Retired tradies learn skills – and make friends – restoring railway carriages

By Nathalie Brown

Photographs: Derek Golding

Every Wednesday and Saturday morning about 20 retired tradesmen leave their lunch boxes in the Oamaru Steam and Rail smoko room, shrug themselves into their overalls, and head for the old railway workshop to get on with the day’s tasks.

They might be restoring turn-of-the-20th century railway carriages, stripping down a locomotive or installing wiring systems. Each man brings a lifetime’s worth of skills and the willingness to learn something new.

They work out of the old New Zealand Rail wagon workshop, or lifting shop as it was called, at the back of Oamaru’s historic precinct. The Oamaru Steam and Rail Society Inc took over the building in 1989. Most of the tools and equipment needed to complete the volunteers’ first major project were on hand so they rebuilt the 60mx12m workshop which had been partially demolished by NZ Rail when they decamped.

Several of the volunteer sheddies bring tools from their home workshops; these include magnetic drills, welders, lathes, drill presses, and all the woodworking gear needed to make the shapes and mouldings.

“You’ve got to really love the work to spend much time out here”

Puke, poo, and diesel

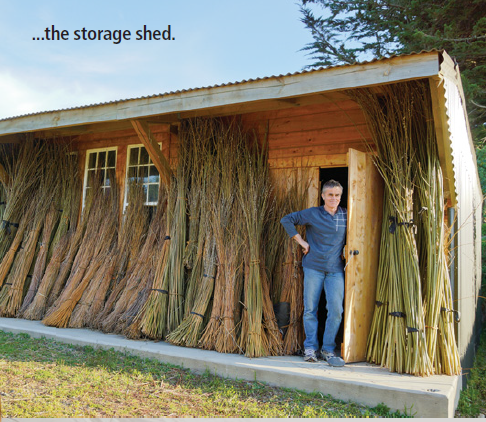

But the bulk of the equipment can be found at the back of the workshop in three old corrugated iron storage sheds. This is also where a few little Blue Penguins make their homes. The air is rich with the smell of engine grease and diesel fumes overlaid with penguin puke and poo. You’ve got to really love the work to spend much time out here.

But it’s where Harry Andrew, manager of the outfit, stores an impressively tidy collection of metal pipes and poles, gigantic metal structures, tools, and equipment once used by NZ Rail. And he knows pretty well what’s here, right down to the last bucket of bolts and sprockets. The sheds aren’t big enough to store everything, so more iron is stored in old carriages out the back, and down the sides of the workshop.

Harry sources anything else that might be needed. He writes the grant applications for items required for specific projects, and because everyone in town knows Harry and the impressive work he does, he is well received when he visits local engineering shops asking to borrow specialist equipment like a Rotabroach for drilling extra big holes, or thread cutters for bolts and pipes.

“We drink a lot of tea and coffee and spend ages talking about technical problems”

Community railway

In the late ’80s, through a fair bit of wheeling and dealing, the Oamaru Steam and Rail Society Inc secured about 2km of dedicated line from the little station on the edge of the historic precinct – called Harbourside – to the disused quarry at the far side of the harbour, very close to where the Oamaru Blue Penguin Colony now stands. They offer train rides for $20 family, $8 adult, $3 child every Sunday and, together with Dunedin Railways, do occasional excursions to Herbert, 22km south of Oamaru.

It’s a community railway. There are 110 members in the society and a good number are families who join for the discounted rides on offer. There are some 20 maintenance workers and about 15 Sunday workers, some of whom double up. A trained crew of five works on Sundays to operate the little railway: there’s a ticket seller, the station master, a guard and assistant guard, a driver – sometimes two drivers for diesel, and a fireman if it’s a steam train. They work under the Land Transport Authority rules and people have to be qualified to run the trains, even on a 2km track.

Harry Andrew, the manager of Oamaru Steam and Rail, can trace his involvement with the railway in Oamaru back to the centennial in 1962 when he rode on the trains as a 15-year-old passenger.

