Swain, says his mother had told her that Scott pulled apart every toy he got as a child, then put them back together again to see how they worked, before he played with them.

DIY audio utopia

I’ve always been interested in music and hi-fi and always thought the best scenario for serious listening would be a dedicated sound-proof music room where you could listen at all hours of the night at any volume without disturbing anyone. A man cave for want of a better term.

I was lucky enough to buy a house with a large detached garage which the previous owner had built for his automotive engineering pursuits. At 13m x 5m, this is unusually large for where I live in London and would never get planning permission nowadays, of course.

The garage is a single-storey prefab of concrete construction with concrete corrugated roof panels, which was common in the 70s. For many years, the garage was just a storage facility and rubbish dump until I finally got around to transforming it into a music room and art studio for my wife (always good to have a guise for spending large amounts of time on a DIY project – I’m doing this all for you, my darling).

Small vehicle, large challenge

The miniature Land Rover is called a Toylander and two lucky grandsons in Australia will soon be taking delivery of a toy that most kids only dream of. Toylander is based in the UK and sells plans and kitsets for a variety of vehicles. Graham came across their website and bought a set of Land Rover plans on impulse, thinking he could knock one up for one of his grandson’s birthdays.

Rather than being a quick job, the project got under his skin and became a bug that has seen the house renovations put on hold, the new shed delayed and a couple of birthdays slip by in the year and a half it has taken to complete.

Although the Toylander plans are comprehensive and highly detailed, Graham’s version has gone far beyond the basic instructions.

Steampunk toys

A steampunk toy (for want of a better term) combines two passions of mine. I love making things that are a bit different, even a bit quirky. Something that stands out from the run of the mill stuff that you buy at the shops. Secondly, I enjoy the challenge of bringing together bits and pieces to make seemingly disparate objects into a semi-plausible whole toy. Steampunk toys give me the opportunity to do both.

The Shed magazine December/January 2025 issue 118 on sale now

Full tilt with Dynamite Dave.

Dynamite Dave Alexander is a self-taught doer, with an eye for detail, unquestionable discipline, and a passion for motorsports. He’s been making things since he was a nipper, and has never stopped. He was raised on a remote Hawke’s Bay farm, where the shed was his university.

Dave says he “grew up doing it”, working alongside his father Neil, learning how to keep the property and equipment maintained and running. His first job was welding all the farm gates. His next was putting in a box-section chassis for a 1942 Willys Jeep, which served as the farm’s workhorse.

At 18, Dave commenced his first customisation of his Mk ll Zephyr, installing a V8, dual headlights, and Vauxhall tail lights. Since then, he has restored, driven, and raced an impressive list of classic muscle cars, scratch-built stocks, rods, and record-breaking Bonneville salt cars.

Now – at 70-something – this multitasking, project-a-holic is closing in on his latest quest: to break 262mph (422kph) at Bonneville in his shed-built, RB-powered Lakester – a project that has been close to a decade in development.

Dave says, “I guess I could be playing golf or in the pub. But you have to do something to get you out of bed in the morning, to keep the old man out.”

Building a potting shed

Among small buildings you can create without council building consent, a potting shed is very handy. The fact the builder agreed to put up this structure to get the gardening tools out of his shed is another story.

If you can possibly choose a flat site, do so. In this potting shed, the only site available was on a hill which meant a fair bit of work for the builder because of the extra labour and time.

Then in order to avoid the need for a building consent, measure the site up to ensure the 10 m2-or-less potting shed is no closer to the boundary or to a dwelling than its own height. In this case, the boundary is nearby but there are no dwellings close by to worry about. Here the original idea was a three-metre long building but it had to be shortened to 2.1 metres because the boundary was closer than first thought.