Latest news and features

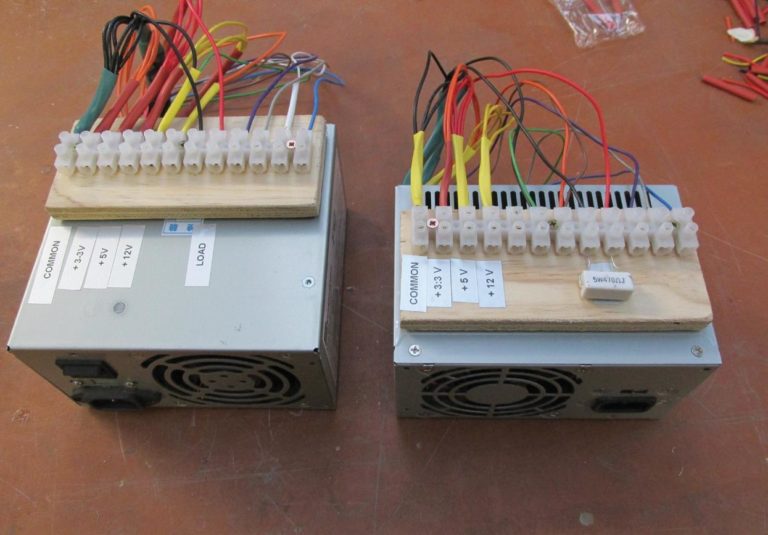

AC/DC: converting simply

There are times when you need DC (Direct Current) voltage for some project or other; it is mostly small applications—has to change the 230v AC mains into something else first, normally a low-voltage DC.

The new issue of The Shed, #85, on sale Australia-wide now

See this link to find your nearest Australian retailer https://www.theshedmag.co.nz/home/2018/9/5/find-your-local-australian-the-shed-retailer or head to https://magstore.nz/ to buy a copy or to subscribe for six months – two years, print and digital versions available.

Lucas Mills celebrates 25 years of portable milling

Australia’s Lucas Mill celebrated its 25th year in the business of making portable sawmills. More than 18,500 Lucas Mill portable sawmills have been sold into more than 100 different countries, and the company says its first portable swing blade sawmill is still operating.

On fire!

Over the last couple of decades I have made my share of braziers, fire pits, and pizza ovens out of anything from old truck rims to LPG cylinders. But my hands-down favourite for source material for fire containers is CNG cylinders.

Making a violin – part two

Making a violin is a complex job involving around 40 pieces of wood of various types and sizes and plenty of patient, skilled woodworking. In Part One we chose the best maple for the back and spruce for the belly, shaped these plates and created the rib structure. Now it’s time to finish the construction.

Generators: Let the power be with you

As winter approaches and power outages become something of a given, we thought it might be useful to identify what you need to know about generators, safety, their uses, and how to connect them to your home.

A generator is a motor driving an alternator to produce power, and with the advent of these Inverter Generators (see my review of Honda inverter generators) the basics haven’t changed, but how they operate has.

Making a violin – Part One

When I decided to make a violin to take to a conference in America, I chose a beautiful example by Guarneri “del Gesu”—the “King” violin made in 1735—as a model.

Given the significance of the violins by the great makers, there is a respected tradition of making copies or instruments modelled on their work. I was quite happy for The Shed magazine to follow its progress but as there are books written in great detail about violin-making, this magazine article can only be a summary of what I did and some of the problems I encountered.

No one regrets buying quality – The Shed product spotlight

Honda’s inverter generators are famous for their reliability, fuel efficiency and portability but they also supply ‘clean’ power for phones, laptops and power tools. Older generators can produce power spikes or variable voltages that can damage modern appliances. The portable EU10i was the first generator of its size to feature a sine wave inverter assuring commercial-quality electricity.

The Shed July/August 2019, Issue no 85, on sale now

Always wanted your own knife-makers forge? Well in the July/August Issue 85 of The Shed we show you how to make two differing styles, one using LPG power and one using used engine oil to create the heat. What a great way to dispose of old oil and both give great results without incurring huge build costs.

