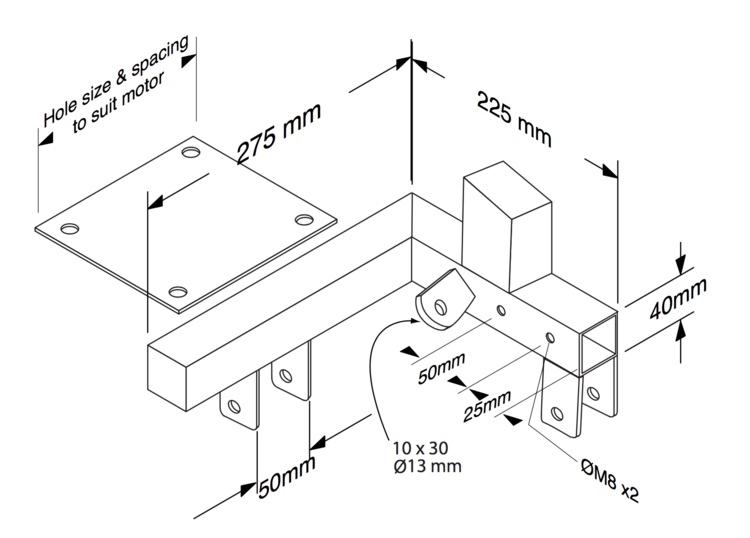

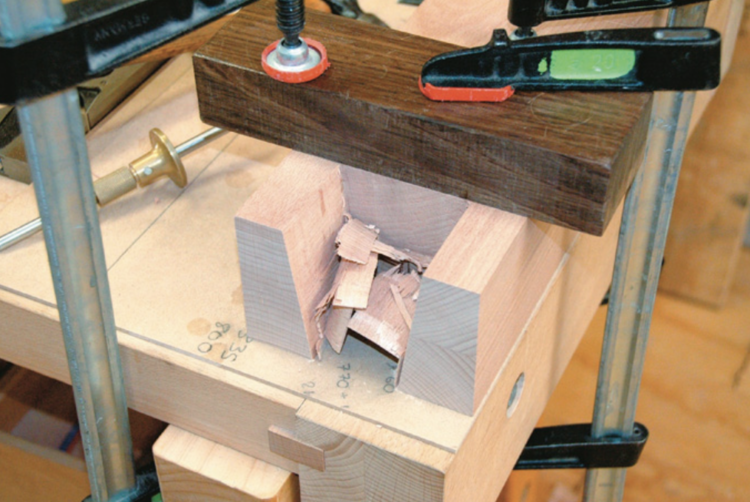

Video of how to make a metal (swarf) sweeper

In Issue 81 of The Shed, Des Thomson showed us how to solve the problem of sweeping up metal waste and nails from your workshop or shed. In this video, Des discusses the build, then displays the sweeper and its uses.