This decorative water wheel will add interest to your garden

By Stuart Lees

While we are rather spoilt these days for ready sources of energy, it was once a matter of harvesting what was available in the local environment. More often than not, what was available was a stream or river, and so the workshop was built on the riverbank and the harvesting was achieved by a water wheel.

I’ve always been rather taken by the concept of water wheels (and other mechanical devices that harvest energy from nature), and have been intending to make a small one of my own, even if it was just to be a garden ornamental feature.

You may well ask, just how many ways can you actually make a water wheel, and the more I thought about it and the more research I did, the more surprised I become about the breadth of the topic. I found a particularly interesting reference, quite the authority on water wheels. It is “The Engineer’s and Mechanic’s Encyclopædia: Comprehending Practical Illustrations of the Machinery and Processes Employed in Every Description of Manufacturer of the British Empire”![]() by Luke Herbert, and the title is quite the mouthful. Interesting to find a book that has such a strong understanding of the science of water wheels. Of course, that it was written in 1836 might have something to do with it!

by Luke Herbert, and the title is quite the mouthful. Interesting to find a book that has such a strong understanding of the science of water wheels. Of course, that it was written in 1836 might have something to do with it!

When planning on a water wheel, the type is heavily dependent on where the energy is coming from. Where water is available at a height, then it has potential energy that can be harvested as the water drops. The theoretical maximum available is mass x gravity x height. (Theoretical, because there are always losses in the real world).

Where water is flowing/moving (such as a stream), then there is kinetic energy available, from the force of the water hitting each blade of the water wheel. In this case, the energy is equal to ½ the mass x the velocity2.

Overshot wheel

The first scenario uses an overshot wheel, where water enters at the top, collects in each bucket and the weight moves the wheel. For an overshot wheel, the water acts over approximately 180o of the wheel rotation. In some situations, it is not possible to get the water entering the wheel at the top and instead can only come it around the midpoint. This is called a breastshot wheel, or a breast wheel. The water acts over 90o, which is a lot less efficient overall than the overshot, but is still a good option if a full overshot situation is not available.

The second scenario uses an undershot wheel, where the wheel sits partially submerged in the current and is turned as the water flows past.

In some situations, the water is not only available at a height, but is also flowing with sufficient force to be able to drive a wheel around. My intention was to design a wheel that could be used for this final scenario – turning with the weight of water when it is slow-moving, and additionally being able to benefit from the turning force when flowing with sufficient velocity (even if the quantity of water is low).

The build commences with the fins. They are the key to all the other dimensions of the water wheel. In other water wheel designs I have seen, two, even three boards have been used to create each bucket that captures the water. While I am sure it is not a unique concept, I played around until I had a design that only needed a single board for each bucket.

This has a number of advantages. Firstly, the simplicity of the build, and although there is a bit more fiddling about to get the wheel together, overall the concept is straightforward.

The second advantage is the number of joints is minimised, and with it the chances of leaks. The more the wheel leaks, the overall decrease in efficiency.

Wheel efficiency

The third advantage also deals with wheel efficiency. This design provides pockets with significant capacity, and yet keeps the centre of balance of each bucket payload as close to the outer rim as possible, maximising the turning moment it exerts on the wheel. It also allows the fins to be orientated in such a way that a jet of water could push on them directly, and still maintain a storage area that was as far from the centre of rotation as possible.

The boards for the fins are planed flat and square and taken down to the required thickness using the planer and thicknesser. I decided to make them 15mm thick – this gave them sufficient strength (especially as this design also uses the fins as a structural member, holding the two outer rings of the wheel together) while keeping weight as low as possible. It is normally a good idea to take these initial steps. Boards that have been stored, even in ideal conditions will often get twists or cupping, particularly if it wasn’t perfectly dry and stable when it was obtained. The more straight and true (and flat) the boards are before you start cutting out the individual components, the better the resulting job will be.