Then we…

Porcelain drilling solutions using Tusk VB core bits

Watch this video and be impressed at what these core bits can do

The drills have a vacuum-braised diamond cutting edges for longer life and strength. The range of Tusk VB core bits are for drilling, grinding and cutting using angle grinders for precision and control.

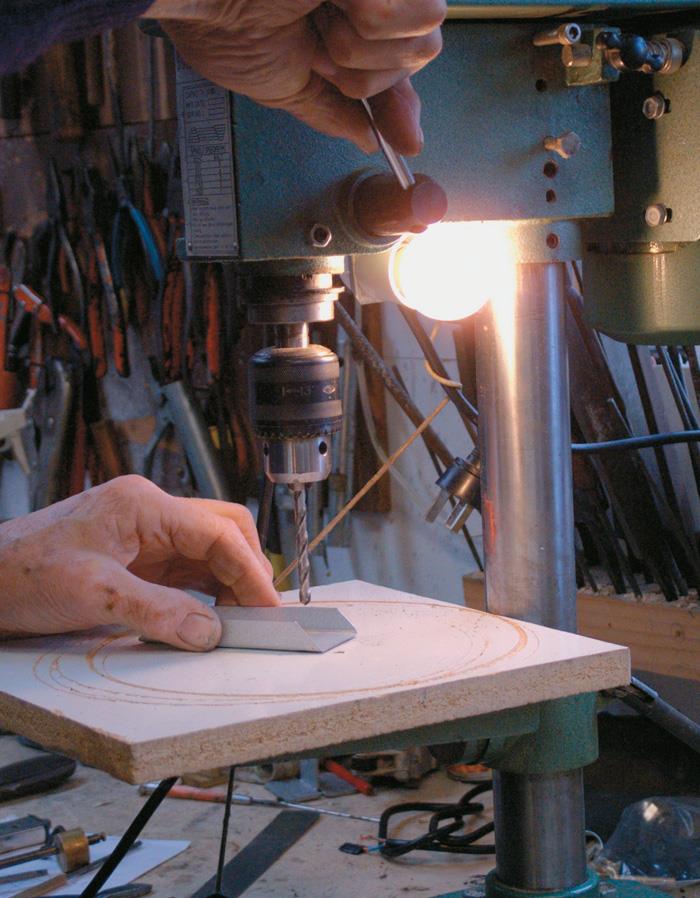

A bit of light work

The answer came like a light bulb. In fact, it was a light bulb – one that fits snugly under the top of the drill press and shines on the complete work area below, with little or no chance of casting unwanted shadows. It’s easy to make, as you can see from the step-by-step pictures.

