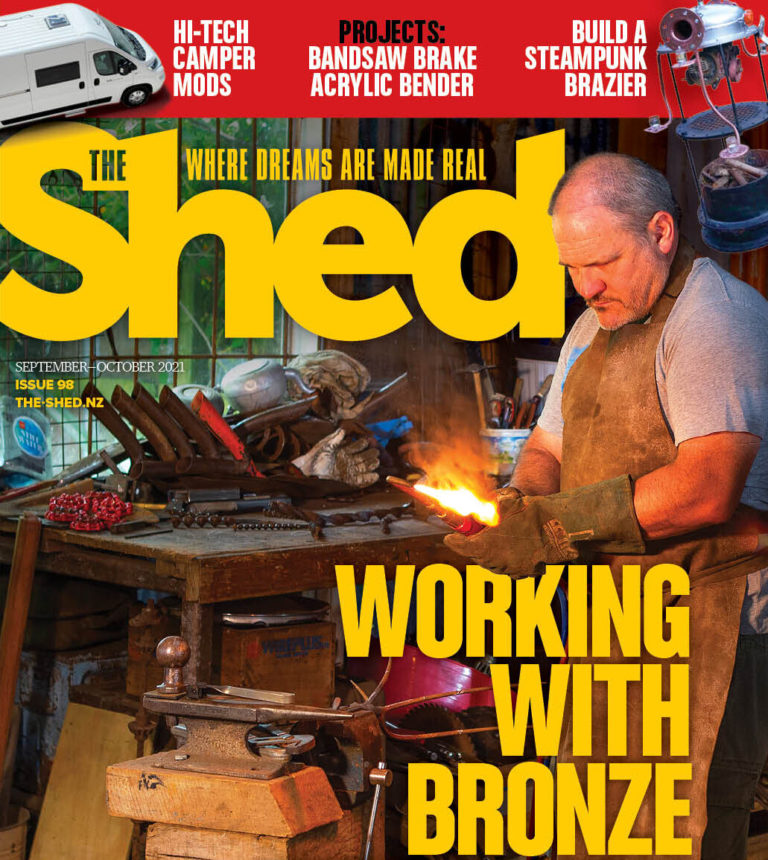

Video of bronze sculptor and junk artist Glen Macmillan from The Shed Issue 98

Glen Macmillan works between his two sheds creating sculptures from recycled waste. A large part of what Glen creates, though, is made from bronze, and he shares with us his method of casting bronze using the lost wax method. This is an ancient process that serves him well in the creation of sculptures large and small. In this short film, Glen shows us the steps to bronze casting and we watch him in his workshop while he creates a junk sculpture.