Basket weaver Mike Lilian follows an ancient craft

by Nathalie Brown

A tall man is standing in a plantation of willow rods. He bundles up an armload of pencil-thin rods, ties them together with a length of woven willow and carries them to the shed on the far side of the nearby house.

Of the scores of varieties of willow commonly used in basket weaving, six grow on a 1000-square metre plot at the back of Mike Lilian and Annemarie Liesbeth’s house in the coastal settlement of Kakanui, 15 minutes drive south of Oamaru.

Mike has been making and selling willow baskets in dozens of styles since 1985. Examples of his craft are on display in the work shed. There are picnic, laundry, log, bicycle, blanket, fruit and carry baskets of every kind. The Winchester is designed to carry six bottles of wine. Willow woven chairs, occasional tables, and cradles—even coffins—are stacked on shelves right up to the roof of the shed.

Self-taught

Mike, a self-taught basket weaver, established a reputation as a skilled artisan fir st in Oxford, North Canterbury, where he and his family lived for seven years before relocating to Christchurch in 1993. Then in 2005 he and Annemarie bought the 0.6ha block to establish the garden they had always wanted to allow for self-sufficiency with enough space for Mike to grow his own willow stock.

After a quarter of a century selling his wares at A&P and GardeNZ Shows, Mike was looking for a place where he could set up a display stand without having to break it down at the end of the event. The permanent exhibition he has created in Kakanui is his most ambitious display yet.

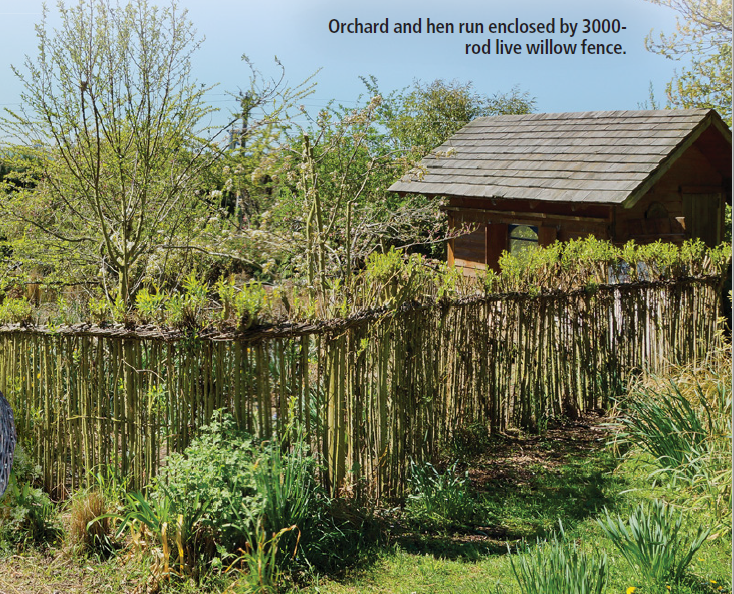

At the front gate, a wall of woven, live willow edges its way around Annemarie’s herb garden. The orchard, which serves as a spacious hen run, is enclosed in a giant willow basket. He planted and wove the 3000 live willow rods over two solid weeks one winter. He weaves the outdoor structures in the winter months when the plant is dormant.

Willow potager

At the top of a knoll just a stroll from the kitchen door stands an extraordinary potager: four knee-high baskets—each measuring three metres wide—are made of woven live willow. He makes the borders of the raised beds from basketry because they look beautiful and follow a tradition that goes back to medieval times.

In the middle of the potager beds stand elaborate wicker cones designed for growing climbers like tomatoes, sweet peas, and beans. A large willow cloche serves to blanche celery plants by protecting them from the sun.

In making the potagers and other live willow structures Mike harvests the willow stems, grades them for length and size, plants each wand and then uses traditional basketry techniques. “They are simply baskets on a massive scale,” he says. “Live willow needs contact with the soil in order to grow and the fact that they’re live means they won’t fall apart but there’s a lot of work in pruning them. I plant new structures and prune back the established ones every winter. It’s a lot of work but the results are worth it for me.”