Highly skilled team

Most of the volunteers bring specific skills to each job and the workshop can call on a fitter and turner, an electrician, tinsmiths, plumbers, a car painter, a house painter, motor mechanics, and general engineering. There are also retired white-collar workers with impressive DIY skills.

Harry says, “Most of the men also come here to learn different things – things to do with compressed air, electrical things, mechanical things. A lot of people haven’t had those linked and they learn how to link them here.

“If we come up against any problems around repairs and maintenance, we discuss it in the smoko room. The ideas are sketched out on paper and if necessary we do a bit of internet research. We drink a lot of tea and coffee and spend ages talking about technical problems. From the smallest task to the big jobs – there’s no rushing in.”

“We decided that, with enough money to pay for the parts, we could do a better job ourselves”

Train WOFs and safety

Harry points out that in the past five or six years, the club has focussed on doing the work rather than just cleaning up and painting.

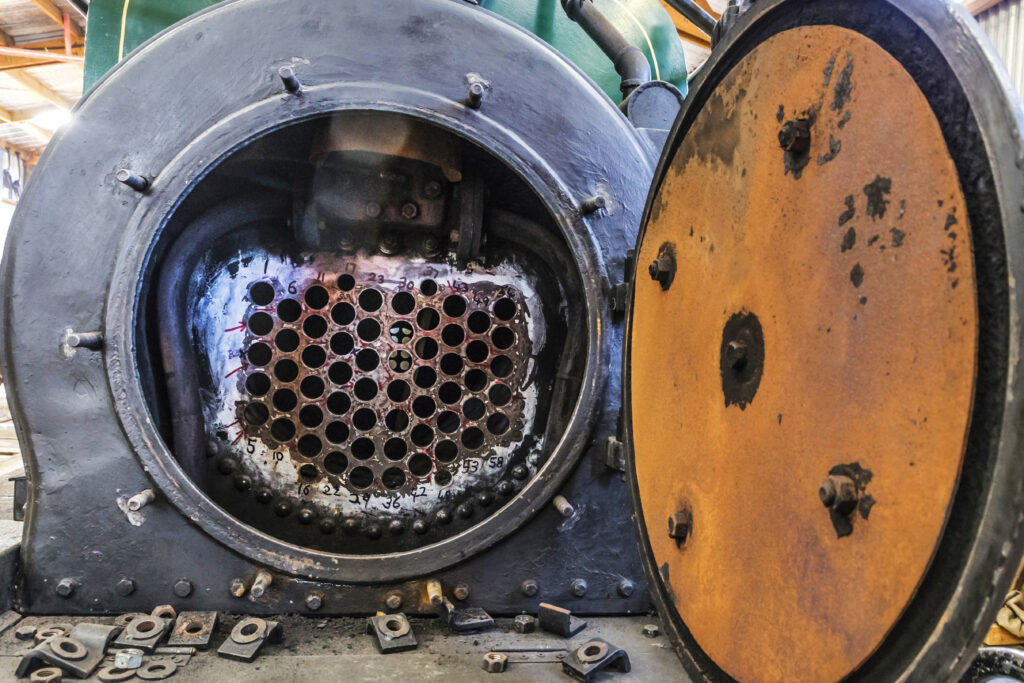

“We used to farm out the work but now we do as much as we can on our own. We farmed out the steam loco to be refurbished and decided that with enough money to pay for the parts we could do a better job ourselves. In fact, we save more money by doing it in-house and the men enjoy it more. Recently we were working on brakes. We’ve modernised one loco that didn’t have the proper brakes and couldn’t do the job Land Transport wanted it to do, so we’ve designed new brakes and put them in.

“Every year we’ve got to do a Warrant of Fitness for each loco, bringing them up to a safety standard that complies with NZTA specifications. Then all the time we have maintenance to do on the locos, because they’re old. They break down and you’ve got to make parts using a lathe, a drill press, all sorts of welders, and woodworking equipment.

