Shed 83 on sale throughout Australia today

The Shed Issue 83 on sale today throughout Australia. Find your nearest stockist here.

https://www.theshedmag.co.nz/home/2018/9/5/find-your-local-australian-the-shed-retailer

The Shed Issue 83 on sale today throughout Australia. Find your nearest stockist here.

https://www.theshedmag.co.nz/home/2018/9/5/find-your-local-australian-the-shed-retailer

Many of the old crafts that had been around for centuries have been almost lost in our modern age. Among them are the crafts of those who used hand tools and tapped into centuries of passed-down knowledge, the blacksmith, the wheelwright and the coachbuilder.

Coachbuilding with wood has been around for more than 500 years. The restoration of vintage cars is helping keep this craft alive in New Zealand—just—and there are only a few people here who still have these skills. One is Neil Carter of Normanby in South Taranaki. He specialises in restoring veteran cars (made before the end of 1918). These vehicles had wooden frames and bodies made by coachbuilders in the days when the horse and carriage ruled the highways.

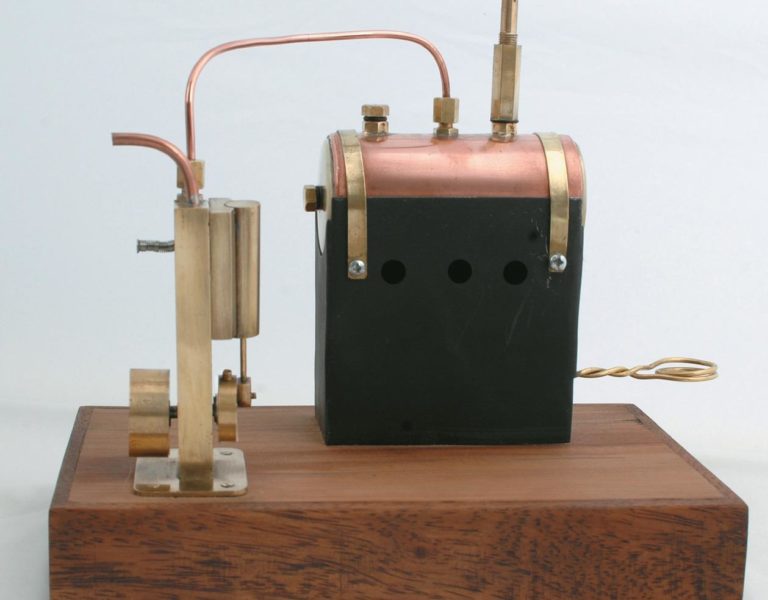

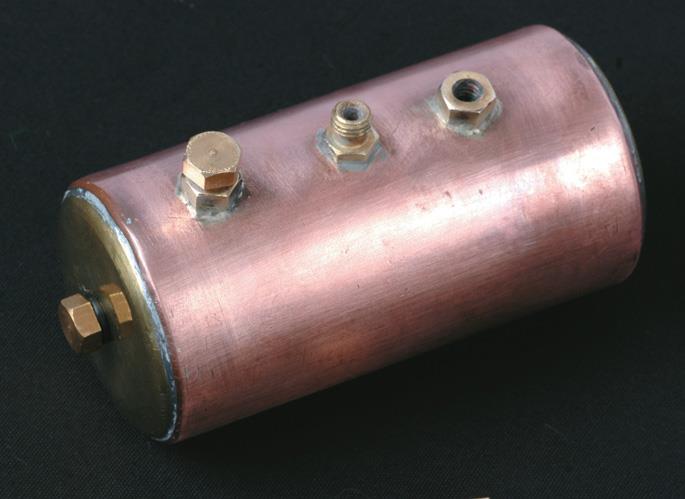

Although daunting at first, it is fairly logical if tackled a small step at a time. The use of a lathe is desirable but with a little lateral thinking it would be possible to make it without one.

First the cylinder is made from a short length of 12 mm round brass rod. Mount this in the three-jaw chuck of your lathe and face off one end. When turning brass it is necessary to grind the tool with a negative rake (see diagram). Brass is extremely brittle and the point of a tool bit with a positive rake would bite and snap off, being thinner and weaker.

In the March/April 2019 Issue 83 of The Shed we get stuck into that huge home job that, when you do yourself, can save you thousands of dollars – house painting.

We talk to to the paint and filling product manufacturers to get all the latest technical info and arm you with advice on how best to undertake this very important part of home maintenance. With the current paints, technology and fillers you will learn techniques and methods that may amaze you.

Originally devised as a plaything for young boys, they quickly became the sort of toy that a lad was only allowed to play with on special occasions. They returned for a brief period of popularity during the 1960s and 1970s but even then were more adornments for a bookcase rather than well-used toys. This was probably due to the exorbitant cost of the product rather than any regard for safety.

I regretted losing the Dyco as it was quite clear the newly acquired, imported machine I had purchased was nowhere near the quality. I bought the Tanner because I had an idea to build a small vertical slotting machine to cut small keyways and splines inside gears for my old motorcycles. I had made up a rather ugly prototype for a slotter as a proof-of-concept test which seemed to work OK.

But a very good friend of mine had recently built such a unit using an old unwanted drill press so this was the main motivation for this purchase.