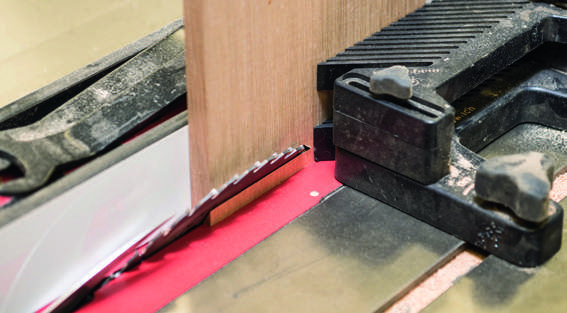

Next, the boards are taken to the Sliding Compound Mitre Saw (SCMS) to be docked to length. Each board is set to rest against the next, to create the pocket that will hold the water. To increase the surface area of that contact, the board is cut at an angle of 300. While not strictly necessary for a working wheel, I also relieved the outside edge of each fin to the same angle. This will minimise the amount of water that will bounce off the edge of the fin, and instead allow a small amount more to be collected instead. I wasn’t able to cut this angle easily on the SCMS, so instead, it was done by angling the blade on the table saw.

A feather board was used to help support the board against the fence. In this case, it was a MagSwitch feather board with a riser extension to get the extra height. If you don’t have a commercial feather board, one can be made quite easily by cutting parallel slots in the end of a board using a bandsaw. You can see quite clearly here the benefit of a left-tilting table saw. The waste offcut falls away, down onto the table rather than being left sitting on top of the blade, asking to be thrown.

Rudimentary wheel

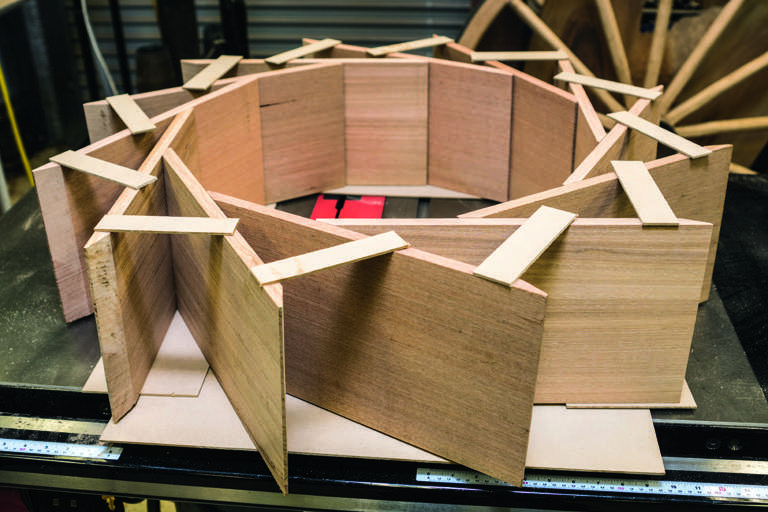

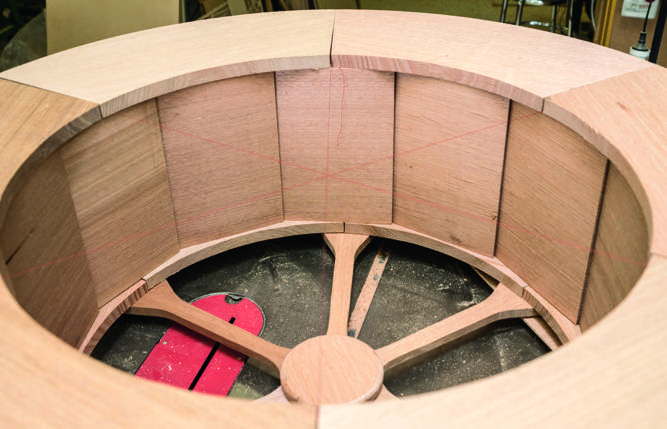

Each of the boards is bought together to form a rudimentary water wheel, allowing angles to be checked, inner and outer diameters, and to secure each in position with scrap pieces of wood or MDF, making the job of attaching the outer discs easier.

