Latest news and features

The Shed March/April 2023 issue 107, on sale now

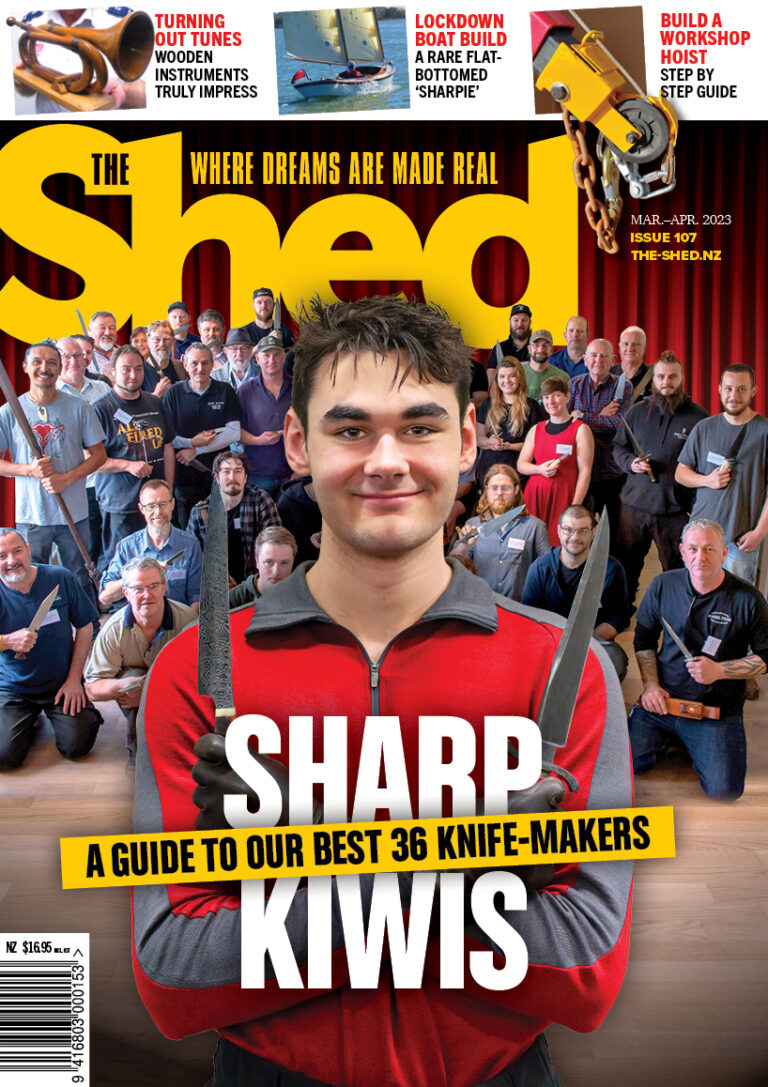

In New Zealand, knife-making is increasing in popularity year by year. If the recent Auckland Blade Show was anything to go by, this pastime is now a full-time career for a large number of sheddies and of enormous interest to the general public. The hundreds who came through the doors over the two-day event are evidence of knife-making’s huge growth over these past few years.

Who are these knife-makers; what separates and what inspires them? Where are they, and what knives and blades do they create?

We’ll soon know more because in this issue of The Shed we profile 36 of NZ’s finest. Read our Who’s Who and Where’s Where in this issue in an extensive rundown of our 36 best Kiwi knife-makers.

Gold fish

The shubunkin goldfish is sometimes referred to as “poor man’s koi” and in China the koi carp is often used to represent yin yang. I have drawn the body of the shubunkin goldfish fish to look like one half of the yin yang symbol (see panel). I then added the fins to suggest and give movement to the piece.

Firstly I took a photocopy of my artwork and stuck it to a sheet of 0.5 mm copper plate with double-sided tape. This is to create templates of the body and fins

Classic Manx Norton flourishes

The legendary Manx Norton was

the first single-cylinder motorcycle

to lap the famous Isle of Man TT

circuit at an average speed of 100 miles per hour (160 km/hr).

Made from 1946 until 1962, the bikes became a favourite of privateer racers and in more modern

times, a popular choice for classic

motorcycle racing.

Today, half a world away from the original Birmingham factory, a small Kiwi company is restoring and supplying parts to Manx Norton owners around the globe.

The Shed January/February 2023 issue 106, on sale now

For this summer issue of the magazine, we thought it would be an idea to keep our readers busy and enjoying themselves in their sheds on rainy summer days.

