On fire!

Over the last couple of decades I have made my share of braziers, fire pits, and pizza ovens out of anything from old truck rims to LPG cylinders. But my hands-down favourite for source material for fire containers is CNG cylinders.

Over the last couple of decades I have made my share of braziers, fire pits, and pizza ovens out of anything from old truck rims to LPG cylinders. But my hands-down favourite for source material for fire containers is CNG cylinders.

Making a violin is a complex job involving around 40 pieces of wood of various types and sizes and plenty of patient, skilled woodworking. In Part One we chose the best maple for the back and spruce for the belly, shaped these plates and created the rib structure. Now it’s time to finish the construction.

When I decided to make a violin to take to a conference in America, I chose a beautiful example by Guarneri “del Gesu”—the “King” violin made in 1735—as a model.

Given the significance of the violins by the great makers, there is a respected tradition of making copies or instruments modelled on their work. I was quite happy for The Shed magazine to follow its progress but as there are books written in great detail about violin-making, this magazine article can only be a summary of what I did and some of the problems I encountered.

Always wanted your own knife-makers forge? Well in the July/August Issue 85 of The Shed we show you how to make two differing styles, one using LPG power and one using used engine oil to create the heat. What a great way to dispose of old oil and both give great results without incurring huge build costs.

Then we…

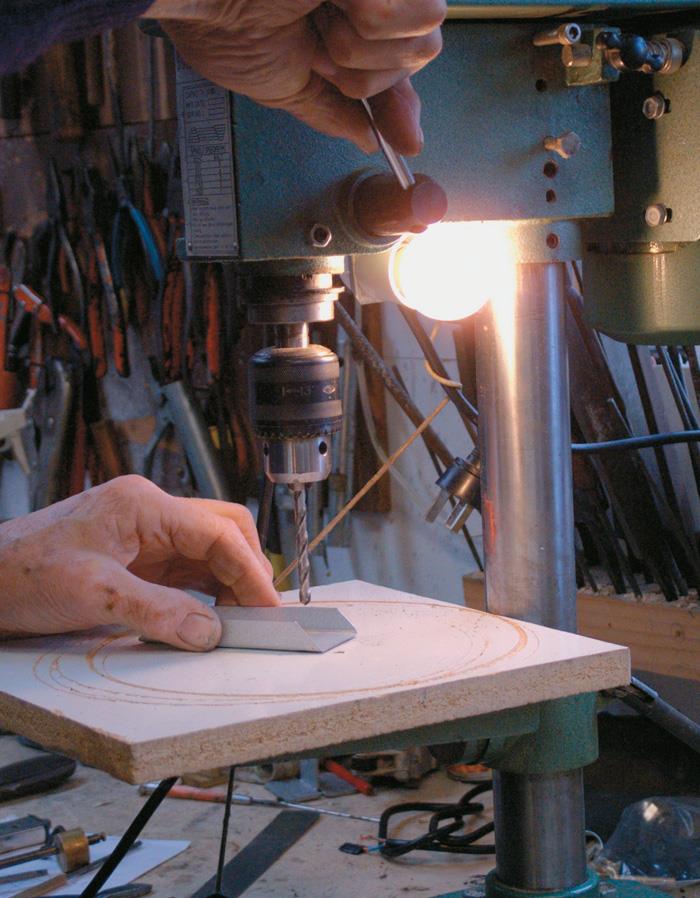

The answer came like a light bulb. In fact, it was a light bulb – one that fits snugly under the top of the drill press and shines on the complete work area below, with little or no chance of casting unwanted shadows. It’s easy to make, as you can see from the step-by-step pictures.