A living willow wall, latticed around the outdoor dining area

Live willow

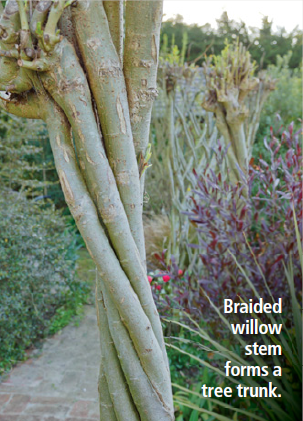

Throughout the garden, willow wands twisted into shape and then planted strategically make living sculptures. Braided willow stems form the trunks of the trees. Mike points out that the pencil-thin wands have grown to wrist-thick trunks in four years. Imagine what they’ll look like in 20 years time?

Latticed live willow acts as a windbreak for the outdoor dining area and forms arches framing the pathways to the lower reaches of the garden. Giant spheres made of willow cane are wedged between the branches of deciduous trees. These are often bought by Mike’s customers as focal points in formal settings.

His elaborate outdoor structures are featured in gardens throughout North Otago. He wove wind shelters and potager beds for the Waitaki Community Gardens and the gardens surrounding the multi-award-winning restaurant Riverstone Kitchen, 12 kms north of Oamaru on the Waitaki Plains.

But most of Mike’s work takes place in his shed. When he’s not in the garden he spends seven days a week there, although he says a few of those days are only four or five hours.

He gets deep satisfaction from what he does. “If I won a million dollars I’d make one basket a day instead of two.”

“Extraordinary potager” of three-metre wide raised gardens with basket-weave walls

A wicker cone for climbing vegetables

Rescue

Mike discovered traditional basket making as a career at the end of a long search for purpose and satisfaction. He had been working as a postman for 13 years, running to deliver the mail every morning and fi finishing his round in four hours. This gave him a full-time wage and his afternoons free to help raise his child, work in his garden and do up old houses. In 1977, he and Annemarie started a community in Christchurch where a group of friends bought up fi ve houses while three others rented. They shared meals, childcare, vehicles and offered one another company and support.

All the while, he was talking to people and searching for the work that would be both satisfying and meaningful. He wanted to find a craft that was dying out and dedicate his life to rescuing it.

He spoke to leatherworkers and woodturners who gave him the sense that he was getting close to where he wanted to go. On a visit to the Canterbury public library, he found an encyclopedia of traditional European artisan crafts and saw a photograph of a large circular basket full of hay on which cattle were feeding.

“I knew immediately that I wanted to make something like that—beautiful, useful and traditional,” he says.

He had heard of the Cooperite community in Canterbury who lived self sufficiently, grew their own willow and made baskets. He bought a bundle of willow from them, got a book from the library on willow weaving and started from there. Shortly afterward he and Annemarie and their daughter Lara moved to Oxford so that he could live in the country and teach himself to be a basket weaver.

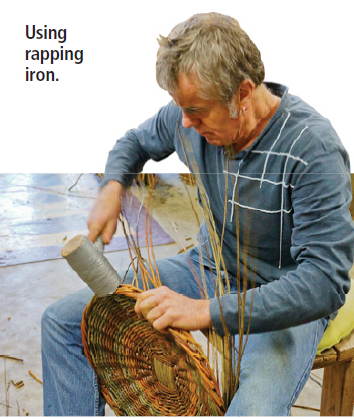

A basket weaver’s tools are relatively simple and inexpensive. In the early days, he made his own, grinding and polishing a large screwdriver to make a smooth pointed bodkin for creating spaces in the weaving. A rapping iron is a heavy iron implement shaped like a Maori mere and used for tapping down weaving to make it tight. He replaces his $140 Felco secateurs every three years and the blades more frequently. They are used for cutting pruning and trimming the willow. He also uses a rule, knives, and pliers of various types.

Skills

It took him a year of working virtually fulltime to learn to make a basket to his satisfaction. In 1994, after ten years of working alone and learning from books, he spent a month in the basket workshops of the Coopérative de Vannerie de Villaines-les-Rochers (Basket Weaving Cooperative of Villaines-les-Rochers) in France and returned for another month in 1996.

