Free yourself from the grid with an old washing machine

By Ray Cleaver

Photographs: Rob Tucker

[first published in 2006]

Ever thought of creating your own electricity? It’s a challenge a number of New Zealanders aspire to these days, as rising power prices and possible insecurity of supply bring out the Kiwi leanings towards independence and DIY.

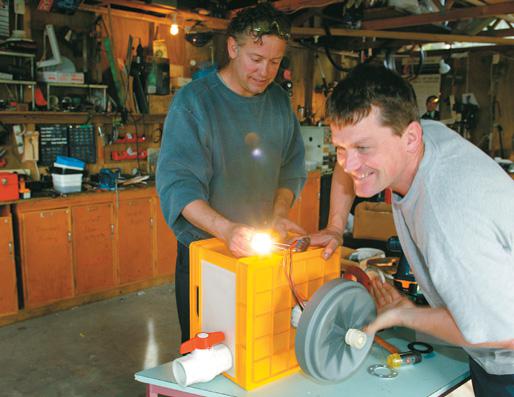

And how to do it? A small stream, a broken washing machine, a shed and you’re away. Well almost. But it is the basis of the innovative home hydro created by Michael Lawley of EcoInnovation in Taranaki. He uses the SmartDrive from old Fisher & Paykel washing machines as the power source driven by water, which could be from a stream on or near your property.

Creating our own power through water turbines, wind generators or solar panels is increasing in popularity, especially among people on small blocks of land. The most efficient systems are water-driven turbines, which run 24-hours-a-day with outputs from 200 to 1000 watts or a kilowatt.

The average house in New Zealand uses 24 kilowatt hours of electricity per day (one kilowatt of continuous use per hour – this is like running a two-slice toaster all the time). If you add in solar water heating and gas cooking as other sources of power, Michael Lawley says you can meet your own needs with a Pelton wheel turbine supplying 300 watts from a small stream. On the right site, you could generate 1500 watts from these turbines.

In 1876, in the California goldfields, carpenter Lester Pelton invented the turbine using cunningly engineered small buckets, divided into two halves, designed for maximum efficiency for the water flow. The Pelton turbine, a step-up from the water wheel, is still widely in use today.

You can build a Pelton turbine yourself for a low cost, creating the electricity through a Fisher & Paykel SmartDrive washing machine motor by using it as a generator.

Michael Lawley and his small business EcoInnovation has turned production of these low-cost but efficient systems into a thriving business, exporting either parts or complete generating systems all over the world. Legally anyone can build these systems. The amount of water involved can mean no RMA consent is needed and as long as the output is under 50 volts no electrical regulations are in force.

Simple

The principle is simple. A disc with a circle of Pelton cups is mounted in a box and the incoming water is concentrated into a jet to spin it. A shaft runs through the box on two bearings and spins a SmartDrive motor which creates the electricity. This runs through a small rectifier which alters the 3-phase AC into DC. It can then be run to batteries for storage or used direct. The DC current is run through an inverter to change it into AC for domestic use.

There are some crucial tolerances which must be taken into account, such as the amount of water flow and the head. Head is the pressure that builds up from the drop in height from the water inlet at its source down to the outlet. Other tolerances relate to the pipe used to carry the water to the turbine. Friction in the pipe will impede the water flow. Loss of flow speed and pressure because of friction will increase rapidly the smaller the pipe. The bigger the pipe the better the flow and pressure will be. The water flow in litres per second and the water head are important to determine the optimum size of the output nozzle (jet) that directs the jet of water onto the Pelton wheel.

The jet must hit the Pelton buckets in the right place and the Pelton wheel must be balanced to prevent wobble and vibrations. EcoInnovation have developed a turbine with buckets especially injection moulded for the job, bolted to a disc and balanced. This is available as a kitset together with the bearings, shaft and jet nozzles.

EcoInnovation publish a manual for those who wish to use their system. It is a comprehensive book with charts for calculating water flow, pressure and Pelton wheel size as well as the finer points of assembling SmartDrives into generators and deriving the best performance to suit individual sites.