With one side of the fins temporarily joined, the entire unit was carefully flipped over, and more scrap boards were attached from the other side. I found a 23G headless pinner exceptionally useful for this step. This is like a really small pneumatic nail gun, firing a very small gauge (23G) headless pin that can barely be seen, even in let in place for the resulting project.

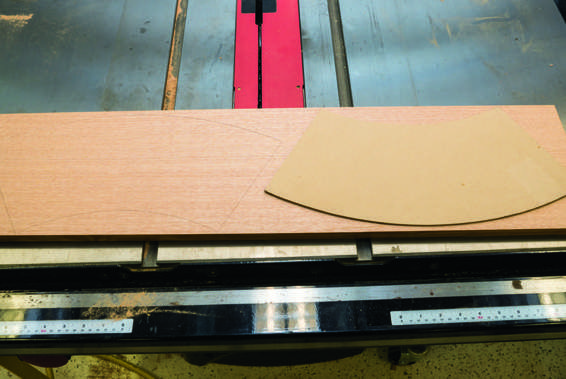

With the inner and outer diameters measured, this data was transferred lifesized to a 3mm MDF board. That was a particularly large circle – bigger than any compass I have. So another scrap piece of 3mm MDF was used as a rudimentary compass, with a nail at one end as a pivot point, and a small hole for the pencil to protrude through at the required radii.

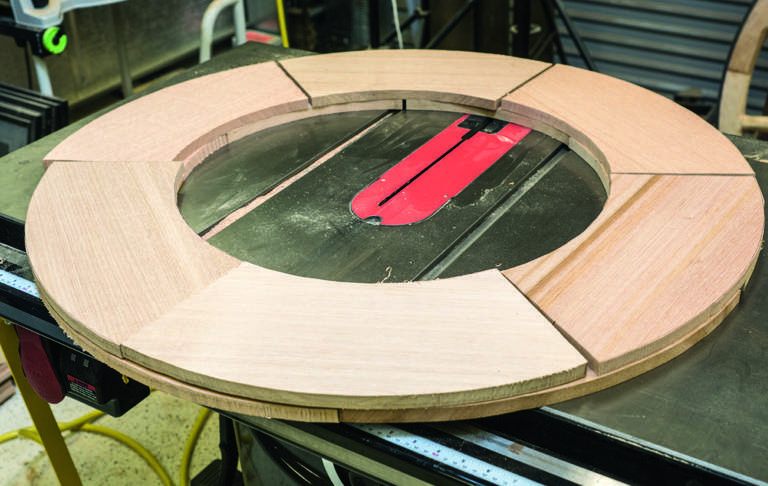

Having the life-sized circle allowed me to determine how many segments it would take, given the width of boards I had available. This was a very convenient six, particularly given the total number of fins was twelve.

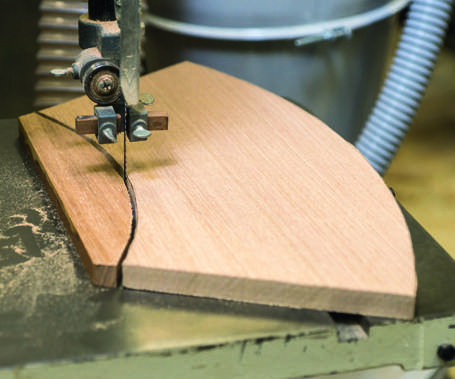

One segment was cut out roughly on the bandsaw, then sanded to the line, neat and smooth with a disc sander. Next, this template was used to transfer the pattern onto the dressed boards, ready to be cut out on the bandsaw. Twelve segments were needed in total – six on either side.