“Our biggest concern is safety. No shortcuts are taken. We don’t expect anyone to take on big, heavy work alone. We share it out and work together on it. We have a few women involved in the station work, and one woman just loved to cleaning our locomotive B10 but here, by choice, the men do the heavy, dirty work.”

Good skills abound

Wally Smaill is a qualified plumber, drainlayer, and gas fitter who was the trades supervisor at the local freezing works for 32 years. He is building the new double seats for the open carriage, which require good metal and woodworking skills. He has completed the decorative wrought iron end of the seat and another one three metres further apart with wooden slats between. He uses a bandsaw to cut the ends and supports, belt sanders, and a handsaw for the rest of the woodwork. They use scrap metal to manufacture the bases that the bench supports stand on.

The sheddies have been successively laying concrete floor sections throughout the workshop, parts of which are still covered in the original orange Ngapara gravel flooring.

“They’re a great bunch of fellas and this really gives us something to keep us occupied two days a week”

Three-month project

Over the Spring of 2017 the volunteers spent much of their time building the Ways and Works wagon – a workshop on wheels. It will be used for track work, like replacing old wooden sleepers with modern concrete ones.

When The Shed visited, the Ingersoll-Rand compressor has already been bolted to the floor and John Paul (JP) is using a lathe to turn out a plug to go in the bottom of a gantry to take the weight when the men lift anything into the wagon. By way of conversation, JP says he served his apprenticeship as a fitter and turner and has his own machine shop at home.

Another two men are linking an air compressor to the reservoir tank underneath the wagon so they can use pneumatic gear.

Restoring the Ways and Works wagon is a three-month project, two days a week for about five men.

“There’s a lot of welding to be done,” says retired motor mechanic Kevin Conlan. “We’ve made new doors for it, put in a bench, a new metal-plate floor, a vise, and we are about to paint it. There are also the pipes to carry air the full 20m length of the wagon. We have yet to install a 12-tonne digger on the front end.

“Some of the other jobs we’ve done include replacing and painting the barge boards on the shed, reconditioning the red loco – the Husky – so we can take the old blue loco out of service and do repairs on that. And we’ve done quite a bit of track work, like replacing the wooden sleepers with concrete sleepers, which are a four-man lift. That’s why we want the digger on the front of the wagon.

They’re a great bunch of fellas and this really gives us something to keep us occupied two days a week.”

Plenty to do and learn

Some of the men are working on installing public address system wiring throughout the newly restored train carriages. The work is supervised by Phillip Screed, a volunteer and retired electrician.

The club members have restored two carriages: a 1904 and a 1924. The 1904 glories in 70 wooden slat seats, wrought-iron seat ends, wood-panelled walls, pressed-tin ceiling, and replica light fittings. The 1924 has also been rebuilt by the team of volunteers. When Harry found it, the carriage had been used as a welder’s workshop. Much of it has been restored but they have yet to bring in the grant money to restore the 40 leather seats. The guard’s van has also been rebuilt and to a certain extent reappointed. Volunteers built a heavy aluminium loading ramp to take the wheelchairs of disabled passengers, who ride in the restored 1947 guard’s van, which also houses the new PA system.

Ask any of the sheddies at the Steam and Rail workshop and they’ll tell you there’s always some new project to be worked on. There’s always something more to learn. And good friendships are being made and cemented among men who share a common interest.

Trading equipment

The railway equipment and spare parts stored in the three sheds and railway carriages behind the Oamaru Steam and Rail workshop are not always sufficient to do a particular job.

“We trade the equipment we’ve got in storage with different railway groups,” says Harry Andrew. “We belong to the Federation of Rail Organisations, New Zealand (FRONZ), which has about 90 railway groups and we can advertise in their magazine to buy, sell, or exchange most of the gear we need. The federation tries to keep all its costs down, so the magazine is only in an online format but as soon as they send it to me I forward it on to all the Oamaru Steam and Rail members.”

See the FRONZ website for the latest issue of their magazine