A customised caravan is the perfect mate for

a Mini Cooper S

By Ray Cleaver

Photographs: Rob Tucker

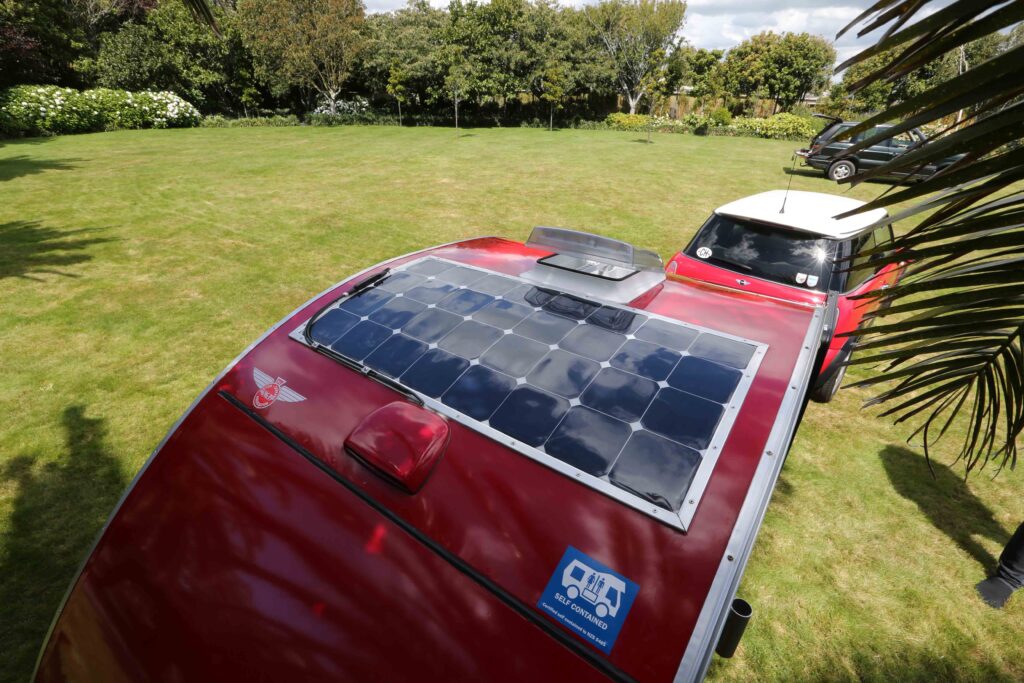

What do you do if you want a caravan but drive a Mini? You make one to fit. That’s just what Michael Wolfe of New Plymouth did – turning out a real dinky little teardrop-shaped caravan that matches his 2004 Cooper S and has all the mod cons for a decent holiday.

Michael saw pictures of little campers on the net and decided that was what he wanted – a cross between a caravan and a tent.

“I got some ideas from little caravans online and decided to go a bit more high-tech,” he says.

He built it to have the same lines, wheels and colour as his car and it looks just the part.

“I never really planned it in detail. I sketched it out originally and a lot of the construction I worked out as I went along.”

The chassis was welded together with Michael’s trusty old MIG welder using 25 mm x 50 mm galvanised box section steel, with a floor pan of 2.4 metres by 1.2 metres.

The underneath is sealed with 3M rubberised undercoating. For the floor he used 19 mm first-grade construction ply.

The caravan frame is 19 x 45 mm dressed tanalised pine, with 19 mm polystyrene glued into it for insulation. The inside lining is a special ply used in caravan construction with a laminated coating on one side.

Keeping things light

In a clever move to keep the weight down the exterior cladding is the aluminium and plastic composite you find in modern signage which is very light. It is called Signboard and has a plastic centre with 0.3 mm aluminium either side, baked with enamel paint.

The interior and joinery is American oak and all is secured with stainless steel screws. He imported the two side doors, with their piano hinges, from America.

The wheel track is identical to the car and it “follows beautifully”. It did too. Sitting in the car you weren’t even aware you were towing.

His Mini is a 1600cc supercharged model so he has no shortage of towing power.

Michael picked up the wheels from the wreckers, from a Mini of course, to match the car and he put in Duratorque suspension.

Empty out the awning and the furniture and there’s a comfortable double bed which also can converted into a comfortable seating area.

Bespoke kitchen

The rear door of the little caravan opens up to reveal a beautifully made little kitchen. At the push of a button a two-hob gas stove slides out. Very classy.

Michael used a 12-volt VW rear window wiper motor to power the sliding stove system.

He made up the mechanism with relays and microswitches. The stove slides out on ball- bearing sliders used in kitchen drawers, which he modified for a longer extension.

There is a built-in 12/240 volt, 15-litre fridge. A hidden 4kg LPG bottle provides the gas needed. A workbench, sink and cupboards are well planned and there’s even lighting for night cooking.

The oak joinery is first class and the kitchen has 1960s Duraware plates and cups ready for use. Everything is secured by little brackets.

The project took Michael from February to Christmas one year, working in his spare time.

He is a mechanical design engineer who works as an auto restorer looking after a collection of classic cars owned by Bryce Barnett (see issue 71, February/March 2017, of The Shed).

He had the skills to create almost every stage of the project.

Electronic technology

Electronically speaking the little caravan has technology that’s right up there. On the roof is mounted a curved 100-watt solar panel. This charges up a 12-volt, deep-cycle house battery. There is a 240-volt inverter and the system handles 1200 watts.

This powers a computer, television, lights, a DVD player, fridge and radio. Michael has internet access and speakers are set into the wall.

His son Nickolai (17) is very computer savvy. He took apart a laptop, removed the screen and mounted it above the bed in the caravan. He removed the DVD player and mounted that below the monitor and made the keyboard wireless. There is also inside and outside lighting.

Self-contained

It’s freedom camping all the way for Michael. The caravan is even certified as self contained. It carries 75 litres of drinking water and has a tank for a further 75 litres of grey waste water.

There is a chemical toilet and a shower with electric pump whereby you stand in a tray in the

awning for washing. There is a separate canvas cubicle for these ablutions.

A customised awning attaches to the side of the caravan and is 2 metres x 4 metres and 2 metres high.

The awning has room for two camp beds, a table and four chairs. Michael can set up the awning in half an hour and everything stows away in the caravan for travel. The awning and the upholstery was made by John Reumers of Reumers Trim and Upholstery.

Michael said the most difficult part of the job was the kitchen: “That was a very fiddly job— space was at a premium.”

Finishing touches

For a finish Michael painted the caravan with a two-pack, a BMW Chilli Red to match his car. On the back of the Mini is Cooper S and on the back of the caravan, in the same lettering, is Camper S.

It has a jockey wheel for parking and Michael said putting a tow bar on the Mini was quite easy. “There was a nicely situated hole where the reverse light was.”

The caravan cost Michael $15,000 in material and parts and he estimates he spent 500 hours of labour.

“All up it would have cost me about $25,000 but it was well worth it. I love it.”

Michael and a mate took the caravan on its maiden voyage last Christmas to the Coromandel.

“It all worked well, no problems,” says Michael, who is looking forward to many holidays to come.