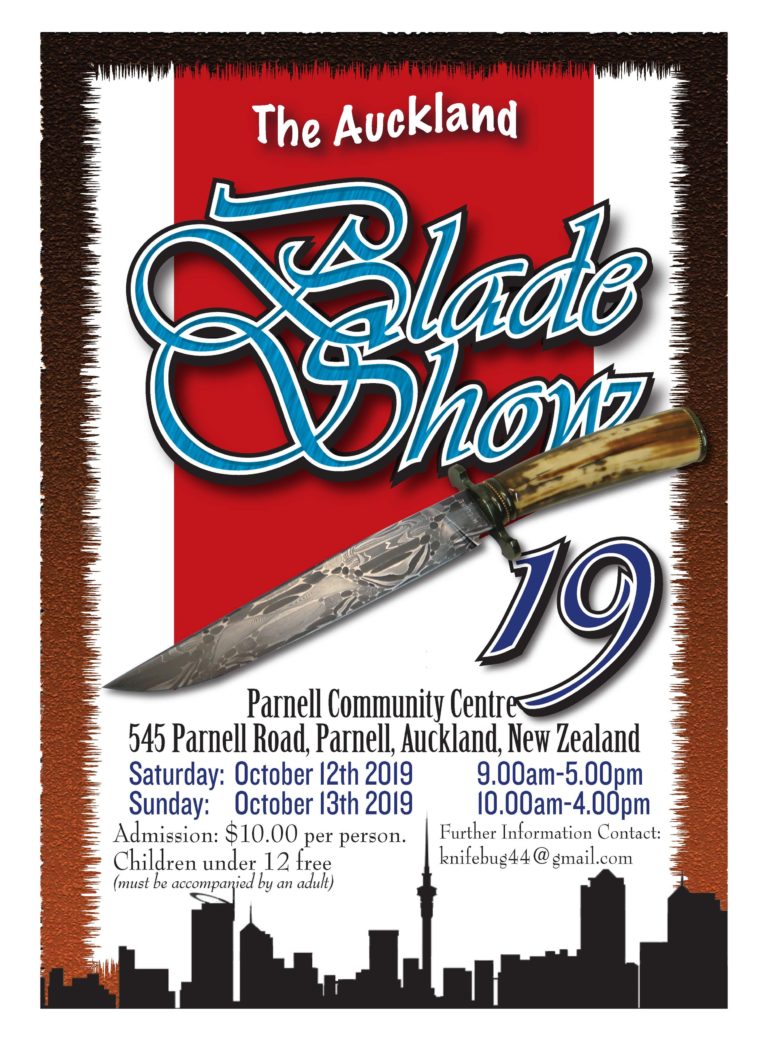

The Auckland Blade Show is back for 2019!

Good news, the Auckland Blade show is back on again this spring. Same location, 545 Parnell Road, Parnell, Auckland and this year it’s on the weekend on 12 & 13 October. See their poster for more info.

The Shed will see you there.

How to fix that wavering drill

First we checked to make sure that the there was in fact some play in the quill and indeed the dial gauge showed run-out of over 0.5 mm, quite a significant amount of wobble. I felt vindicated and quietly pleased that I hadn’t dragged Russell away from oiling and balancing the wheels of industry on false pretences.

Sharpen up your drills

Back when I was sharpening drills as part of my punishment, I discovered there were slow spiral and straight-fluted drills for brass and plastic. You may need a straight-fluted drill. You can create this by “backing off” the first 3 or 4 mm of a spiral-fluted drill.

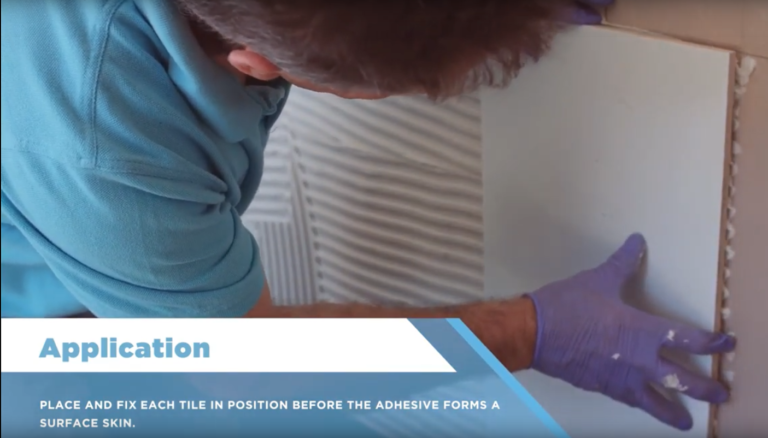

Tiling tips and advice thanks to Selleys

Got some tiling to do? Need some best practice tips?

Well here are three videos from Selleys with advice on fixing tiles to a surface, grouting and finally sealing the tiles.

Its all done using Selleys products so you can be sure of a great result.

Enjoy.

Industrial style at home

For the centre, I had intended to use one-inch (25.4 mm) diameter stainless steel that I had left over from a previous job but the lamp we purchased came with a one-inch chrome-plated tube which I decided to use. It also came with a screwed insert in the top for attaching the lamp and this saved me from needing to make an insert.