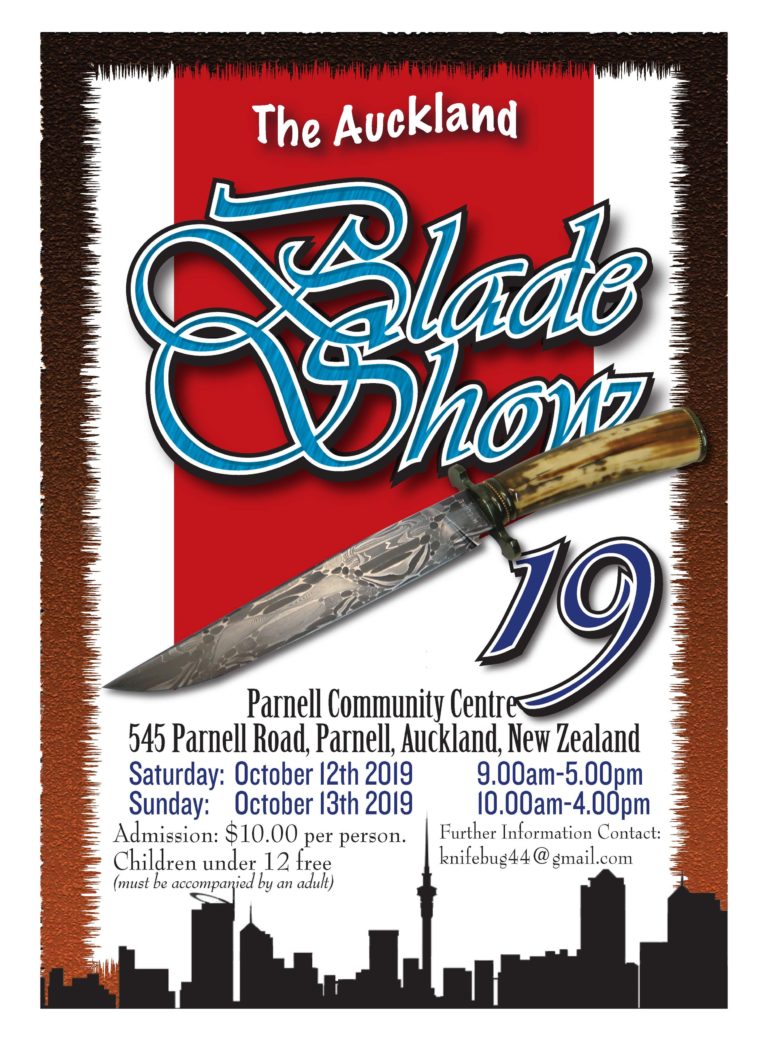

Good news, the Auckland Blade show is back on again this spring. Same location, 545 Parnell Road, Parnell, Auckland and this year it’s on the weekend on 12 & 13 October. See their poster for more info.

The Shed will see you there.

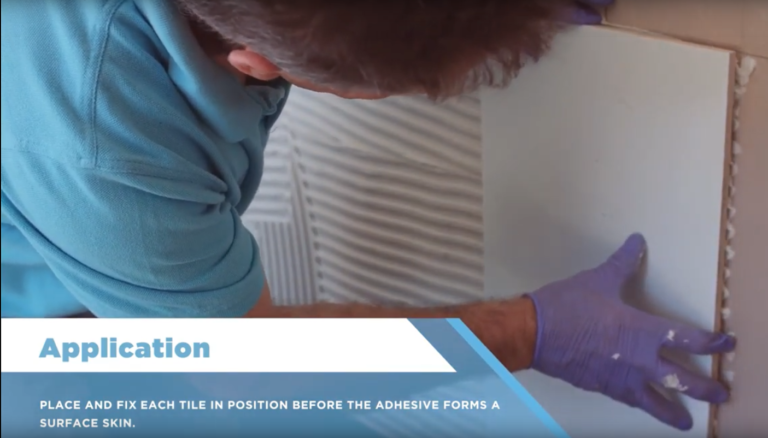

Got some tiling to do? Need some best practice tips?

Well here are three videos from Selleys with advice on fixing tiles to a surface, grouting and finally sealing the tiles.

Its all done using Selleys products so you can be sure of a great result.

Enjoy.

For the centre, I had intended to use one-inch (25.4 mm) diameter stainless steel that I had left over from a previous job but the lamp we purchased came with a one-inch chrome-plated tube which I decided to use. It also came with a screwed insert in the top for attaching the lamp and this saved me from needing to make an insert.

If you use stock tube, you will need to make an insert to fit in the top of the tube to take the lamp you purchase. This could be a nut you can find with the same thread as the lamp and where you just need to have the outside diameter reduced or you can make an insert and thread it accordingly.