Michael Lawley and his production manager Ken Kowalchuk recently built us a demonstration turbine using very simple products and tools.

Plastic crate

The box used to house the turbine was a plastic Cube Crate from The Warehouse (350mm x 350mm x 280mm), costing about $7. For the generator you have a choice. You can dismantle a SmartDrive-powered washing machine yourself and use the parts, or buy the parts ready-to-use from EcoInnovation.

An electric motor and a generator are basically the same. Michael says these SmartDrive motors are well-made and last a long time, even if they have had long service in a washing machine.

Dismantling the washing machine is a very simple job. You are looking to use the motor, the shaft that runs through it, the bearing assembly, the rubber seal on the shaft and the large round galvanized washers.

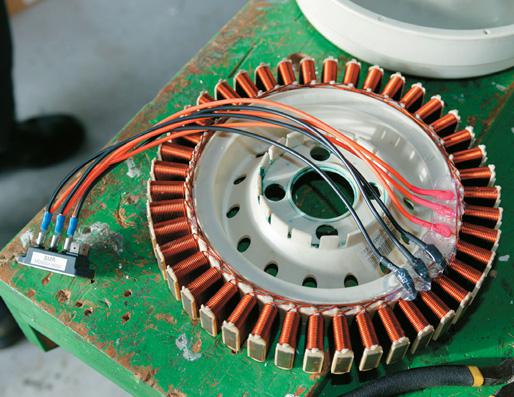

The motor itself has two components, a stator and a rotor. The stator remains stationary and has the looms of wire, and the plastic outer rotor has the magnets. The two can be split apart by holding the plastic rotor cap on the end of the shaft and spinning the rotor off the stator.

There are pitfalls if you source your own motor:

* Watch for radial cracks in the stator.

* The bearing assembly with its plastic fins must be cut down to fit into the box. The plastic is then machined down to expose the aluminum fixing channels. These channels are tapped to fit two-inch long x ¼ inch BSW bolts to fix the assembly to the box.

* Check the width of the wiring on the stator. If it is 1mm thick, you can use the motor as is. Otherwise you will need to alter the stator wiring configuration.

* You will need to purchase two new shaft bearings and throw out the old ones. They are standard bearings, 47mm outside diameter (OD) and 25mm inside diameter (ID). You can buy a pair from an engineering or bearing retailer. EcoInnovation also has bearing kits available.

Assembly

Now for the assembly. before the home hydro turbine was assembled, the crate was first stiffened for strength. Michael found the best material was plastic kitchen cutting boards (again from The Warehouse for little cost). Plywood sheet would be excellent too. Saw one into a square and silicon glue and screw onto the inside of the bottom of the crate. Similarly, strengthen the water inlet side to provide purchase to fix the ball valve and nozzles to; this area is under some pressure so it needs to be strong.

If you have removed the bearing assembly yourself from a washing machine (and cut back the fins), tap the four holes on either end to take eight 25mm x ¼ BSW bolts to attach to the crate and the stator on the other end. These must be stainless or galvanized.

Use the washer that comes with the motor as a template. Drill the main hole in the crate for the bearing assembly with a keyhole saw and the four holes (8mm) for the bolts that hold the assembly in place. (Note: you will need four of these washers, one for each join of the assembly).

Insert the bearings into the aluminium and plastic bearing holder by press fitting them. Next, insert the stainless steel 25mm shaft through the assembly. Adding Loctite between the shaft and inner bearing race prevents the shaft spinning in the bearing. Screw on the large bearing nut that comes with the shaft, but no more than finger-tight.

To prevent water from travelling along the shaft and into the bearings, Michael uses a plastic screwtop jar and a “slinger”. The slinger is the original watertight seal from the washing machine that is intended to prevent water reaching the motor via the shaft. It is employed here to do the same job.

This slinger grips the shaft tightly and allows water that runs along the shaft to be slung off. The plastic jar is fixed to the base and a 50mm hole cut in the bottom, with a hole in the lid slightly bigger than the spacer sleeve. Secure the jar, bottom first, with the rubber gasket or silicon. Now slide the spacer into position with the slinger fitted to form a tight seal within the bearing assembly. Screw on the lid and position the Pelton wheel loosely in place.

