Porcelain drilling solutions using Tusk VB core bits

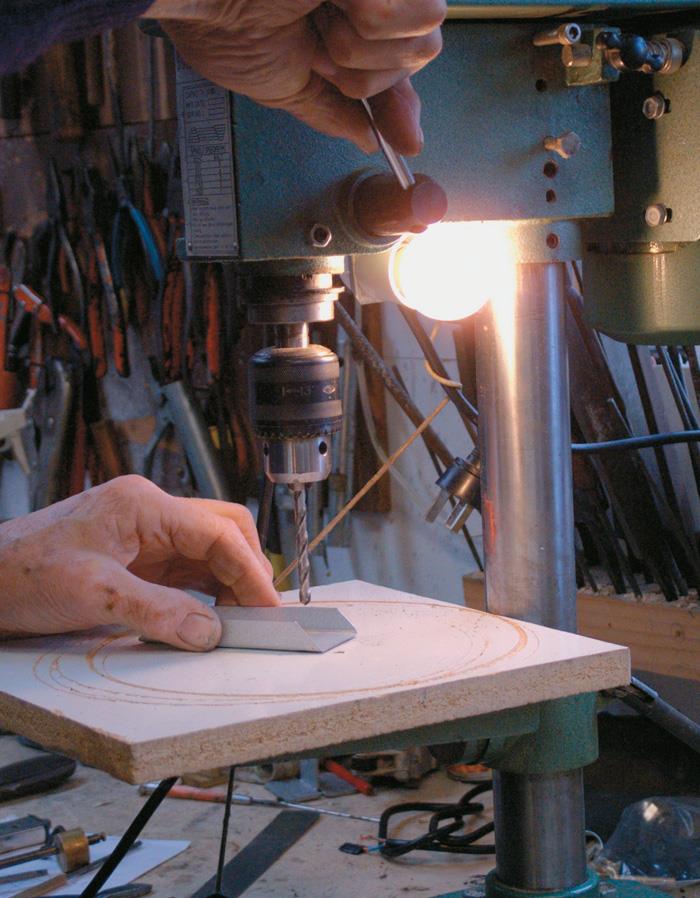

Watch this video and be impressed at what these core bits can do

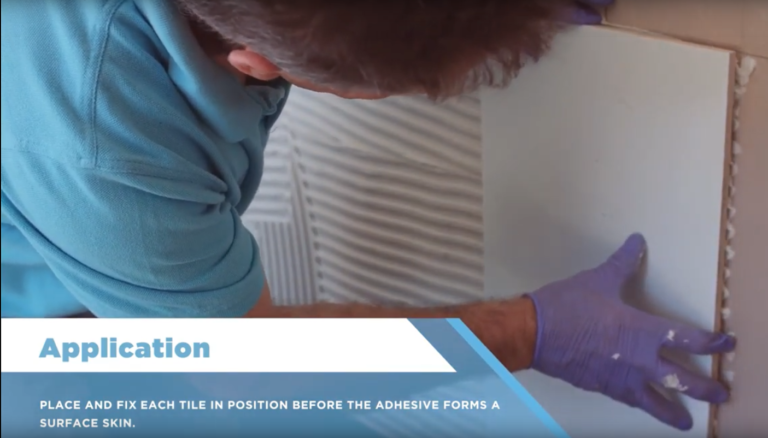

The drills have a vacuum-braised diamond cutting edges for longer life and strength. The range of Tusk VB core bits are for drilling, grinding and cutting using angle grinders for precision and control.