Headwinds in the foundry

The end of an era for Austins of Timaru

Our main feature this issue is the story of a family firm that has provided a good living for at least two generations, building up an impressive skills base while manufacturing essential farm machinery for more than 90 years. The Austin family has run a foundry in Timaru for 93 years. Ken Austin, grandson of the founder, says the business has faced increasing headwinds since the Covid-19 pandemic, so he has tested the winds of change and decided to close down. The Shed visits to celebrate their technical foundry skills, the likes of which we may never see again in NZ.

“Finally, there is the fun part – with molten metal, sparks, and drama.

The lumps of cast iron and coke are placed in the furnace and fired up. As the coke burns and the temperature increases, the cast iron melts and sinks to the bottom. The furnace operator removes a plug in the wall of the furnace (with an appropriately long bar) and the liquid metal streams into the ‘buggy ladle’, which carries the molten iron to the mould. This was designed in 1956 by Bob Austin. Rotation of the ladle’s handle pours the metal into the casting cavity through a channel in the sand called a runner or downsprue. When metal appears at the vent holes, the pour is stopped.”

Make a roll cage

Welding chrome molybdenum

If you are about to go car racing this summer then you must have a roll cage fitted to your vehicle and it is possible for you to make this yourself.

Welding pipe and welding chrome molybdenum (chrome moly) are two essentials in making a roll cage in a race car. Frank Wigg at Race FX in West Auckland (known now as Wigg Motorsport) likes working with chrome molybdenum and says it is not that hard to weld.

An experienced welder in the motorsport world, Frank estimates he has made more than 100 roll cages.

“Make sure you have plenty of gas flow when welding chrome moly so there are no bubbles or porosity in the weld. Good gas assists good penetration. You are actually melting both tubes and they are fusing together. They should be just about able to fuse without filler rod. If they do that and you add filler rod as well, this will give you maximum penetration. You know it’s a good weld if you make it clean and tidy and right around the pipe. If it’s just sitting on top then it’s not a good weld. Chrome molybdenum welds beautifully, and I prefer to weld this any day.”

Make a crossbow – part 2

Crossbows – still very old, very cool, and very lethal

Our crossbow build is starting to hit its straps this issue with the butt, the prod and more really starting to take real shape. It’s getting to that stage where maybe we need to bring in an expert to make sure we get things made just right with the correct material etc, and we are so glad we did.

“At this point I went to see Tetsu McNeil, bow maker, sword maker, armour maker, costume maker, artist, and writer. I had many questions, particularly around the construction of the prod – about materials, laminating, fixing, and removing for convenience; in two parts or one; length, breadth, and height?

“That’s a stone-throwing trigger you have there,” was McNeil’s first comment when he saw what I’d brought with me.

“Oh, can I still use it” – were my doubts about the trigger being confirmed?

“Possibly; let’s see the rest of it first.”

He looked over my model, my sketches, and my rimu chassis. “Good idea to use foam board for the model, but I think you need a proper trigger.”

ATV mower project – creative mechanical engineering

‘The farmer’s way’ – 21st century style

For Alex van Dijk, owning and living on a lifestyle block is an incredible privilege. Alex and his wife, Anke, relish this lifestyle since they were married, and they wouldn’t want it to be any different. Living on the outskirts of Auckland, they are close enough to the city to enjoy its events, restaurants, and beaches, yet far enough to enjoy the peace and connection of our rural community.

Unlike many lifestyle-block owners, I have, to date, refused to buy a ride-on lawn-mower, despite our very large lawns. This is because I have always valued the exercise gained from pushing a manual mower rather than sitting on a ride-on. As for the paddocks, Anke’s amazing stock management has meant it is only in the late spring and early summer months that they occasionally need the help of a paddock mower to keep the grass under control.

“For a few years, we did without a paddock mower, and more or less managed OK, occasionally borrowing the neighbour’s topper. However, eventually the call to own a mowing solution became stronger, and I was again in need of another shed project. A quick look at pricing for a new or second-hand quad topper confirmed that making something was the way to go – new toppers typically cost $4000–$6000. I figured that I could probably put together a good one for around $1000, plus my time.”