If you use stock tube, you will need to make an insert to fit in the top of the tube to take the lamp you purchase. This could be a nut you can find with the same thread as the lamp and where you just need to have the outside diameter reduced or you can make an insert and thread it accordingly.

Double the good news for our Australian readers

The latest issue of The Shed, Issue 84, is on-sale all around Australia this week. Click on this link for the latest retail outlets near you to pick up a copy

https://www.theshedmag.co.nz/home/2018/9/5/find-your-local-australian-the-shed-retailer

But wait, there’s more. For the final time, we also have a limited number of copies of our special edition publication Best of The Shed also on-sale in all Australian states. This is the last of our stock of our Best-of 10 years of The Shed.

Find your local Australian retailer for Best of The Shed magazine

Our great anthology of the best projects from the first 10 years of The Shed is now available in Australia at all good newsagents. Use

Have you got that in nylon?

Need nylon fasteners or washers? Hi-Q Components is the go-to solution for the widest range of nylon screws, nuts, bolts and washers in both metric and imperial sizes for all engineering or assembly needs. Threaded rod in 1-metre lengths is also available in M3–M20 sizes. Hi-Q Components also stocks flat, self-retaining, and insulating washers in many sizes. To buy online or for further information, contact Hi-Q Components on 0800 800 293, email [email protected] or see.hiq.co.nz.

Calling all skilled model makers and miniaturists

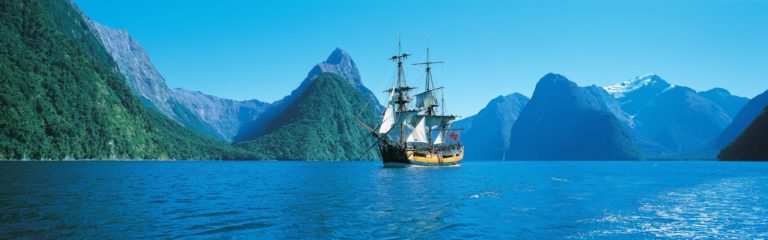

The New Zealand Maritime Museum in Auckland is currently seeking skilled model makers and miniaturists to volunteer in their fully equipped Model Maker’s Workshop.

The museum has embarked on an ambitious project to build a replica model of Captain Cook’s HMS ENDEAVOUR, to commemorate the 250th anniversary since the first onshore meetings between Māori and Europeans.

The museum estimates it will take a team at least 2000 hours to complete the build of the model.

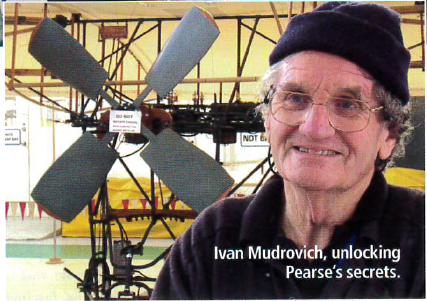

An engine imagined

“The sound of that Pearse wing destroying itself in a matter of seconds as it tore itself apart in a chain reaction fashion on the 14th September in 2012 at Whenuapai Air Base is a sound that I don’t think any of us will forget for a long while.” Retired Air New Zealand captain, Neville Hay as test pilot was not apprehensive but noted, “You have to think about everything you do. You can’t rely on memory of flying the plane.”

Black oxide finish

The particular process we are looking at in this article does not effectively alter the dimensions of the part as it etches into the surface rather than deposits on top. Black oxide finish is sometimes called parkerizing and it is common on components such as gun barrels because it does not involve high enough temperatures to cause distortion and there is no dimensional change.

The Shed, May/June 2019 issue no 84, in shops now

In the May/June 2019 Issue 84 of The Shed we share the amazing skills on one Daniel Strekier who built himself his own extraordinary bicycle… almost entirely out of wood!

It really is something to behold and you just have to sit back and admire the skills that went into making this incredible piece of usable art.