Our main article this issue “Six Summer Sheddie Projects” is about combining the fun of the summer daze and the annual wind-down with family and friends with the spirit of DIY that drove many of us to a self-sufficiency based around our garage workshops and sheds, and more recently extended into MenzSheds.

Our Kiwi No. 8 wire mentality gave us pioneers such as Sir William Hamilton of HamiltonJet and Peter Witehira of Power Beat with his never-go-flat battery.

Now it’s your turn. We’ve come up with six projects of varying levels of skill, and invite you to have a go at them, or — better yet — put your ‘I can do that’ hat on and improve on them.

A new global distribution agreement between element14 and Analog Devices

A new global distribution agreement with Analog Devices, an international leader in the semiconductor market, has given element14 the ability to offer its customers an increased range of high-quality products for mixed signal and power management.

The new partnership with element14 will offer fast delivery of the Analog Devices range, including the latest innovative products. The broad portfolio of high-performance analogue, mixed-signal, and digital signal processing integrated circuits is suitable for many types of electronic equipment, helping design engineers to create new solutions for a variety of industries, including automotive, communications, consumer, data centres, and industrial automation.

Positive trends for gender balance in the electronics and engineering industries

A new survey on global trends affecting women in the engineering/electronics industry has revealed that, although they still face major challenges, there are positive trends that highlight a continued movement towards equal treatment, regardless of gender.

This is the second survey element14 has conducted that is aimed at shedding light on women’s experiences, career paths, wider challenges, and opportunities in the engineering/electronics industry.

The results show that inequality needs to be addressed to achieve the equal treatment of all, and that women around the world remain underrepresented in the industry and continue to experience various forms of sexism and discrimination.

New questions covering discrimination, sexism, and equality were added to the 2022 survey, as these critical issues were noted as key areas in the original 2021 survey analysis.

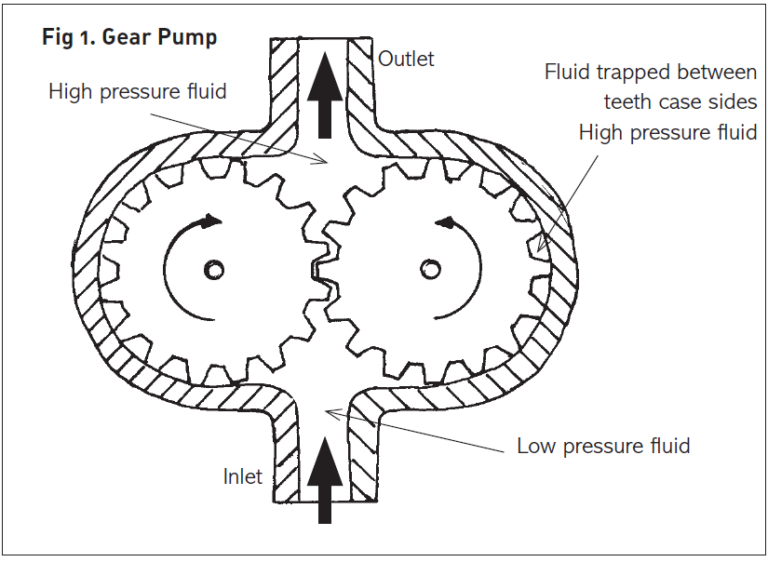

A Primer In Hydraulics

Now that you have a basic overview of some of the components that go into making up a hydraulic system, let’s take a look at a practical application. The wood splitter is a good example.

First you need to determine what you are trying to achieve. In the case of our log splitter :

* How much force is required to split the timber?

* How fast do you want to complete a full cycle i.e. ram full out and full return?

* How much horsepower is available to power the pump?

We will illustrate an example using a single-stage pump with a safety margin of 200 bar (pressure

in bar: 1 metric bar = 14.5 lb/in²).