Max’s shed – part 1

Max and his dad are building a shed

Max is 28 years old and has a business making planter boxes and his business is thriving. So much so that now he needs his own workshop/shed to put all the boxes together so he can keep up with demand. This is part one of the journey to build a backyard shed for Max.

“G’day! I’m Max. I came into the world of my mum and dad (Helen and Geoff) in 1995, as their lucky number two.

Fun fact about me is I was born with Down Syndrome, or Trisomy 21, as it is called in France, where I was born.

Mum and Dad keep the ball rolling by trying to keep me busy and learning, so my days are filled with activities such as painting classes, Special Olympics swimming practice, house cleaning, lawn-mowing, and making planter boxes. Dad has designed a planter box made from fence palings, and he cuts kits for me to put together. He has made an aluminium jig for me to use so I pre-drill and hammer the nails in the right places. Then I paint the boxes, fill them with soil, and plant them with herbs or annual flowers. I have sold about 70 planter boxes to date and, while they don’t make a great profit once the time and materials are added, assembling each one grows my woodworking skills and keeps me off the streets.”

Software test

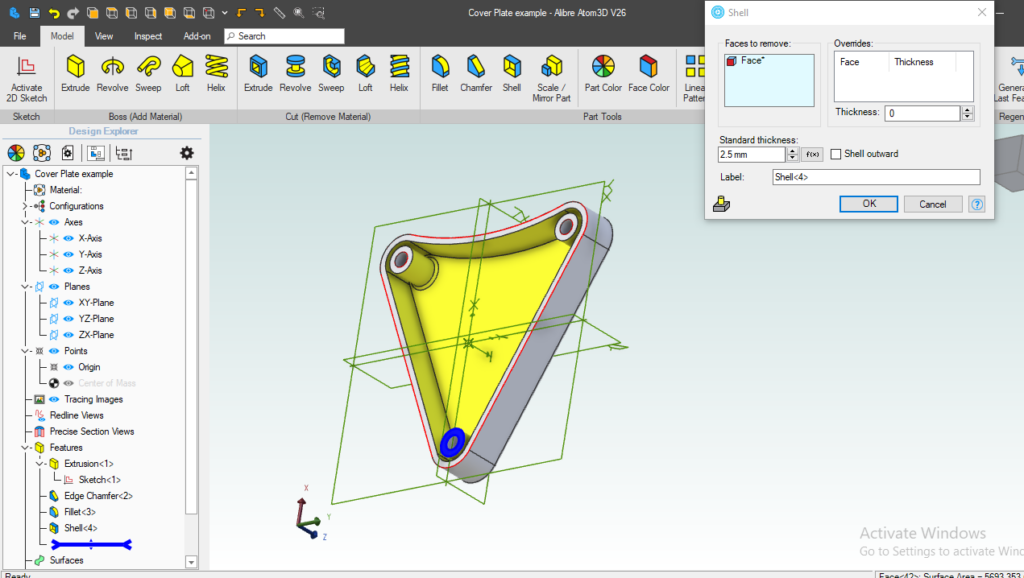

Alibre 101 – part 8

This is the final instalment on learning how to use this design software, Alibre Atom 3D, so with all the foundation skills mastered, it’s time to let your imagination run wild!

“In the previous issue of The Shed, August/September issue 110 (and part 7 of this series) I described how to create assemblies.

I was left wondering how many imaginative readers figured out that they could create a Lego block in the Alibre Atom 3D program and, using the assemblies capability, create their own virtual Lego models.

There are advantages. Firstly, you do not have to purchase any blocks so it is cheaper and, secondly, there will not be any chance encounters between stray blocks and your bare feet!

Joking aside, it is possible to do exactly as I have mentioned above. In this article, we will look more closely at what can be done with assemblies as well as have a quick look at the shell function and how to get fancy with lettering.”