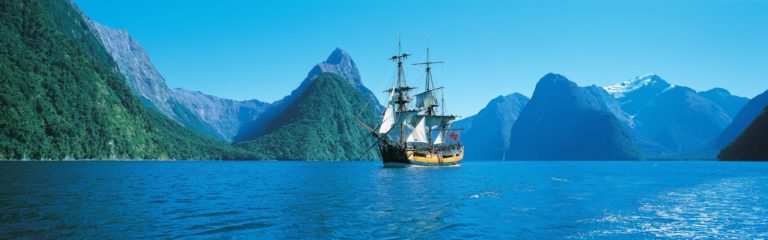

The New Zealand Maritime Museum in Auckland is currently seeking skilled model makers and miniaturists to volunteer in their fully equipped Model Maker’s Workshop.

The museum has embarked on an ambitious project to build a replica model of Captain Cook’s HMS ENDEAVOUR, to commemorate the 250th anniversary since the first onshore meetings between Māori and Europeans.

The museum estimates it will take a team at least 2000 hours to complete the build of the model.

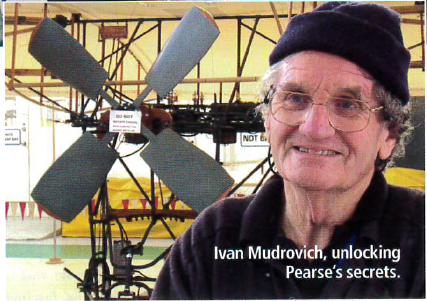

“The sound of that Pearse wing destroying itself in a matter of seconds as it tore itself apart in a chain reaction fashion on the 14th September in 2012 at Whenuapai Air Base is a sound that I don’t think any of us will forget for a long while.” Retired Air New Zealand captain, Neville Hay as test pilot was not apprehensive but noted, “You have to think about everything you do. You can’t rely on memory of flying the plane.”

The particular process we are looking at in this article does not effectively alter the dimensions of the part as it etches into the surface rather than deposits on top. Black oxide finish is sometimes called parkerizing and it is common on components such as gun barrels because it does not involve high enough temperatures to cause distortion and there is no dimensional change.

In the May/June 2019 Issue 84 of The Shed we share the amazing skills on one Daniel Strekier who built himself his own extraordinary bicycle… almost entirely out of wood!

It really is something to behold and you just have to sit back and admire the skills that went into making this incredible piece of usable art.

Jude Woodside sits down with Brent Sandow and gets all the background on this, NZ’s most accomplished knifemaker, who shares his inspirations and skills with us.

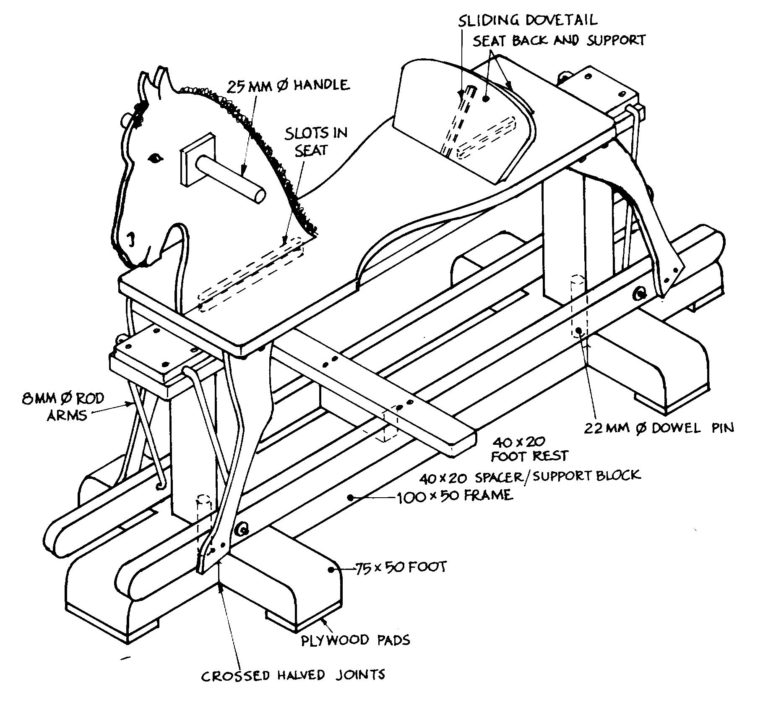

I made the prototype of this rocking horse more than 15 years ago not having the recipient present to measure against I approximated the sizes. It was a good fit…for me, but sadly not for a potential junior jockey. The next model I attempted was suitably scaled to a more appropriate size and with a few refinements is presented here