Jude Woodside sits down with Brent Sandow and gets all the background on this, NZ’s most accomplished knifemaker, who shares his inspirations and skills with us.

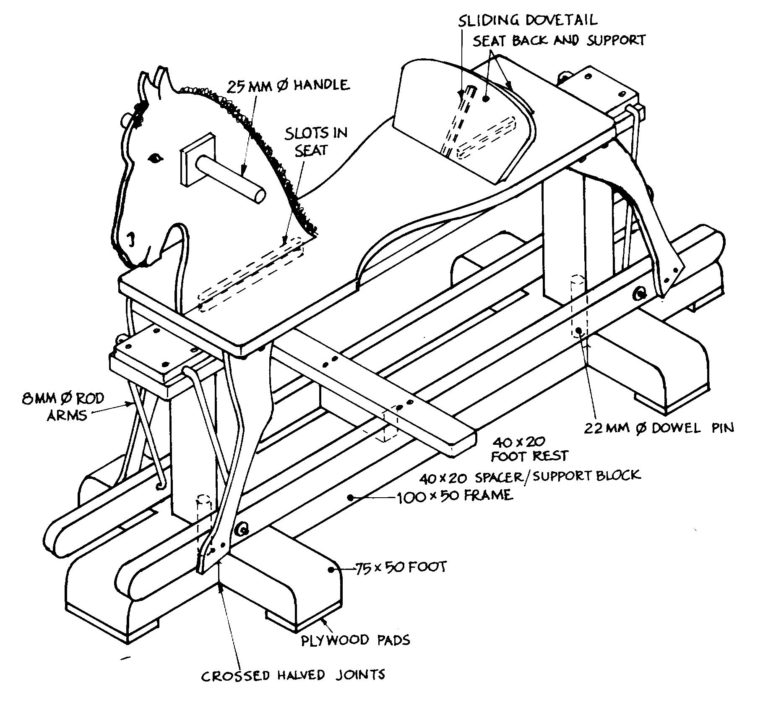

Build a rocking horse

I made the prototype of this rocking horse more than 15 years ago not having the recipient present to measure against I approximated the sizes. It was a good fit…for me, but sadly not for a potential junior jockey. The next model I attempted was suitably scaled to a more appropriate size and with a few refinements is presented here

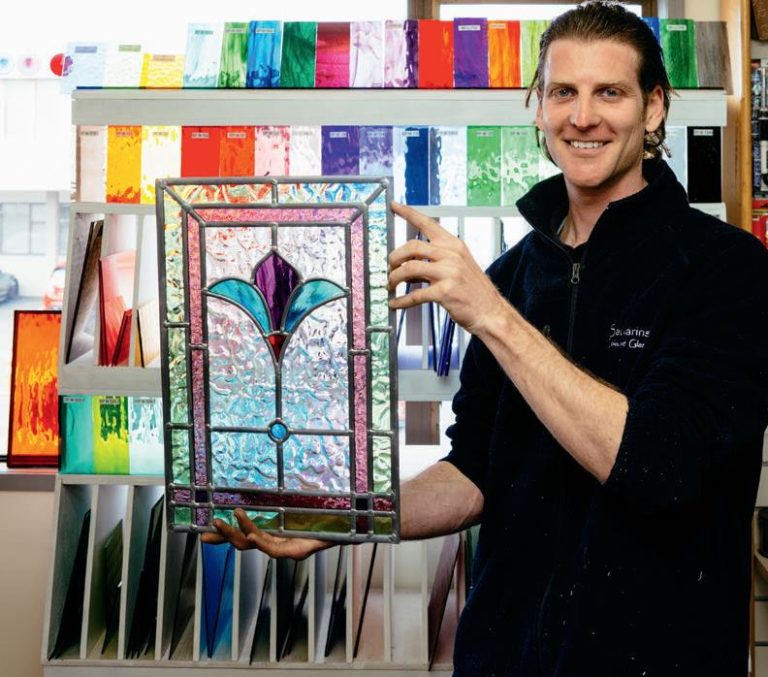

Totally transparent

Chance is a fine thing. When Myke Bakker’s mother decided to do a leadlight course when he was a high school student and brought the tools home, she unwittingly set on course a chain of events that would influence the direction of her son’s life.