Off the grid

Five ways for sheddies to address the future

In the previous edition of The Shed, the editor lamented in his editorial that our lack of activity from one and all to attack climate change was giving him sleepless nights. Murray Grimwood our Off The Grid columnist heard the call and suggests some actions our readers can undertake to commence doing their bit to help our climate predicament.

“In response to Greg’s editorial in The Shed issue 110, lamenting our lack of global climate action, I offered to compile a useful sheddie to-do list.

Then I thought some more; our predicament is a multi-headed beast; in addressing climate only, we run the risk of making other matters worse. Discussing the whole, though, takes more than one article, so here’s a ‘once over lightly’ before we get on with the to-do list. I’ve also suggested some further reading in a side panel.”

The Shed shrink

There’s a new rumble in Christchurch

It’s always a good day when you come across a good bugger and Mason Simpson is one of those. Mason undertook a fundraising mission driving a Tuk Tuk from Auckland to Christchurch to raise money for charity. His 1200km 12-day solo roadie fundraiser raised $12,000 in donations. The trip gave him the opportunity to visit rest homes, skateparks, shopping malls, and, in particular, schools. He says he felt humbled by others’ stories of struggles and hardship.

“Mason described his journey as a personal one and admitted that some days were gruelling away from the spotlight. Spending 13 hours on the lonely roads with only his own company in that little cabin meant he had to be in the right head space.

Mason freely admits he’s an old soul, and has often had friends his own age who are struggling with mental illness come to him for advice.

“We can all be affected by it,” says Mason. “I wanted to raise awareness using my passion for small-capacity motorcycles, in particular.”

Building a router table for a plunge router

Good tools are not cheap, so it can be important that they are versatile

The always enterprising Coen Smit is a consummate sheddie and strives to create great shed projects and versatile tools to help him achieve the best results for those projects.

In this issue of The Shed, he describes how to make a mounting table for your router to make it even more versatile and useful.

“One of the predispositions that drives me as a sheddie is the belief that the more versatile I can make the tools I own, the better.

I have owned a Makita plunge router for quite a few years, making use of it now and then. However, given the cost of buying it, the use I have made of it hasn’t really justified the outlay. It’s just been one of those tools that are good to have if you like woodwork. I also have a smaller router that is less cumbersome and is therefore called upon more often, further reducing the use the Makita is put to.

To remedy this, I decided to build a plate for the plunge router that can be clamped on my Black and Decker workbench. The plate is a section of Formply left over from a box trailer refurbishment. It has a nice smooth surface, is robust, and will not warp or twist.”

Electronics – Ghent Maker Faire – part 2

Inspiring passion through education and hands-on experience

In this second part of the Ghent Maker Faire, Enrico Miglino introduces another series of stands. These represent the real soul of the event and some notable groups that have elevated the ‘art of making’ to a fascinating professional pastime.

“At the fair, visitors of any age could test, personally experience, and discover what educational and training experience fitted their interests. This active participation was available free.

Most of the proposed activity projects – workshops, maker camps, events, and open labs, to mention just some of them – are harmonised with the traditional educational paths; the STEM educational projects extend to public schools, libraries, and some universities throughout the whole country.”

Hybrid hydraulic lifter

Brain wins over brawn when it comes to tackling heavy-duty lifting

Bryce Clifford is a busy sheddie, so busy in fact that he has not found the time to write a workshop article for the magazine for, well, ages.

Time to address that absence and here Bryce admits he’s not getting any younger and shares with us how he made a hybrid lifter to help him avoid serious injury when moving and lifting heavy machinery in his workshop.

“Now that I am getting a little long in the tooth, and several parts of my ageing anatomy are feeling the effects of a life well spent, it has dawned on me that I shouldn’t be lifting and lugging heavy machinery as often as I do.

What I needed was a small, mobile, lightweight lift with adjustable height, good wheels, and a low, low price.

I have several lifts in my tiny workshop, but alas they are long, heavy, depleted of wheels, and always have small English two-stroke motorcycles sitting on them, which makes them all somewhat redundant. A better plan was needed – and quickly.”

Book review

Kiwis on Harleys By George Lockyer

Our reviewer Chris Hegan is something of a Harley Davidson fan and was excited to be reviewing this Kiwi book on Harleys. Whilst he adores Harleys, he has some reservations about this new book.