It must be emphasised that an oil pump does not pump pressure, but flow. Pressure is created by the load on the actuator

Videos of metal shaping and motorbike guru, Steve Roberts

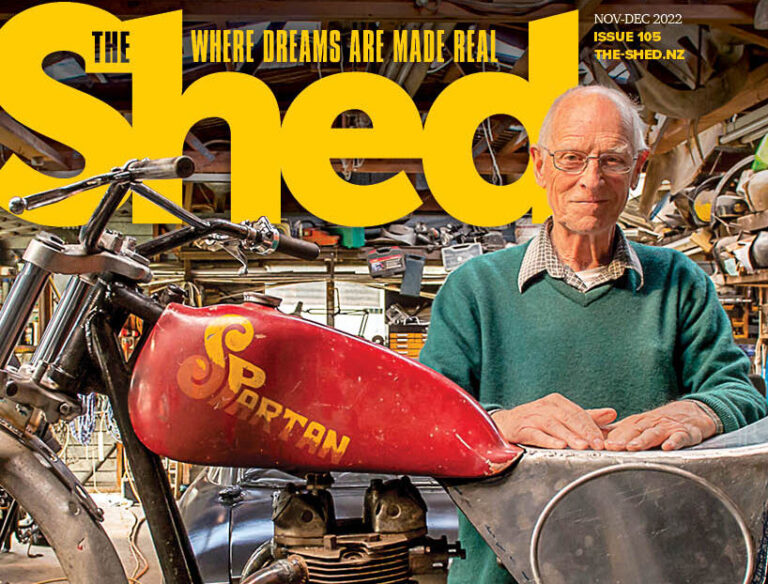

In the November/December issue 105 of The Shed, our cover story is on a Kiwi legend of metal shaping and motorbikes, Steve Roberts.

If you enjoyed that article here is a link to a website that has even more of Steve’s story as well as videos of the cars and bikes he has constructed and inside info from chats with Steve.

How to repair a thread

Damaged and pulled threads can be an annoying inconvenience, especially a stripped spark plug thread. They can also be expensive if the equipment you are working on is vital or difficult to replace. But there are now systems with which you can repair even completely destroyed threads quickly and at a reasonable cost, so saving time and money.

Existing undamaged threads can also be significantly strengthened using these types of repair systems.

Which air compressor?

Selecting the correct air compressor for a particular job should be a relatively painless exercise. The right choice will provide you with a useful machine that can last for many years, provided you maintain it well.

But far too often, choosing a compressor can come down to a random weighing-up of price, cosmetic appearance, or misinformation about the compressor’s specification. In fact, the most important thing to consider is the air consumption of any tool to be used with the compressor.

The saying, “You wouldn’t buy a Mini to tow a boat,” holds true. If the compressor is too small for the job, either the tool won’t work or the tool will work below an acceptable level

Video of a restored 1910 Atlas power hammer

One of our favourite sheddies here at the magazine is Rudi Buchanan Strewe whose engineering shed we featured in issue 102. When we visited Rudi, he was restoring a 1910 Atlas power hammer. Here it is, restored, and up and running as good as new.

Milling Part 3, cutting, clogging, and cleaning

Once your component is securely clamped (see “Showing restraint” Part 2, www.the-shed.nz), ensure the cutting tool is held correctly in its chuck or collet holder, keeping tool overhang or stick-out to a minimum. Being rigid and stable applies as much to tooling as it does to the workpiece. Drill chucks are NOT designed to take side loads induced by milling and are exclusively for drills. Milling cutters should be held in a collet chuck or other suitable holder.

The Shed November/December 2022 issue 105 on sale now

Legendary panel maker

The unassuming Steve Roberts has been called everything from artist and magician to guru of alloy; he himself is more comfortable with the handle ‘tin basher’

Our cover story this issue is on a legend of metal shaping and motorbikes, Steve Roberts. Steve is one of this country’s most respected and admired craftsmen in these fields, and we made the journey to Whanganui to catch up with him.

His output has been prodigious; his innovations groundbreaking; his production values and eye for detail next level. Incredibly, most of his work has been conjured, beaten, and bent with ‘basic tools’ — an indispensable 1920s lathe, a homebuilt press, and an ancient wheeling machine — from a modest shed he once shared with his family’s horses

No more bad vibrations

Enjoy smooth, flawless performance with the wide range of anti-vibration mounts from Hi-Q Components. Manufactured from rubber and zinc-plated steel, the quality range includes male and female threaded mounts in a variety of metric thread sizes, from M4 to M16. The female and male anti-vibration mount sizes…

Milling – showing restraint

In Part One of this series on the milling machine we put the milling machine in the workshop and had it levelled. Before you use the machine, it is important to check the alignment of the spindle. Then comes understanding the importance of preparing the workpiece. Work to be milled or drilled on the milling machine has to be set up so that it does not move during the job. This is one of the most important things you can do if you don’t want an important component or workpiece to end up as scrap because it moved.

