The advantages of Peanut Furniture Connectors

In the world of furniture manufacturing, every detail matters. A new product revolutionising cabinet and furniture construction is the Peanut Connector. Available from Jacks, these unassuming yet highly effective furniture connectors are set to become an essential tool in the arsenal of modern cabinetmakers. Peanut connectors offer a host of advantages that speed up and simplify the assembly process, reduce material costs, improve the overall quality of cabinetry, and deliver a more contemporary slim-line look. Let’s explore these connectors and the numerous benefits they bring to the table.

What are Peanut Connectors?

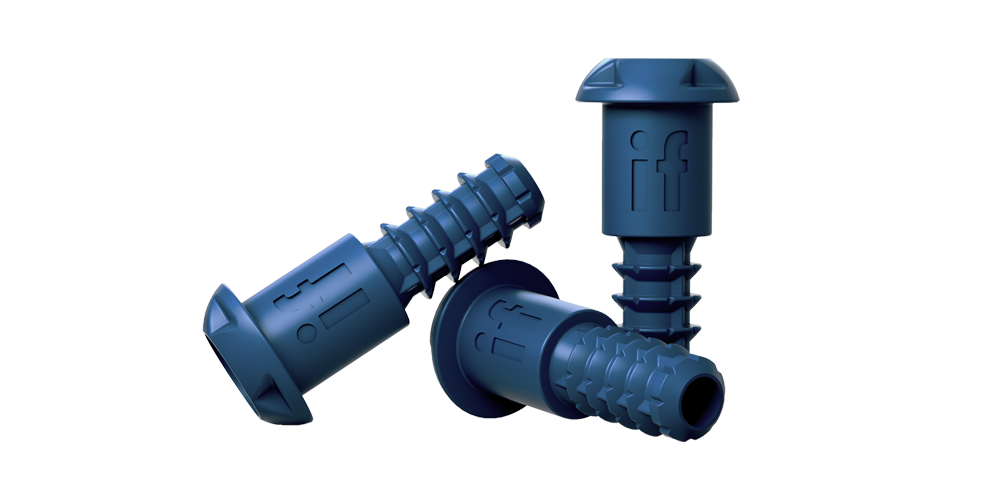

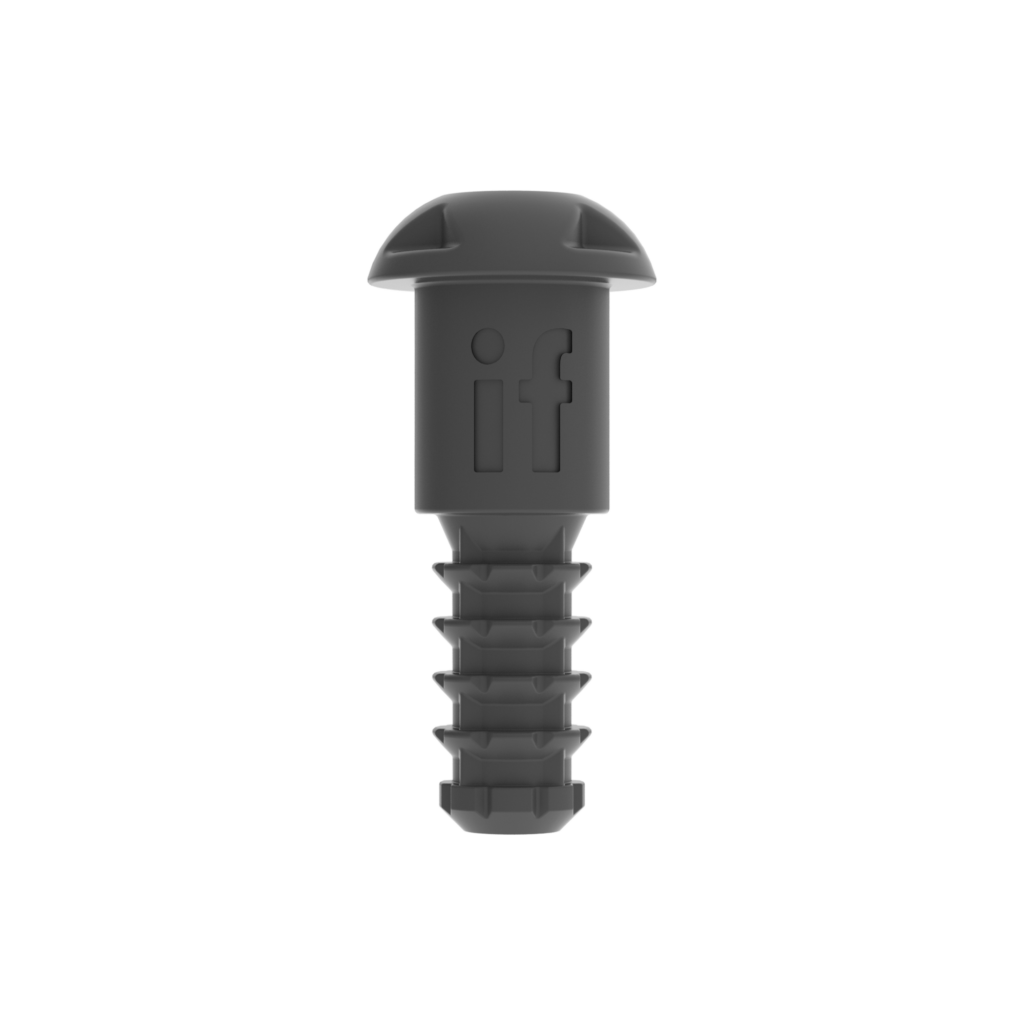

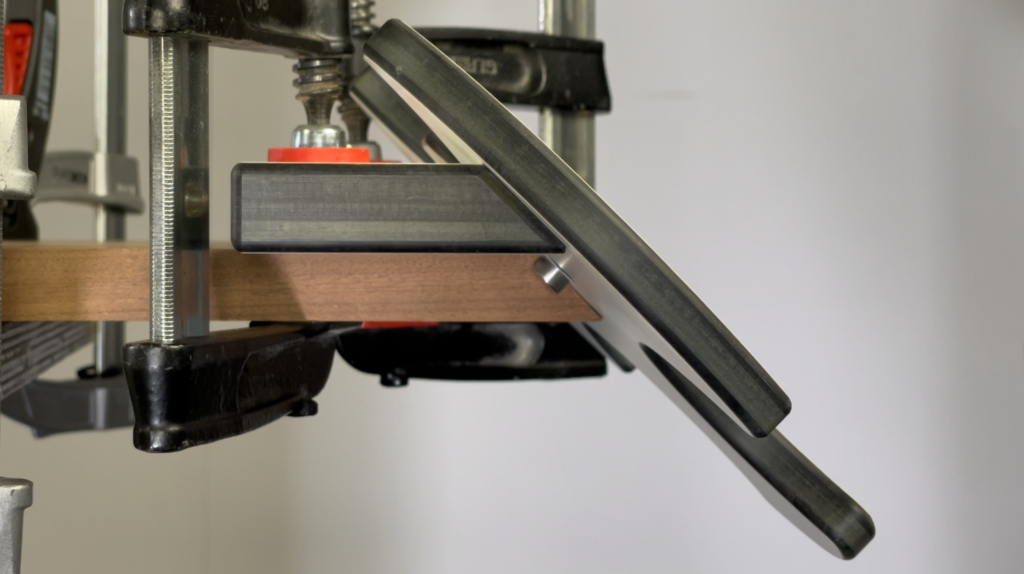

Peanut Connectors are small one-piece, dome-headed fasteners with a toothed barb. The toothed barb is inserted into part A, while the head of the peanut locates into a pre-milled keyhole slot in part B.

As parts A and B slide together, the combined profile of the domed head and keyhole slot cause the two parts to self-clamp from the inside creating an extremely strong connection. Their simplistic yet ingenious design allows for fast and efficient assembly while delivering super-strong constructed furniture and cabinetry.

Advantages of Peanut Cabinet Connectors:

- Easy assembly: One of the most significant advantages of Peanut Furniture Connectors is their ease of use. Unlike traditional methods that rely on screws, cams, or adhesives, Peanut Connectors require minimal skill and tools to align and join components together. This simplicity not only speeds up the assembly process but also reduces the skill level required and potential for errors, making them ideal for all furniture and cabinetmakers.

- Strong and reliable: Peanut Connectors are engineered to provide a strong and dependable connection. Their unique design ensures that components stay firmly in place, reducing the risk of loosening over time. This structural integrity enhances the longevity and durability of furniture and cabinets, ensuring they withstand the test of time.

- Aesthetic appeal: The discreet nature of Peanut Connectors offers a cleaner and more aesthetically pleasing look compared to visible screws and cams. This streamlined appearance is particularly advantageous for cabinets with a modern minimalist design, where clean lines and unobtrusive hardware are highly valued.

- Disassembly and reassembly: In the event that it’s better for furniture and cabinets to be flat-packed for easier and more cost-effective delivery, components can be quickly disassembled in the workshop and reassembled again on site.

