For this issue of the magazine, we thought it would be an idea to keep our readers busy and enjoying themselves in their sheds on rainy summer days.

Our main article in this issue, “Six Summer Sheddie Projects”, is about combining the fun of summer days and the annual wind-down with family and friends with the spirit of DIY that drove many of us to a self-sufficiency based around our garage workshops and sheds, and more recently extended into MenzSheds.

Our Kiwi number 8 wire mentality gave us pioneers such as Sir William Hamilton of HamiltonJet and Peter Witehira of Power Beat with his never-go-flat battery.

Now, it’s your turn. We’ve come up with six projects of varying levels of skill, and invite you to have a go at them, or — better yet — put your ‘I can do that’ hat on and improve on them.

The workstation

This was the most complex project and isn’t necessarily for the faint-hearted. It took two guys four months to complete, partly because it changed over that time. It was originally going to be wall mounted with a fold-up desk. However, the weight of the MDF meant that actually mounting it on a wall was going to be a challenge, and coming up with a fixing method that was both sturdy and easy to change should the need to do so arise, proved to be ambitious.

The coffee table

The idea behind this coffee table was for it to double as storage space for children’s books and toys. We considered drawers and even a lift-off tray, but drawers can jam unless proper slides are used — and this increases the cost and skill level required. The timber for the top was too heavy to be lifted and carried around. The screws for the hinges turned out to be the only screws in the whole project, with everything else being glued and biscuit-jointed or glued and dowelled.

The lamp

This was my [writer Nigel Young] project, and I started by going through the timber rack at our MenzShed, looking for different colours and sizes, as the plan was to laminate them together and then have the base and lamp holder turned on a lathe.

I started by cutting a range of pieces into squares, then establishing the centre of each by drawing a line across the diagonals. The intention was to drill through each of them, and then pass a 6mm dowel through them all while also glueing them all together. Before drilling them, however, I used a compass to draw the best circle I could out of each of them. Next, I used a bandsaw to cut out each circle as closely as I could — not one of my strengths but I got them pretty close.

The painter’s easel

We had been thinking about this one as a potential stand-alone how-to article for The Shed in its own right, after seeing the size of them in an art store — all very nice, but where do you keep them as they can take up quite a lot of space. So, the main criterion for this was to be able to use it and then fold it away with minimal storage requirements.

The bunk and desk

This project was a similar size to the workstation, the difference being that the employee who used that was able to walk away from it at the end of the day. With the bunk desk, however, the user was required to sleep at their station — no sneaking off for a life somewhere else.