“I was fascinated by the whole process and started mucking around,” says Myke. “I made my first leadlight when I was 17.”

Fourteen years later, Myke is still intrigued by the many possibilities of working with glass and he’s made a career out of it in the process. He is one of a small team who work at Sauvarins Coloured Glass Studio in Auckland’s Penrose specialising in all things glass.

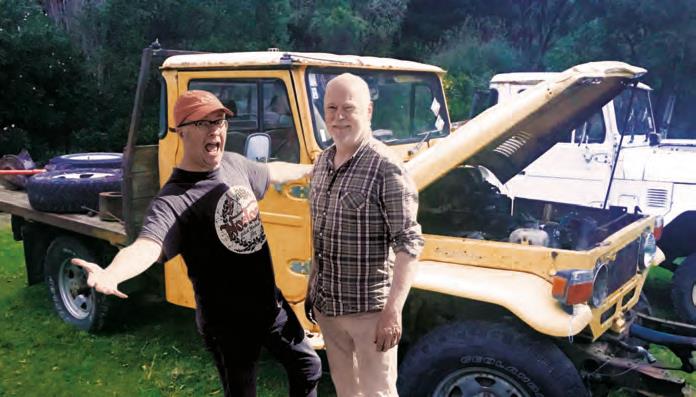

New Kiwi TV show – Start me up

Start me up is the world’s first car show based on the phenomenon of “cold starting” – an online craze where cars that haven’t run for years or more – typically decades have their engines fired up or “cold stated”.

Screening now on TVNZ On Demand and soon on the Duke channel. Click ‘Read more” to get the full rundown on the show.

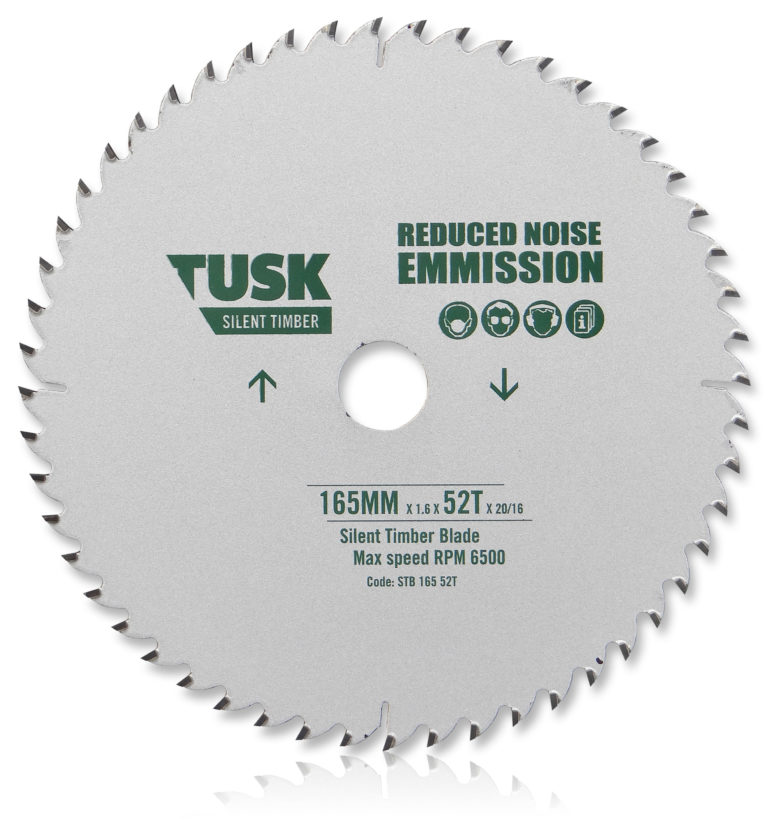

The sound of silence

Tusk, a brand offering a range of ‘cutting solutions’ — including demolition-grade blades which go through nails and even stainless bolts — also markets a 185 mm ‘reduced noise emission’ circular saw blade they are calling the Tusk Silent Timber Blade. Reduced noise emission, yeah, but silent?