Now for the jet. For maximum efficiency, the buckets are split into two chambers. The water jet must be positioned so it hits the bottom Pelton bucket 10mm up the splitter. The hole you drill for the water inlet must be centered on that spot. The two-inch ball valve screws through a 50mm brass nipple onto the plastic jet assembly. When screwing this onto the crate, use a bit of plastic cutting board to strengthen the fitting, as this area is under some pressure.

Jets size can vary from 5mm to 22mm, depending on your water head. If you have a lot of water, you can put in two jets, one hitting the bottom of the Pelton wheel and another hitting the top from the opposite side. Once the jet is in position you can fine tune the position of the Pelton wheel by varying the lengths of the two spacers or by adding washers. Bolt the spacers together with nut and washer on the shaft end. The rotation of the wheel will ensure that it does not come loose in use. Rotate the wheel to check that it moves freely and turns the shaft.

Electrical

Now for the electrical side of the operation. Before attaching the SmartDrive motor, you may need to rewire the stator to reduce the voltage. You can select a SmartDrive stator suitable for voltage outputs of 12, 24 or 48 volts. Remember over 50 volts can be dangerous. The actual output of your system will be influenced by a number of factors not least what model motor you have (there are four types of SmartDrive motor available) and the rpm of your system, determined by the water pressure and flow. The manual gives instructions for this.

If you have sourced your own SmartDrive motor and it has the thicker 1mm wiring on the stator, you can use this, as is, for 24 or 48 volt applications. From this you will get a maximum power output of 400 watts at 24 volts, or 700 watts at 48 volts, again depending on the amount of head and water flow. This is fine for most low output systems. If you want a higher output you need to get some specialist rewiring done.

SmartDrive motors are wound in three-phase. The six connections on the

SmartDrive stator correspond to the two ends of each phase. Three-phase motors and generators can be configured in two ways according to the performance required. These configurations are referred to as either Star or Delta from the wiring diagram. From the factory, all SmartDrive motors are connected in Star. A Delta configuration gives you more power at higher speed while Star will create more power at a lower speed but cannot generate as much power.

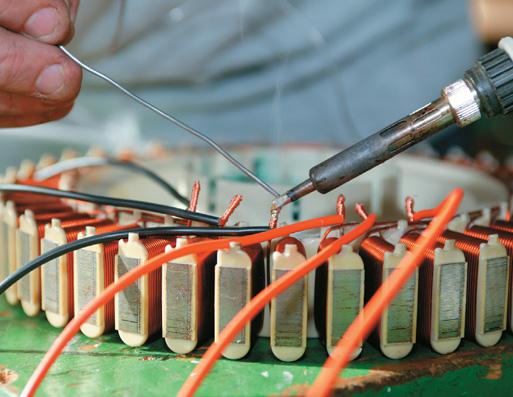

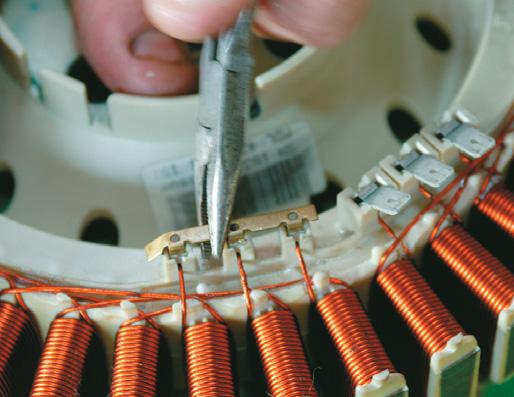

There are six lugs where the wiring looms emerge from the motor. Knock off the plastic lugs and clips and expose the six ends. You need to scrape the lacquer insulation from the ends of the wire and extend them by about 200mm by soldering extra wiring to allow them to connect to the rectifier.