The bandsaw, with a ¼” blade was used to cut down close to the line. At this stage, it was not important for the cut to be exact, so long as the cut didn’t stray to the wrong side of the line.

Template bit

As I already had a template of the required shape, this was easily secured to the roughly cut segment (again using the micro pinner, although double-sided carpet tape is also very common). A router table with a template copying bit was all that was needed to finish the segment. Firstly, I cut a 6mm template from the 3mm one. I have found this is necessary, as a 3mm board is very susceptible to any forces exerted on it, which slightly crushes the edge, making the template unusable. A 6mm thick template provides more surface area for the guide bearing to ride against. Using a pattern copying (template) bit, duplicating the template exactly, whether this is into another piece of MDF, or the timber for the actual project is easy. A template bit is a straight cutter (often ½” / 12.8mm diameter) with a bearing on top which is exactly the same diameter. As the bearing runs against the template, the work is routed so it is flush with the template’s edge.

This can be repeated time and again. An MDF template is cheap to make, is easily shaped and sanded to the required dimensions and shape, and at the end of the project can be stored in your ever-increasing template library for future projects.

When making this template, I deliberately made the curved length a little longer than necessary. While it could be made exact, to ensure that the final disc accurately fits the circle of fins from earlier, I trimmed the ends of each segment as I went to ensure the best fit.

Accurate results

With both sides laid out on the table saw, I could get an accurate idea of size and fit, ready for the segments to be joined to the fins. Again, these were initially pinned in position with the 23G headless pinner so I could refine the fit before bolting it all together.

With the size confirmed, it was back to the bandsaw to create another MDF jig, this time for the spokes. Using 3mm MDF to start with, I created one half only, as I would then be able to use that to mirror it onto a piece of 6mm MDF and get a more accurate result.

The resulting spoke looks a bit strange and arrow-like initially, but this all makes a lot more sense when seen in situ. At the arrowhead end, again these were left wider than needed so they could be trimmed to form a tighter joint when all bought together.

The template was fitted to a piece of timber, ensuring the grain direction ran down the length of the spoke for strength, using either some 23G pins or double-sided carpet tape. The final shape was again produced with a template bit. One side of the spoke then had the edge relieved with a ¼” round-over bit (with bearing) to create a more refined finish.

You will also notice in the photos of the router table, the dust pickup. This unit not only allows dust to be collected right where it is being produced but also provides a starting pin to lean the workpiece against before engaging with the router bit, providing the operator a lot more control over the process.

Holes for the coach bolts are pre-drilled, again using a template to ensure consistent placement. Without the holes, getting the coach bolts in would be quite an exercise in futility. Even if you could get the coach bolt started, you’d pretty much be assured of splitting the work completely, which is still a problem if you use too small a diameter drill bit. Ideally, the drill bit is the size of the minor diameter of the screw, particularly in hardwood.

Lining up spokes

Lining each spoke up with the wheel takes a little bit of fiddling around. To make it easier, I used some cotton tied across the wheel, running through each of the gaps between the wheel segment. This showed me exactly where the whee centre was, but also helped support the spoke before I secured it in position. Once the spokes were all fixed in position, the thread was still easily pulled free.

Having the spokes come together at a point without being joined and supported would make for a very weak arrangement, so a disc was cut for each side of the spokes. This was done using a homemade circle-cutting jig on the bandsaw.

In basic terms, the jig consists of the pivot point that the workpiece revolves around, that is fixed at the required radius from the blade. The whole table of the jig slides into the blade until it hits a stop where the blade and pivot point are adjacent, and then the workpiece is rotated into the blade, cutting the circle.

Each disc was then taken to the router table and had one edge rounded over with the ¼” round-over bit.

Again, holes for the coach bolts were drilled through, firstly through one disc, through each spoke, then most of the way into the backing disc. A long coach bolt was then used to tie the three together. This was repeated for each spoke, on each side creating a strong unit of spokes.