A summer 2019, sheddie’s tale

Back in the early ‘70s, an Auckland bloke gets hold of a 25 hp Sea Horse Johnson outboard motor – it’s knackered but it has potential.

He takes it all to pieces, orders all the bits to get it up and running again then wraps it up, bits and all, in a New Zealand Herald newspaper and packs it in a box, presumably as a rainy day project. For reference, the outboard is from 1970 and the Herald is from December 1975.

A racy go kart

First off, we had to come up with a basic design under the KISS (Keep It Simple, Stupid) rule, keeping in mind the fact that the kids are getting older and harder on the gear. So I decided that easily replaced components were a key at this stage. Number One son is only going to get taller and no doubt half the neighbourhood would want to have a crack at setting the fastest lap around the street, so we had to include an adjustable one-size-fits-all seat in the design.

Fire in the beer can

The cans energy drinks come in are a tad on the small side for this project. Scribe a line completely around each can 30 mm up from the base. Cut along this line with an ordinary pair of scissors. The idea is that the bottom section of one can forms the base of your stove.

Shed 83 on sale throughout Australia today

The Shed Issue 83 on sale today throughout Australia. Find your nearest stockist here.

https://www.theshedmag.co.nz/home/2018/9/5/find-your-local-australian-the-shed-retailer

The art of coachbuilding

Many of the old crafts that had been around for centuries have been almost lost in our modern age. Among them are the crafts of those who used hand tools and tapped into centuries of passed-down knowledge, the blacksmith, the wheelwright and the coachbuilder.

Coachbuilding with wood has been around for more than 500 years. The restoration of vintage cars is helping keep this craft alive in New Zealand—just—and there are only a few people here who still have these skills. One is Neil Carter of Normanby in South Taranaki. He specialises in restoring veteran cars (made before the end of 1918). These vehicles had wooden frames and bodies made by coachbuilders in the days when the horse and carriage ruled the highways.

Wooden toys – make a Flintstones’ Car

The toys are made from kiln dried, pine, kindly donated. PVA glue holds everything together. I avoid metal hooks or eyes, which may be unscrewed or cause injury. The toys are undercoated, painted with acrylic paint and finished with a coat of Polycrylic ™which gives a gloss finish for cleaning. I find the Resene™ test pots a worthwhile ‘investment’.

A home-made Kontiki built from scratch

Over the years I’ve tried sails, kites, giant bags, kayaks and surfboards to get hooks out where the fish are. After watching torpedos on the beach, I find it is now obvious that there really is only one way and it requires 12 volts and a motor.

Of course every challenge is only really about what you can learn in the process, so I set about building a kontiki torpedo and winch from scratch for as little as I could. I had to enlarge my capabilities especially in aluminium casting, plastics forming and in electronics.

Calling all agricultural innovations

Entries are open for the Fieldays Innovations Awards, a unique chance for agricultural innovators to test their ideas, gather information, launch products, and make connections.

Award categories include the Prototype Grassroots, for new innovations, the Prototype Established, which recognises product development, Launch NZ, which is for innovations ready to go to market, and International for launching innovations globally