“When I opened George Lockyer’s Kiwis on Harleys, I expected a fair bit of that sort of story; the ‘why’ of the Harley-Davidson legend.

Not a bit of it. For a book about and full of such brilliant, desirable, and exciting things as Harley Davidson motorcycles, this one is puzzlingly free of any such rhapsodising. Lockyer almost seems to have missed the whole point of having one. There are many, many pictures of stunning Harleys and gleaming parts of Harleys, but only four with a Harley doing what it is made for: being ridden – and one of those photos is of a bison.”

Steampunk armoury

One man’s passion provides a treasure trove for collectors

Warren Phillips is an interesting sheddie for sure. He was working as a camera technician when he started selling antique cameras, used magazines, and framed car advertisements at Christchurch’s large Riccarton Market. Warren’s source of car ads was magazines of the ’60s and ’70s, such as Playboy and The Saturday Evening Post, in which US automakers would regularly take full-page ads to announce new models. One day he brought along a Steampunk gun he made for a bit of fun and well, things have really taken off for him in his new venture.

“A couple of years ago, Warren noticed that increasing numbers of market visitors walked past his stall with their eyes firmly on their phones. To attract their attention, he made a steampunk musket, incorporating a rifle stock, copper pipe, and parts of antique cameras. The gun was a felicitous combination of two of his great interests: military history and photography.

Warren’s work as a camera technician and gunsmith had given him the metalworking skills that were essential for the construction of the interestingly complex imitation firearm. The gun attracted a gratifying amount of interest from the strolling punters and was, in short order, sold. He could see that he was onto something. More were made and sold. One customer has bought three.”

Working with clay

A career built on passion, hard work, and an abundance of ingenuity

Sheddies come in all shapes and sizes and passions aplenty. Meet Trevor Wright, he likes pottering about in his shed. As a lad in Auckland, Trevor spent time visiting NZ Dutch artist Theo Schoon, who was a friend of his uncle.

After a visit to West Auckland’s Crown Lynn to get some clay, Theo literally dragged a couple of apple boxes filled with the clay, wrapped in canvas, to his home. When Trevor and his uncle visited the next day, Theo showed Trevor what you could do with it. He rolled up a ball of clay and, giving it to Trevor, said, “Here, have a play.” That was Trevor’s introduction to the stuff.

“It’s mostly commissions that Trevor does these days. A large and beautiful bowl sits on the workbench, a work in progress. It is testament to the long experience Trevor has of throwing pots on the wheel.

“I used to get up to 23 casseroles and their lids in two hours,” he says, “but there’s people far better than me, far quicker than me.”

Trevor’s philosophy is this: If people say something can’t be done, I give it a go and see if it can. By doing that, I learn a terrific lot.

All Trevor’s work has paid off, as he has enjoyed an international career as a ceramic artist. He has exhibited at the Expo in Vancouver, Canada (1986) and in Yugoslavia (1987).”

Back O The Shed – Spring has sprung

A new season – a time to welcome new friends, farewell an old one, and tackle deferred tasks

Who doesn’t love Spring and The Shed magazine founder Jude Woodhouse sure does. His rural life is full of projects, shed building and farm animals. In his column this issue Jude shares his Spring tales but laments the loss of a good mate of his and of this magazine.

“It’s spring at last! The daffodils are poking their yellow periscopes above the earth, bringing some cheer after the ills of winter. On the hills, I see the lambs bouncing about. The mud is in danger of drying out. The days are longer; we are even getting whole days without rain.”

Steaming on the Weka Pass Railway

… perhaps for the last time

The Weka Pass Railway runs between the North Canterbury villages of Waipara and Waikari.

“At the end of July this year, the locomotive made its last couple of trips on the line before it was taken out of service to undergo a 10-yearly boiler inspection. There is some worry that the cost of the repairs needed may be very substantial and that this may have been A 428’s last time in steam.”

To purchase a copy of this edition of the magazine, head to our online shop magstore.nz