To configure the wiring for Delta, counting off from either end of the six wires, join ends 1 and 5, 2 and 6 and 3 and 4 together. This gives you three ends to attach to the three AC pins on the rectifier.

To configure for Star join ends 1, 2 and 3 together. Wires 4, 5 and 6 you connect to the three AC pins of the rectifier.

Once you have affixed the additional leads liberally coat the exposed joins in hot glue or silicone to secure them.

To change the current from AC to DC, you will require a rectifier. These are relatively inexpensive items and can be created from three single-phase rectifiers or you can use an automotive-type rectifier as used in car alternators. The rectifier bolts onto the crate behind the SmartDrive motor. To change the current to single-phase 230 volt AC from battery DC voltage you will need an inverter.

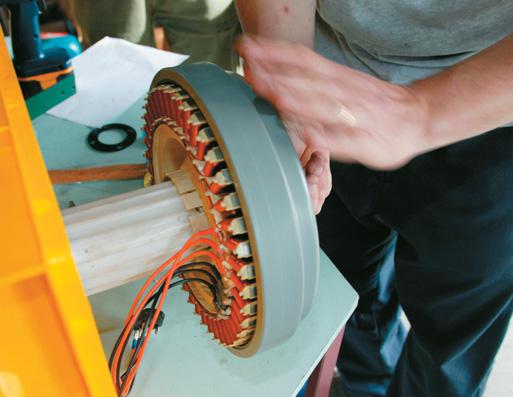

Bolt the stator to the bearing assembly. Attach the rotor by turning the white extractor knob. Michael usually slides a piece of Perspex through grooves onto the open top of the crate (which becomes the side when the crate is tipped over for use). This prevents water flying everywhere when the Pelton wheel is spinning and also gives you a window to check all is going well.

You are now ready to leave the shed and connect the turbine to your water input. It is recommended to put some solid legs onto the crate to ensure it will not move when in place.

House power

If you are powering a whole house at the end of the system, you will need a voltage regulator to control battery charging and divert excess power, an inverter to change the current to AC, deep-cycle storage batteries and a diversion element. The diversion element is to burn off excess power, particularly at night. You can divert this power through the right kind of hot water immersion element.

The cost of your wiring from the turbine to the batteries depends on the distance involved. Voltage drop over the distance will be a consideration in determining wire size. The manual from EcoInnovation has comprehensive formula for determining the optimum cable size matched to your system.

The cost of pipe to convey the water to the turbine depends on both distance from the inlet and size of pipe. Remember, the larger the diameter of the pipe, the less the friction. Typically, a pipe regularly used is 50mm, but would be larger for low-head sites. It will also depend on your budget and how much water you have available.

Attach your water input and wires to your battery bank and wave goodbye to power bills.

Of course there is more to it than that if you wish to go it alone and create your all own electricity. This system is ideal for constantly charging a bank of batteries that in turn supply 230 volts AC power via an inverter. It can be supplemented with other power sources such as solar or wind if required. However, unlike these other systems the hydro generator will run 24/7 so long as there is water. If you can cut down your demand by cooking with gas and add a solar hot water collector you will have more electricity to spare for other needs.

While total isolation from the power grid may be a dream for most, there is a lot that can be done to cut down on your homes reliance on mains electricity.

To make your house energy efficient you should look at:

* Compact florescent lighting.

* Good energy-efficient refrigeration.

* Gas cooking.

* Good insulation and double-glazed windows.

* Sparing use of appliances that produce heat.

* LCD flat screen TV and computer.

* Solar water heating with wood-fire or gas backup.

In short, there’s a whole world of alternative energy systems out there, a challenge for any sheddie. Not only is creating these systems fun, but there’s money to be saved and many skills to be picked up along the way.

3-PHASE DELTA AND STAR CONNECTIONS

There are two types of connection that 3-phase motors and generators can be configured into; these are commonly referred to as Star or Delta.

How the unit is connected has a significant bearing on the performance of the generator. Each unit can therefore be connected to have one of two types of output.

All smart drives as connected in Fisher & Paykel washing machines are connected in Star. This is easy to verify as a three-pronged brass clip forms the star point.