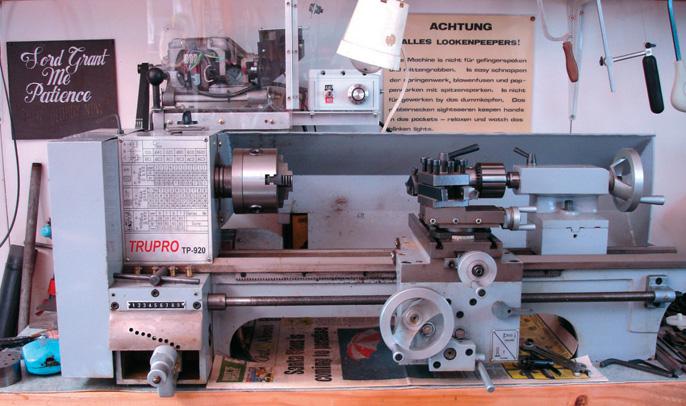

Time for a milling machine?

In a typical home engineering workshop progression, you buy a bench vise, some hand tools, and possibly a bench grinder. After you buy a small pillar drill then comes a big leap — buying a centre lathe.

Along the way you acquire more small tooling, drills, turning tools, etc. You make many useful items and produce a fair bit of scrap.

But then you find the lovely pieces you are turning out on your lathe require other features, especially holes more accurately positioned than you can mark out and drill on your pillar drill. As good as you have become with a file, that flat section needed on the shaft really needs to be machined. And how are you going to make a slot for that keyway?

Create a coffee table

Making an item of furniture does not have to be the daunting task it can seem. If you look closely at commercial pieces, you’ll notice that they share common concepts, and they are simple concepts at that. I’m not suggesting you suddenly choose to give away purchasing furniture and make all your own but making one or two items can become real statement pieces. Perhaps a hall table, or in this case, a small coffee table.

For this project, instead of choosing a basic option of joining a few narrow boards side-by-side to create a solid top, I chose to try a technique I haven’t used before – using wedges of timber to create a radial effect. For your top, you certainly do not have to go this far, and you can choose to have a solid top (these can even be purchased pre-made), or even a solid slab (with or without a natural edge)

Build a portable barbeque

At home, I have a big barbecue in the backyard and a little barbecue upstairs on the balcony that I use when there are just two of us. This hibachi or portable barbecue would be ideal for just two although the grill rack is big enough for four or five steaks or chops and sausages. It can be made with scrap mild steel and a piece of cut pipe. You will find scrap bins at your local engineering works. Most pieces of metal under a metre seem to go in there. You could ask and many companies would be happy to help out, perhaps for a couple of beers.

IoT key driver to growth and leadership opportunities in key industries

A new global survey on the development of the Internet of Things (IoT) across a wide range of industries has revealed some interesting new trends, including a surge in willingness to use AI in some form, increasing concern about connectivity options, and a willingness to establish partnerships to accelerate the delivery of new IoT solutions.

The Global IoT Survey 2022 was conducted by element14,an Avnet company that specialises in the global distribution of electronic components, products, and solutions — and analysed 2263 qualified responses received between January and March 2022 with the aim of gaining a better understanding of technologies, challenges, and opportunities faced by designers and system integrators of IoT solutions.

Welding with LPG

Long before MIG welders or fancy plasmas came onto the scene, the art of welding, cutting, and brazing was to work with gas. The hire or exchange cylinders used by sheddies invariably were oxy/acetylene as this was one of the most common processes for welding, cutting, or brazing.

But there is an alternative–liquefied petroleum gas (LPG) and oxygen. This combination can be used for heating, bending, brazing, soldering, silver soldering, and flame gouging to name just a few applications.

The Shed September/October 2022 issue 104 on sale now

The September/October 2022 issue of The Shed, No. 104, has something in it for every sheddie.

Our cover story this issue is on a couple of blokes who are collectors and restorers of stationary engines of all different types and sizes. Tom Gregory and Gary Norton have got the bug bad and both find it hard to go past a stationary engine of any era and any fuel type. Spending time with Tom and Gary as they describe their addiction to these soldiers of past years will surely convert many readers to the joys of stationary engine ownership.

“There is something endearing, almost comical, about the chugging, spinning, and belching machinations of vintage stationary engines.

Spinning wheel

While we are rather spoilt these days for ready sources of energy, it was once a matter of harvesting what was available in the local environment. More often than not, what was available was a stream or river, and so the workshop was built on the riverbank and the harvesting was achieved by a water wheel.