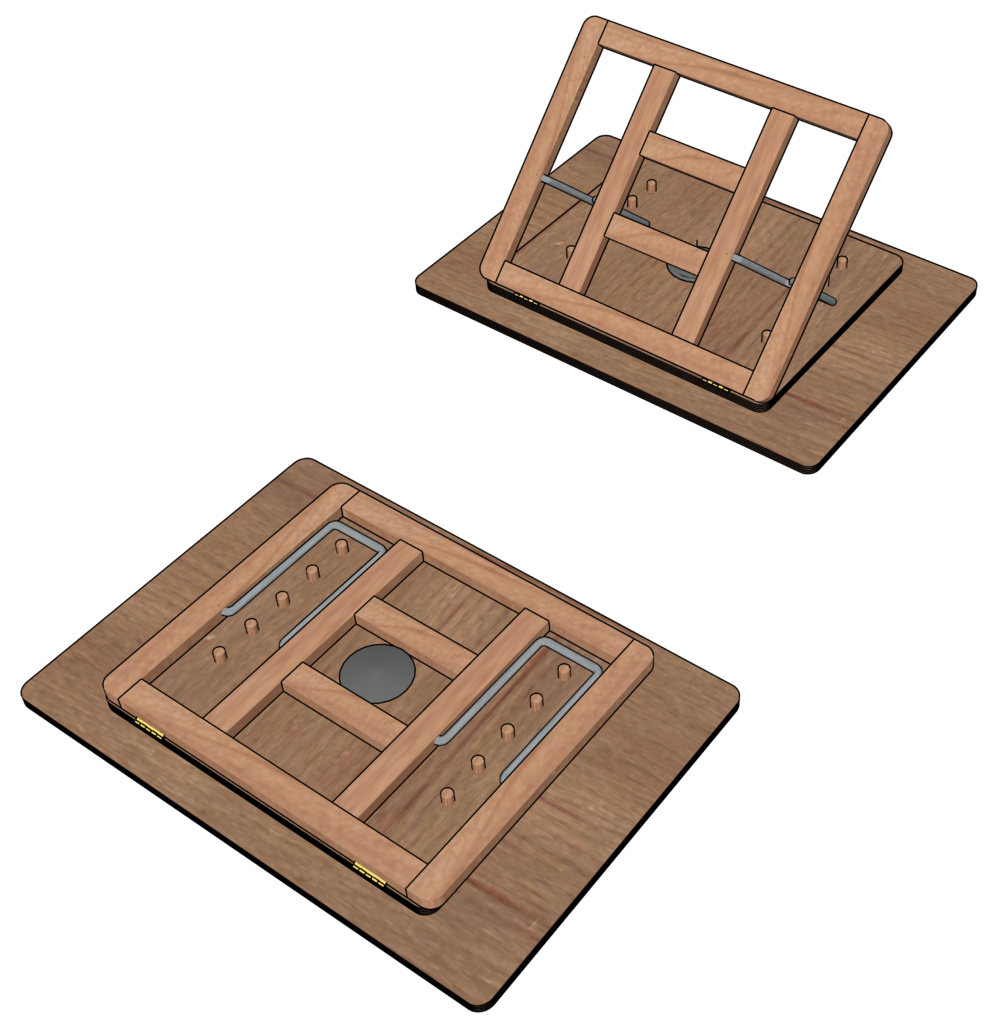

Tablet holder

This was built by a sheddie who had retired from the world of IT, and who had the analytical tools to sit down and write himself a brief. The tablet holder needed to be able to rotate as well as be raised up and down, so he started with some questions and observations:

Why would one want a tablet holder that needed to be able to rotate as well as be raised up and down …

Build a small trailer, part two

At the end of part one (The Shed, November–December 2022, issue 105), we sent the welded frame, the front and back gates, and the axle of our trailer for galvanising. You could paint the trailer instead of galvanising it, but paint won’t get deep inside the box section to stop rusting in there. You can paint the frame after galvanising, but there’s a lot of fuss with primer and preparation.

My shed — Murray Brown

It has been said that the first law of intelligent tinkering is to save all the parts. That is exactly what Cambridge sheddie, Murray Brown, has been doing since he was a nipper. Murray is a mechanical engineer, wood turner, and self-confessed hoarder. When I arrive to check out his growing fleet of home-built tractor models made from upcycled sewing machines, I somehow lose an hour just nosing around the first two sheds of his eight-shed property.

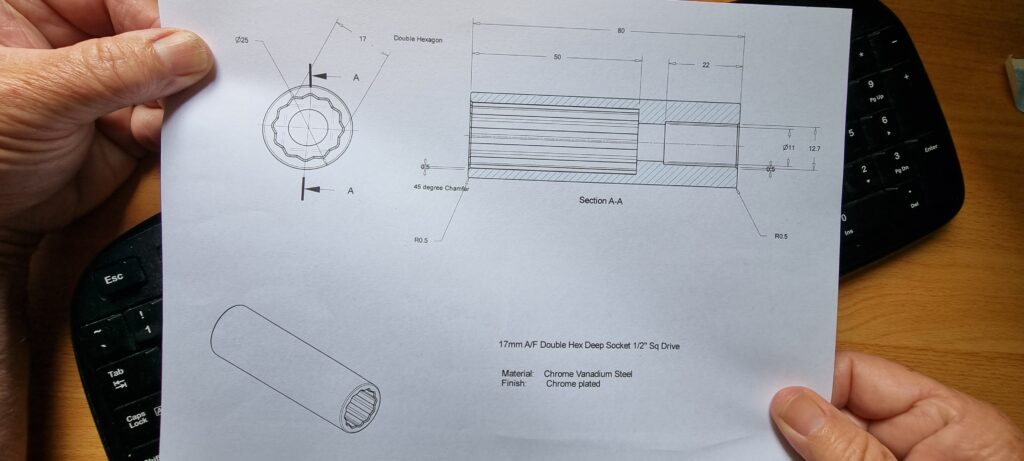

Alibre 101, part three

This issue contains part three in our series about using 3D design software and the Alibre Atom 3D software, in particular.

