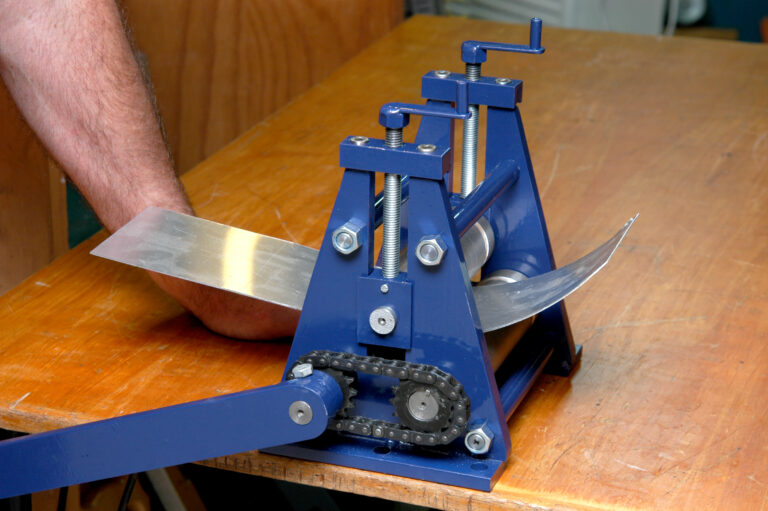

Versatile Hi-Q Toggle clamps

Toggle Clamps

When it comes to clamping, lever-action toggle clamps offer excellent power from a quick and easy motion and they are simple to install for ready access. Toggle clamps have a multitude of uses in engineering, metal fabrication, and woodworking. Hi-Q Components stocks a wide range of high-quality Turkish-made Kukamet toggle clamps including horizontal and vertical actions, latching or push–pull configurations with different mounting options, and even pneumatic versions.