I’ve always been rather taken by the concept of water wheels (and other mechanical devices that harvest energy from nature), and have been intending to make a small one of my own, even if it was just to be a garden ornamental feature.

As tough as steel

The chemistry of steel determines why and how it should be tempered.

The potential hardness of a steel is determined by its carbon content. Adding small amounts of other elements to the mix can produce enormous improvements in strength, toughness, and

resistance to rust and the response of the steel to heat treatment.

Steels referred to as alloy steels have additional elements such as chromium, nickel, vanadium,

cobalt, manganese, molybdenum, silicon, and tungsten included.

Build a grandfather clock case

I had always wanted to build a grandfather clock case and was given the incentive when a client gave me the a modern clock mechanism and a photocopy of a reproduction of an English Tall Case clock to follow. I had to increase the plan dimensions to fit the mechanism, ash wood was chosen and I ended up with 23 metres of approximately 200 x 25mm rough-sawn at an average length of 2.4 metres costing just under $300.

This is not the ideal style of clock case for anything other than an antique clock mechanism. In modern clock mechanisms, the pendulum swing (which should always be tested) needs a straight-waisted trunk style of clock. However, this project has been done to the requirements.

element14 – your global technology leader

Future proof your business and make sure you are ready and fully equipped for all the challenges of tomorrow with global technology leader element14.

Specialising in high service distribution of technology products and solutions for electronic system design, production, maintenance, and repair, element14 draws on years of experience to support its broad customer base. Offering a tailor-made pathway to a range of services and products for everyone from hobbyists to engineers, maintenance engineers, and buyers, it has a track record of working with both leading brands and start-ups to develop new products.

Unpublished photos from our visit to the home shed of Stan the Builder

With the Pacific Ocean rolling to shore just across the road from his shed at Wainui Beach, avid surfer and passionate sheddie, Stan Scott, is never too far from his two favourite places.

As far as careers in the building trades go Stan’s has been one out of the box, driven largely by his insatiable curiosity and his never-say-never attitude. Building he says, has taken him places he never dreamed of going. Stan is a familiar face to many Kiwi’s. He has built and presented on a raft of TV renovation shows; is the current brand ambassador for Mitre10 and has even managed a few how-to spreads for us at The Shed.

When he’s not busy planning, building, filming and fronting Mitre10’s web based DIY series’ or giving instore presentations across the country, Stan is home juggling his own building jobs with personal projects and family life.

The Shed July/August 2022 issue 103 on sale now

Our cover article for this issue is on how to do lost wax casting. Lost wax casting is one of those workshop processes that are so very useful for replicating parts or just being creative. In this issue #103 of The Shed, we begin a three-part series showing how to do your own lost wax casting to cast bronze. Our teacher is David Reid and it is his own technique that he has perfected over 50 years of casting and teaching: the David Reid Technique. With only the absolute minimum of tools and products, everyone will be able to cast like a pro after following his step-by-step process.

Also in this issue; Making Japanese panels, make a classic wooden workbench, metal garden structures, model railways and much more.

Assorted nuts

For our purposes, a nut is an internally threaded part which is rotated or screwed onto an externally threaded part such as a screw, bolt or stud. If you can pick it up in your hand and put it onto an externally threaded item and tighten it, it is a nut. There will be some exceptions to this which will become apparent.

The Auckland Blade Show is back for 2022

The Auckland Blade Show is back, bigger and better than ever.

Come along to the Ellerslie Event Centre on the 24th and 25th of September to get your hands on the finest custom blades in the country. With over 30 makers exhibiting, we have hunting knives, kitchen knives, and even swords and axes.

Hexagon head bolt or cheese head screw?

There are so many types and kinds of bolts and screws that when you ask for the one you need, it is best if you understand the characteristics of the particular fastener. Then you can ask exactly for what you want. These characteristics are:

* Head type;

* Size;

* Thread form;

* Tensile strength;

* Finish.

How to steam bend wood

This project to make a stool was developed as a way of introducing students to a number of basic

wood-bending and shaping techniques, whilst also giving experience in several useful applications of the router.

The stool consists of two legs in the form of continuous steam-bent hoops or arches, which are housed into matching radiused slots at either end of a curved seat. The legs are stiffened by the addition of smaller arches that fit between them and the centre underside of the seat. For the purposes of this article, I am going to focus on the steam-bending aspect involving the legs as that is the technique that woodworkers seem the most reluctant to try.

