Videos of metal shaping and motorbike guru, Steve Roberts

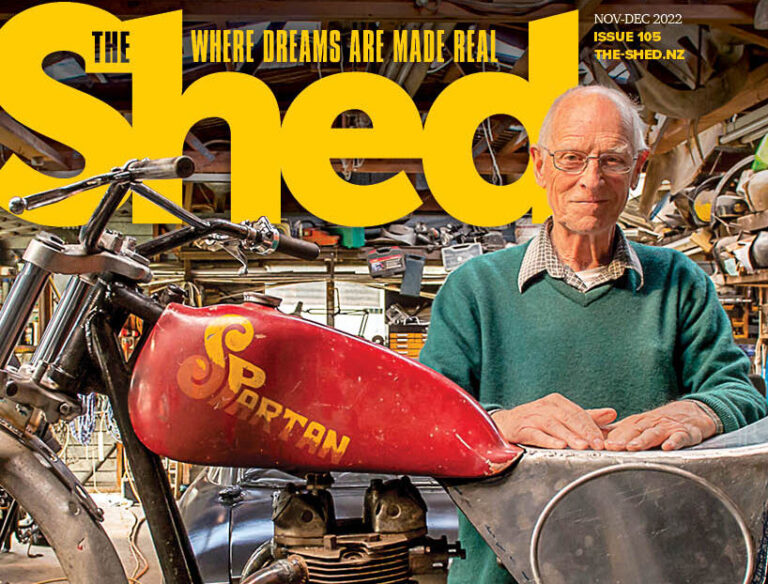

In the November/December issue 105 of The Shed, our cover story is on a Kiwi legend of metal shaping and motorbikes, Steve Roberts.

If you enjoyed that article here is a link to a website that has even more of Steve’s story as well as videos of the cars and bikes he has constructed and inside info from chats with Steve.