In the previous articles, we have created a 17mm A/F half-inch drive deep socket and then changed it slightly to create a socket that’s the same, but with double hex instead of single. This time we are going to make a 2D conventional drawing of the socket. This is very easy. By accessing the file of the part you have created, most of the work is already done.

Hard copy drawings are still useful when you need to convey what you want to have made, particularly when CNC machinery will not be used. The details of a part you have created can be sent by email as a 2D drawing directly from Alibre, just as a 3D digital file of the part can be.

Build a kitset aircraft

I still get a kick out of seeing the expression on people’s faces when I tell them I’m building a plane in my shed. What, a real plane, is a common response, or, are you a pilot? Yes, I am, but more about that later. I think many people’s first thought when they hear the term homebuilt or, more correctly, amateur-built aircraft is that it’s made of balsa wood, spit, and number 8 wire.

However, my project is a two-seat computer-designed Vans RV-14A mostly aluminium aircraft, powered by a 210hp Lycoming engine. It comes as a kit made by Vans Aircraft in the USA, and it has all the necessary parts and hardware except the engine, propeller, and instruments.

Build a kitset log house, part three

We’re onto the finishing bits, which include electrical, plumbing, cladding, bathrooms, and kitchen, plus all the fiddly bits to try and make it look good. For that first winter, we all moved from the partially finished master bedroom and en suite into the — not really finished — kitchen/lounge/dining to have one warm room with the fireplace for the new baby — nice to have extra space, as well. Meanwhile, I turned the master bedroom into a workshop again so I could completely finish it and the en suite bathroom.

This was time-consuming as there were many fiddly bits to complete …

Off the grid — spinning, spinning, spinning

Off-gridders are acutely energy aware. They have to be; they realise very quickly that what they don’t demand, doesn’t have to be generated. It is no coincidence, then, that hand-tools are much discussed, coveted, refurbished, and, indeed, loved. One tool that ticks all those boxes hereabouts is the spinning wheel. My partner will often sit treadling one of our workhorse Ashfords, as we have our cuppa and discussions at each end of the day; she says it’s therapeutic. I just love the way spinning wheels do exactly what they have to do, perfectly, as is so often the way with tools designed when energy was scarce.