This raises the possibility of casting wheels in aluminium. Casting aluminium is not as complicated as it may seem; common sense is the main ingredient. In the case of a tractor or traction engine which has two small and two much larger wheels, the contrast between the sizes is important. Further, the large wheels need to be wide but have thin tapered spokes.

In The Shed 82, the Jan/Feb 2019 issue, its time to join the low & slow cooking revolution – to do that we need to build our own offset smoker barbeque.

In our cover story this issue we showcase three sheddies from around the country as they have their own way of making a smoker just the way they like it. Two out of steel and one out of a wine barrel, yes, a wine barrel. We have all you need to know about low & slow cooking with rubs, woods, cuts – the lot. Get building, get smoking and get stuck in.

This design-and-make plan will enable you to make a small pan sheet metal folder that folds mild sheet metal from 18 to 26 gauge. With it, you’ll be able to fold “U” or “Z” sections or a lip on a sheet of metal. The way we’ve constructed the metal folder will also allow you to bend metal to more than 90 degrees—try that with two pieces of angle iron mounted in the vice.

In Issue 81 of The Shed, Des Thomson showed us how to solve the problem of sweeping up metal waste and nails from your workshop or shed. In this video, Des discusses the build, then displays the sweeper and its uses.

When I came to select an old gas bottle for this project, the most likely candidate proved to be full of gas. Far too much gas to vent so having committed to making the forge I opted for the second-best option and bought a new bottle. At only $45 it wasn’t a huge outlay although I know that many of you will be shaking your heads at my frivolous wastefulness.

Buying a new bottle has one very handy up side: there is no volatile gas in the bottle. If there was then certain precautions are absolutely essential.

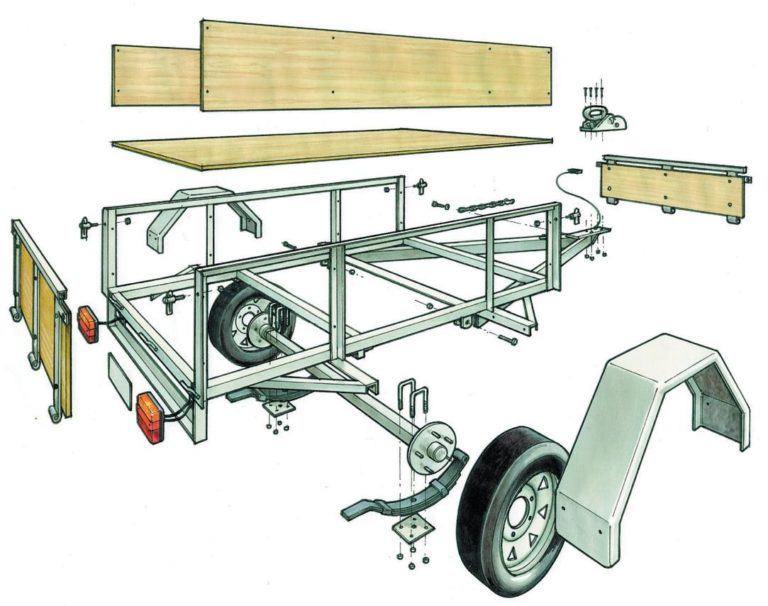

The frame is braced by angle-iron cross members and has a sturdy, ply wooden deck. It’s best to use not less than 5-ply 12 mm minimum — in this case we have used 7-ply 17 mm. With minor variations, I have built a standard 1200 mm x 1800 mm (6ft by 4ft ) domestic trailer with a solid frame of rectangular hollow section (RHS) mild steel.

Cambridge sheddie Kim Dawick decided to build a drift trike for a mate’s birthday. It was relatively simple and so much fun to ride he decided to build eight more to bring the old gang from school back together. Click through to see the Kim take Mike’s trike for a spin, and another one, and another one….

The 2018 Auckland Blade Show in Parnell this weekend was a huge success. Over 25 knife makers from all over NZ took stands as well as a shop from Gameco Artisan Supplies. A steady stream of visitors enjoyed an awesome display of great Kiwi knife making with no exhibitor quite like another. Organiser Brent Sandow promised us all we won’t have to wait as long for the next event which will require a larger venue to accomodate all the knife makers that couldn’t attend this 2018 Auckland show. If you are a fan of knives and knife making, do not miss the next show.

A crucial step in building this trailer is to get the axle stub straight, otherwise your tyres will chop up as they run. I use a jig of angle iron to get this straight. But I can show how to do it for home workshop, simply by holding the axle stub firmly against the bottom and one side of the box section axle to ensure it is square. There must be good welds on the axle stub.

The Shed magazine is eclectic, informed, and always fascinating. Aimed at those with a few tools and perhaps a few clues: this is the magazine for real sheddies.

Packed with ideas, projects, advice, and peeks into other people’s sheds providing inspiration, ideas, and techniques, or just for the sheer enjoyment of the sheddie’s endless inventiveness, The Shed is the project enthusiast’s bible.

Sign up here to The Shed monthly email newsletter for exclusive reader offers.

Sign up here to The Shed monthly email newsletter for exclusive reader offers. For signing up, we’ll send you a free copy of The Shed, just simply put your postal address in the form.