Getting up to speed

As sheddies, we are known to cobble together machines from whatever we have at hand. More often than not these items are less than ideal and a motor of some sort may run at a different speed to what we need. If we are looking to make a spindle moulder, belt sander, garden chipper, wind generator, compressor or similar item then it is likely that some sort of gearing will be necessary to give the right RPM at the business end.

Calculating the sizes of gears, sprockets or pulleys is a relatively simple exercise.

Hi-Q Components has it all tied up

If you’re looking for plastic cable ties and mounts, and cable management components, it’s hard to beat Hi-Q Components’ comprehensive range, which covers just about anything you’ll need for the job in hand.

Its selection of plastic fixings and fastenings includes standard strap-type cable ties, from 75mm x 2.4mm to 1500mm x 9mm; as a bonus, many sizes are available in weather-resistant black nylon for outdoor use. Hi-Q also has specialist ties covered, with stock including HVAC duct straps, heavy duty for hydraulic hoses, releasable, screw mount, marker, push mount, double loop mounting, hanking, and beaded ties. As well as cable ties, Hi-Q offers a great selection of cable tie mounts, such as quick and easy self-adhesive tie mounts, and push and lock clip mounts for through-hole panel mounting.

The Shed May/June 2022 issue 102 on sale now

Forging ahead

There are great sheds, amazing sheds, and incredible sheds, but there are also sheds that you could call the ‘king of sheds’.

One such shed is the workshop of West Auckland’s Rudi Buchanan Strewe. In his shed, Rudi turns his hand to blacksmithing, engineering, tool restoration, building hot rods, sculpturing, and so much more. We had such a great time when we visited Rudi and watched him at work.

“The corrugated-iron shed is a deliberate nod to the past. Stepping inside is like entering an early 1900s blacksmith’s forge: clay floors and open beams, antique technology, vintage hand tools, and the faint smell of burnt coal. It is brand new but feels as if it has always been here. Thirty-eight-year-old Rudi embodies a pioneering spirit of discovery and Number-eight wire ingenuity. Whether it is restoring or repurposing old machinery, maintaining his hot rod and his neighbour’s motorbikes, or creating his one-off art pieces, Rudi is always tinkering.”

Making your own campervan

Converting an ordinary van into a campervan is a project I have been talking about for some time.

As a retired technical teacher, I felt I had the necessary skills, and when a 2005 Kia Pregio van in excellent condition became available I decided to take the plunge.

The van is a 2.7 litre diesel, manual, with 26,000 km on the clock and a cargo space of 2.8 metres x 1.65 metres. My plan was to fit the space with two beds, one on each side. They can be expanded to a full-width bed using the foam backs of the seats supported on shortboards between the sides of the seats.

The Shed March/April 2022 Issue 101, on sale across Australia from today

Entrepreneurial opportunities?

With all the changes to our lives we have been experiencing with the Covid virus, is there a new cottage industry movement underway? Many have lost jobs, started new ventures, or are just keen to work in smaller groups in a safe environment, and the bonus is that with the way technology is advancing at such a great rate these days, new affordable tools are available.

The kitset CNC router we are showcasing in this issue is just such a beast. A hi-tech tool that was once only the domain of large engineering workshops is now available for your shed for a very affordable price.

Create this outdoor table using a chainsaw

This design for a macrocarpa slab table is a general design. There are variations and you could do the legs of the table differently, but the general rule is to keep it simple. My old man used macrocarpa for fence posts years ago and they’re still in good condition.

When I was cross-cutting, it didn’t take much to find out I liked macrocarpa. It has a lovely grain and I like working with softwood. It’s a softwood until it’s been sitting around for a year – that hardens it up.

A mechanic turns to clocks

Ken England has been fixing clocks as a hobby in his Whakatane shed since the 90s.

Repairing a clock is not just a case of pulling it to bits, replacing parts then re-assembling, he tells me. “Everything works in sequence and has to be timed.”

He is a member of the New Zealand Horological Institute but was never a clockmaker by trade. What makes Ken “tick” and has given him the necessary clock-repair skills is the engineering know-how already in his background, a knowledge of how to machine parts, manufacture, and silver-solder.

Beat the price rises!

As a result of print industry pricing pressure for paper, freight, and postage, the cost of your favourite magazine will have to increase for both retail and home-delivered subscriptions with the next issue.

Regretfully, we must pass a small portion of these cost increases on to our loyal readers. However, we would like to offer you the opportunity to take advantage of our existing subscription rates.