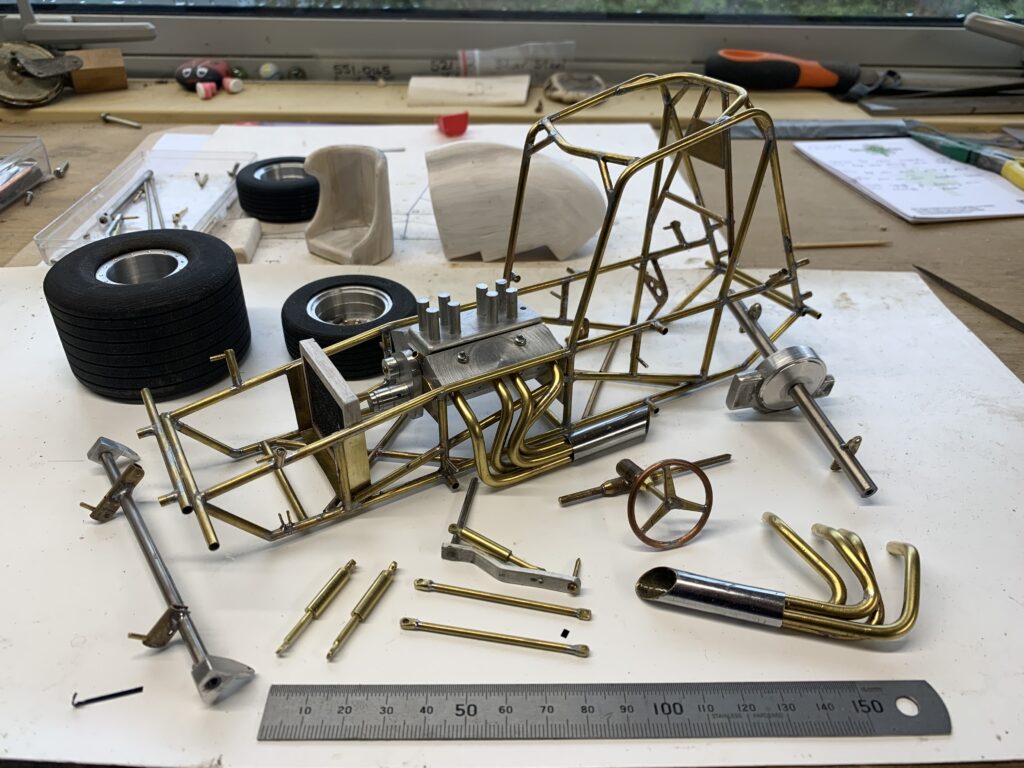

Automata in miniature

The man’s arms move up and down, hammering out a tune on his piano. He is accompanied by a woman, sawing away at a fiddle, while a man in green with a fedora hat sits strumming a banjo. These wooden figures are brought to life by the turn of a handle. The whole band would fit in a shoebox. It is a delightful thing, a mesmerising, sort of alive, thing.

“It’s not so much the band that appeals to me,” says creator Ian Roberts. “It’s the mechanical part of the thing — getting it all to go, with hands and levers and things.”

The Shed shrink — a new kind of saviour

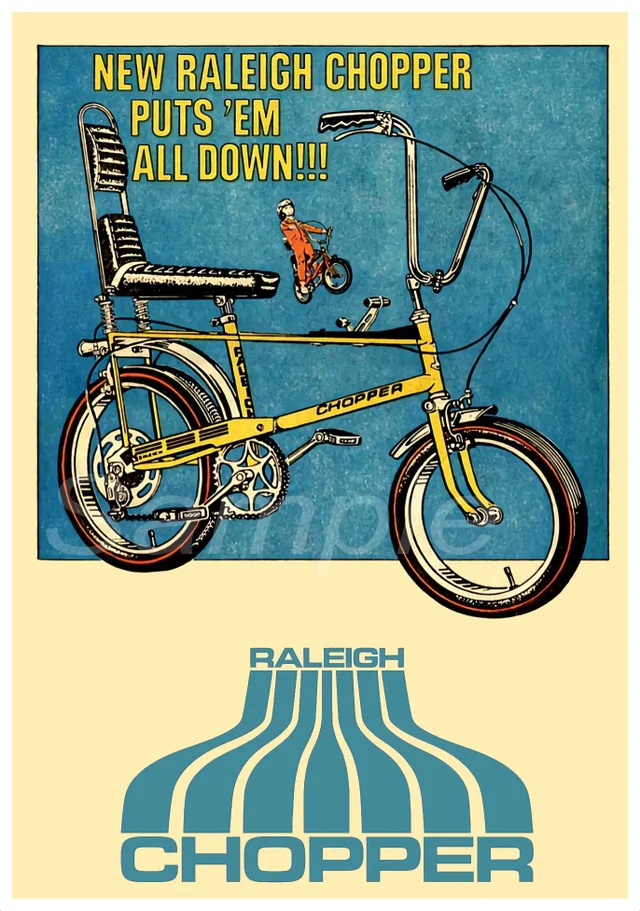

Queen wrote several songs about them; Jesse James was inspired by riding them, and began West Coast Choppers; some people wear a yellow jersey whilst riding one in front of millions of viewers; others ride one that has only one wheel; they come in a variety of shapes, sizes, and colours, and are priced accordingly. Let’s talk bicycles.