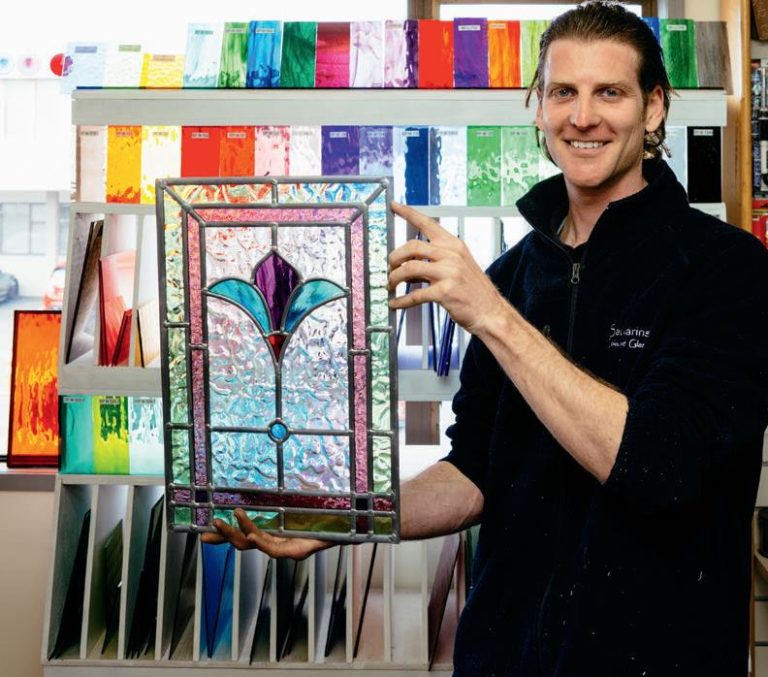

Chance is a fine thing. When Myke Bakker’s mother decided to do a leadlight course when he was a high school student and brought the tools home, she unwittingly set on course a chain of events that would influence the direction of her son’s life.

“I was fascinated by the whole process and started mucking around,” says Myke. “I made my first leadlight when I was 17.”

Fourteen years later, Myke is still intrigued by the many possibilities of working with glass and he’s made a career out of it in the process. He is one of a small team who work at Sauvarins Coloured Glass Studio in Auckland’s Penrose specialising in all things glass.

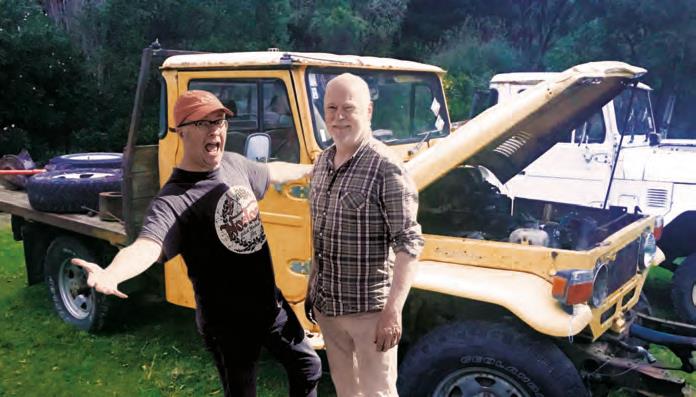

Start me up is the world’s first car show based on the phenomenon of “cold starting” – an online craze where cars that haven’t run for years or more – typically decades have their engines fired up or “cold stated”.

Screening now on TVNZ On Demand and soon on the Duke channel. Click ‘Read more” to get the full rundown on the show.

The Shed magazine is eclectic, informed, and always fascinating. Aimed at those with a few tools and perhaps a few clues: this is the magazine for real sheddies.

Packed with ideas, projects, advice, and peeks into other people’s sheds providing inspiration, ideas, and techniques, or just for the sheer enjoyment of the sheddie’s endless inventiveness, The Shed is the project enthusiast’s bible.

Sign up here to The Shed monthly email newsletter for exclusive reader offers.

Sign up here to The Shed monthly email newsletter for exclusive reader offers. For signing up, we’ll send you a free copy of The Shed, just simply put your postal address in the form.