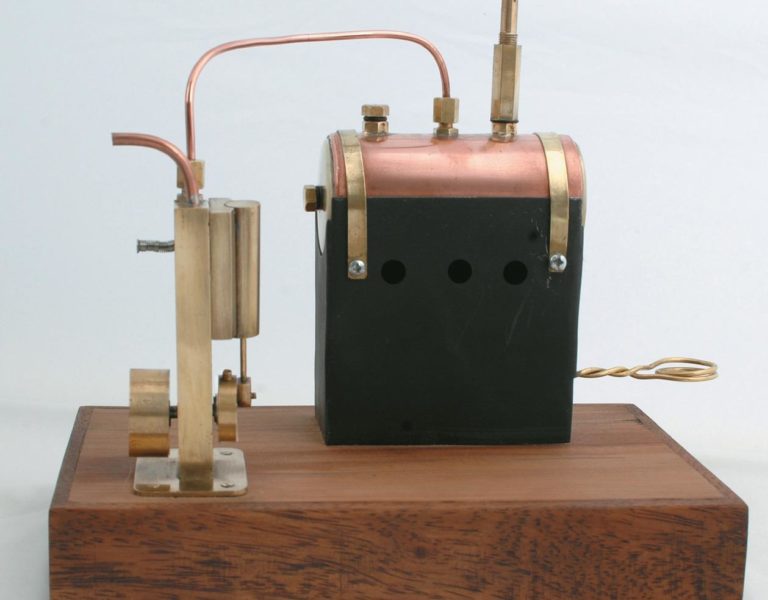

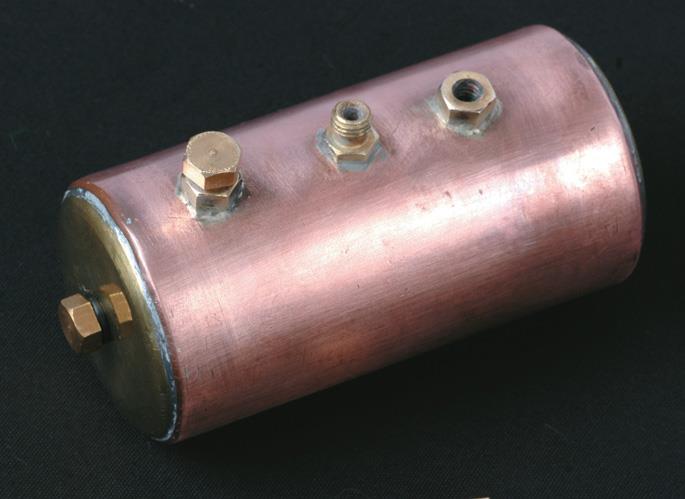

Build a small steam engine – part two

Although daunting at first, it is fairly logical if tackled a small step at a time. The use of a lathe is desirable but with a little lateral thinking it would be possible to make it without one.

First the cylinder is made from a short length of 12 mm round brass rod. Mount this in the three-jaw chuck of your lathe and face off one end. When turning brass it is necessary to grind the tool with a negative rake (see diagram). Brass is extremely brittle and the point of a tool bit with a positive rake would bite and snap off, being thinner and weaker.

The Shed, March/April issue no 83 on sale now

In the March/April 2019 Issue 83 of The Shed we get stuck into that huge home job that, when you do yourself, can save you thousands of dollars – house painting.

We talk to to the paint and filling product manufacturers to get all the latest technical info and arm you with advice on how best to undertake this very important part of home maintenance. With the current paints, technology and fillers you will learn techniques and methods that may amaze you.

Building a small steam engine – part one

Originally devised as a plaything for young boys, they quickly became the sort of toy that a lad was only allowed to play with on special occasions. They returned for a brief period of popularity during the 1960s and 1970s but even then were more adornments for a bookcase rather than well-used toys. This was probably due to the exorbitant cost of the product rather than any regard for safety.

Shed 81 subscriber prize winner

One of our favourite jobs here at The Shed magazine is giving stuff away to our loyal subscribers. So here is the lucky winner of our subscription prize in Issue 81, a stunning Charmate Offset Smoker Pack worth $1300, is Dennis Hastie of Taranaki. Congratulations Dennis, time for you to go low & slow cooking.

If you want to get in on our subscriber prize draws head to https://magstore.nz/…/the-shed-magazine-subscription-options to sign up.