At this point, all the other coach bolts were also secured in position. All up, each spoke had seven coach bolts – 6 for the head (which also held each segment of the wheel ring together), and one at the centre (at the arrowhead end).

Additionally, each fin of the wheel had two coach bolts from either side, firmly securing the two outer rings of the wheel together. Some water wheels use metal rods to hold the outer rings together, but that is not needed with this arrangement.

Making the axle

The next job was to create an axle. I did have a quick look at how much a piece of hardwood dowel would cost off the shelf, but it was both unreasonably expensive, and too thin. Fortunately, if you have a lathe, this is not a restriction. I was able to quickly turn a 38mm diameter shaft and was able to leave one end square.

The square end will prove exceptionally useful down track if I ever decide to use the water wheel to power anything, as it will provide a coupling that is not prone to slippage. A Forstner bit was used to drill holes through the centre of the spokes, and the axle tapped home.

The frame for the water wheel is a very simple affair. It consists of an A-frame, with three support members on each side. The middle support member will also hold up the wheel. Rather than adding any additional structures to support the wheel, a half-round cavity is drilled that keeps the water wheel axle captive.

To drill this with a Forstner bit, a scrap piece of timber is clamped against the cross beam. Definitely do not try to use a Forstner bit without it cutting around its full circumference – it will kick sideways otherwise.

The two sides of the A-frame are tied together with cross members – at the bottom of each leg of the A-frame, and one at the top. Depending on what solution you choose for supplying water to the wheel, this top member can be replaced with a full tray or left as a simple cross-piece.

The lower section of the A-frame can also be left as is or can have a catchment tray added, particularly if you intend to recirculate the water with a pump.

With the water wheel in place, a couple of wooden washers are attached to the axle (on one side only), preventing the wheel from being able to move sideways.

I added some wax to the contact surfaces which allowed the wheel to spin a little easier, but it seemed to operate quite smoothly without it. Perhaps the bit of scorching caused by the Forstner bit added some natural graphite lubrication!

As mentioned earlier, the other end of the axle was left with a square end, so future couplings can be easily attached.

Initial testing

Initial tests of the water wheel proved very effective. Just with the water weight and force from a garden hose, it was able to achieve an impressive revolution rate. After a time, it got slower and slower which was a little puzzling for a second, until it occurred to me that I hadn’t sealed the timber yet, and it was getting heavier and heavier from absorbing water.

When it dries out, I’ll apply a timber sealer to it to stop this happening and to maximise the longevity of the wheel. What sealer you use absolutely depends on what finish you intend to use, as not all are compatible with each other. I haven’t decided what finish to use as yet – whether it will be a traditional oil (which I tend to prefer but needs recoating every year or so), or to go with something like a modern polyurethane.

I am a bit reluctant to go all modern on it, as I actually want the wheel to weather, and gain a patina of age, water damage, and neglect, so it really looks like a water wheel of old, and not something made quickly and cheaply that only vaguely looks the part without real character.

As you can see from some of the photos, I didn’t wait to apply a finish before trying it out!

Now all I need is a bit of a creak or stream (or a water pump), and the wheel will be off and running.

So that is my version of a traditional water wheel. Built strong and durable, and functional, and with the ability for any and all components to be replaced over time simply by unscrewing a few of the coach bolts holding it together. In saying that, if absolutely necessary, the entire unit could even be flat-packed (although I doubt you’ll see it in Ikea any time soon!)

A note about tools:

In my projects, I often refer to performing a step using one tool/machine or another. This is not to say there are not many other ways to skin a cat. For example, I use a jointer and thicknesser to true up boards, but if you are so inclined, a hand plane could have been used instead, or an overhead-mounted router as a couple of other options. An SCMS to cut boards to length could also have been performed (to varying degrees of success) using a handsaw, bandsaw, table saw, even a router, or a high-speed oscillating tool. It comes down to what tools you have, are familiar and comfortable with, and can use effectively and safely that will dictate what you choose.