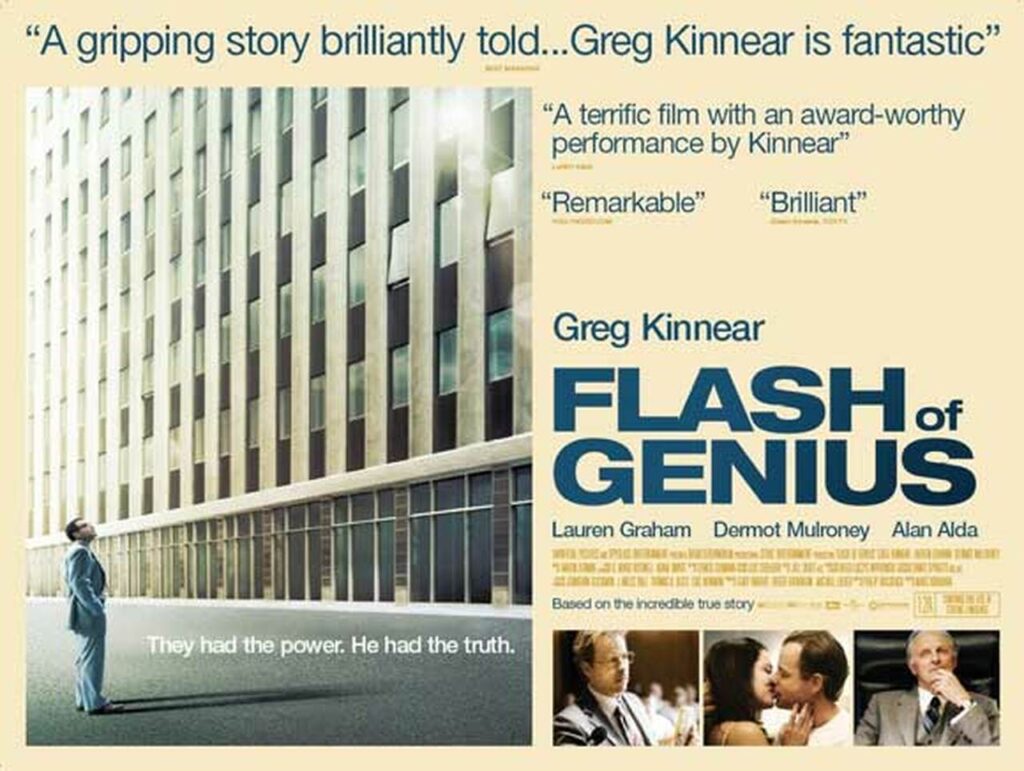

Patent that invention

You’ve laboured long in the shed or had a supernova of inspiration, and have come up with a widget that is going to make your fortune. It is innovative, transformational and, best of all, highly desirable.

Now comes the difficult part. You are naturally reluctant to reveal any details to anyone, being understandably fearful that your invention will, as so often happens, be stolen. What to do?

Seagull rescue

Harley Lishman has been collecting Seagulls for less than a year but is already hooked. He says, “I love the retro lines; crude and simple, but reliable, and you can fully strip, rebuild, and get them going in less than a week. With cars, it can take 10 years to get to the same point.”

The walls, boxes, and shelves of Harley’s ‘man cave’ boast close to 20 Seagulls in various states of repair plus a couple of space-age beauties, a ’38 Bendix Eclipse and a ’47 Mercury, which he aims to revive in the future. His restorations do not stop there; his collection of vintage motors includes a couple of reel mowers, 1930s rotary hoes, and a burgeoning stockpile of stationary engines.

Back o’ The Shed by Jude Woodside

I have a couple of young relatives who are just discovering the joys of home ownership and renovation. Consequently, my tools are in demand. I don’t mind except when I go to find a tool only to realise I loaned it out weeks ago and I can’t remember who to. So I thought I would give these beginners a list of tools that will serve them well long past their last renovation.

Thinking about this, I remembered when I first started doing the same thing, at about the same age, and the lessons I learnt back then. The most important of which was: don’t buy cheap tools. It is worth remembering the aphorism: ‘The bitterness of poor quality remains long after the sweetness of low price is forgotten’. Ask me how l know.

So I have compiled a list of tools that I think are essential for anyone embarking on home renovation — tools that will last a lifetime, and more than return the investment.

Head to our online store to purchase a copy of this magazine.