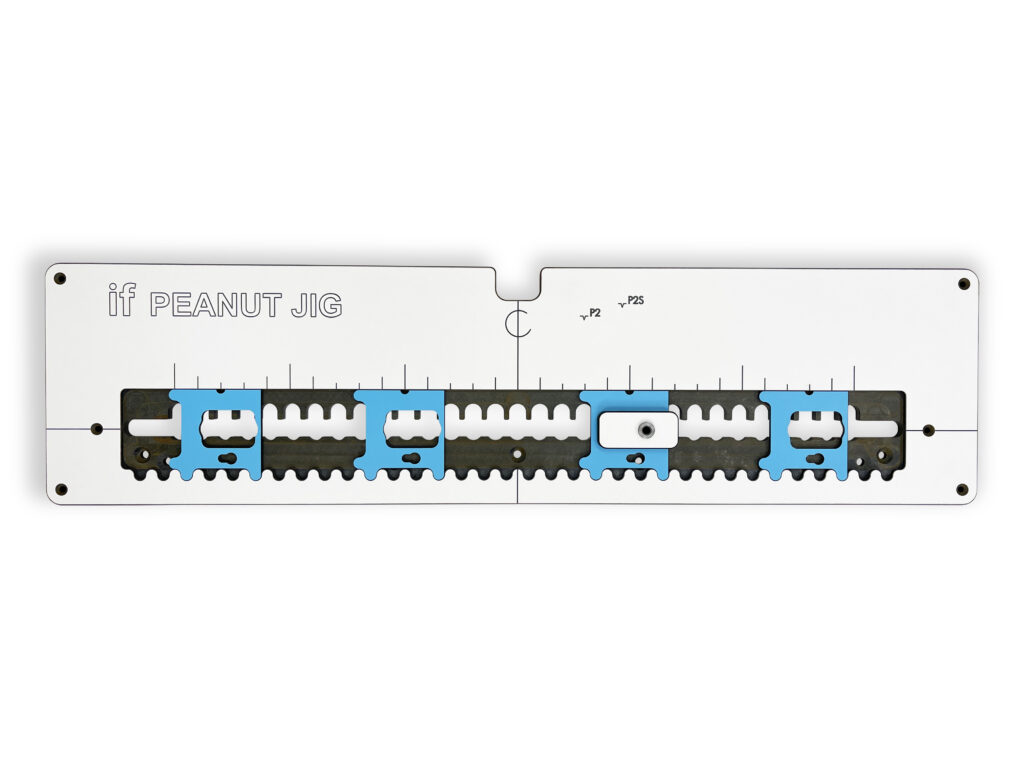

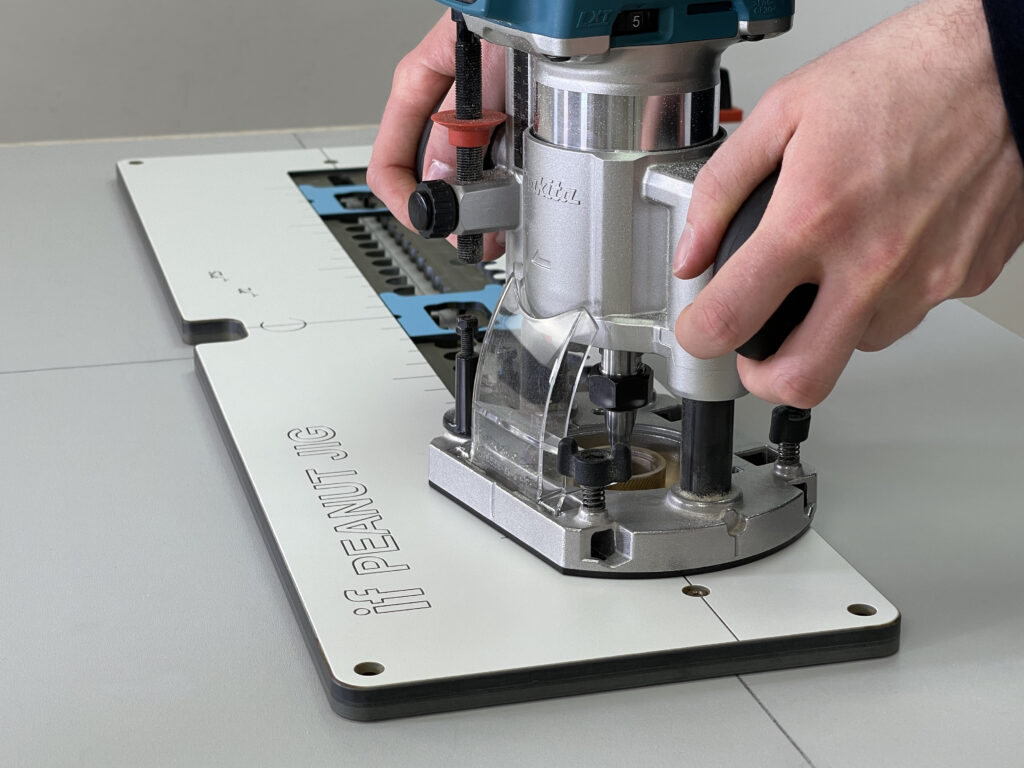

- Cost-efficiency: Peanut Connectors are cost-effective as they are a small yet ingenious one-piece connector. All that’s needed to get started is a plunge router, Peanut jig and Peanuts.

In conclusion:

Peanut Furniture Connectors are an ingenious and invaluable addition to the world of cabinet and furniture construction. Their ease of use, structural integrity, aesthetic appeal, and cost-efficiency make them a go-to choice for all woodworkers, from DIYers to professionals, looking to simplify the assembly process and enhance the quality of their products.

Peanut connectors are available now from Jacks

Peanut 2s are completely hidden connectors and recommended for use in solid timber.

Peanut 3s are completely hidden connectors and recommended for use in cabinetry.

For more information on Peanut Connectors, call Jacks on 0800 522 577, or email [email protected].