For the past 150 years, Villaines-les-Rochers has been the centre for wickerwork in France. More than 100 basket makers practice their art in workshops, some of which are located in cave houses. While he was there, Mike learned several signifi cant techniques but most importantly he benefi ted from expert feedback on his work.

“They knew scores of techniques while I knew less than half of what they took for granted. However, I was doing extremely well with the few techniques I was using, as good as anything I saw there, and I came back feeling confi dent in my skills.”

Mike makes about 300 items a year—he can make two hand baskets in a day—and goes through 1000 kg or one metric tonne of willow a year.

Record

He keeps track of every model he makes in a hard-bound notebook where he keeps prototype measurements. “Someone might want a basket for a 20 kg Labrador. I’ve got the specifi cations. I’ve got the instructions for different types of handles and plaits and measurements for wicker kitchen drawers.”

While he is working, Mike listens to classical music or to spoken-word tapes. His particular interest in the last few years has been the lectures of the late Joseph Campbell, the American mythologist and writer, best known for his work in comparative mythology and comparative religion. Campbell’s philosophy is often summarised by his phrase: “Follow your bliss.”

Mike’s own philosophy is best summed up as “hold fast to the treasures of our ancestors.” He regards the ancient tradition of willow basket making which pre-dates pottery as one such treasure. It must be preserved, he says. He has had an affinity with willow since childhood, having been introduced to the beauty of basketry by his maternal grandmother, whose name was Lilian. Born Mike Gillooly, he changed his surname to Lilian seven years ago to acknowledge his maternal ancestry.

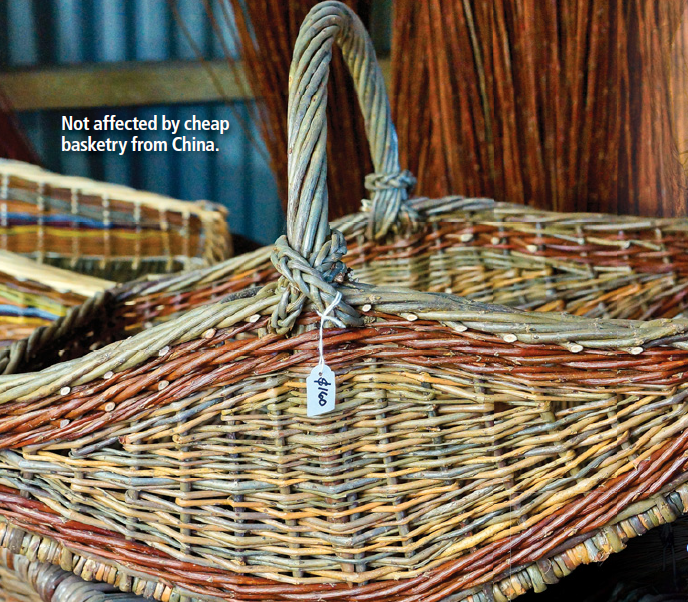

China cheap

Mike has created a niche market for his wares and says he is not in the least affected by cheap basketry from China. His fi first and most loyal clientele were rural women who discovered his range of baskets at A&P shows in the 1980s.

They appreciated traditional craft, accepted that a lot of time went into making each piece and were willing to pay a good price. His core clientele comes from repeat business and word-of-mouth. He doesn’t take out advertisements but has been the subject of a few newspaper and magazine features over the years. These brought in people from interest groups such as garden clubs. He doesn’t wholesale his works but kitchen joinery firms contract him for made-to-measure kitchen drawers.

Mike says he makes a comfortable income, similar to what a skilled tradesman would earn. Over the years a number of people have approached him to teach them the craft of basket weaving but most of them wanted to do weekend classes.

“When you’re looking at an artisan craft like this, you can’t learn anything of major significance in a weekend,” says Mike. He was looking for someone who was prepared to make it a life-time’s work, not a hobby.

Recently he has begun teaching someone who flies from the North Island every few weeks to spend several days learning specifi c techniques. He then goes home, where he has already established his own willow plantation, practices what Mike has taught him and brings the work back to Mike for comment and further instructions. It takes that kind of dedication, says Mike.

“You’ve got to be a fanatic to do it.”

Fruit basket

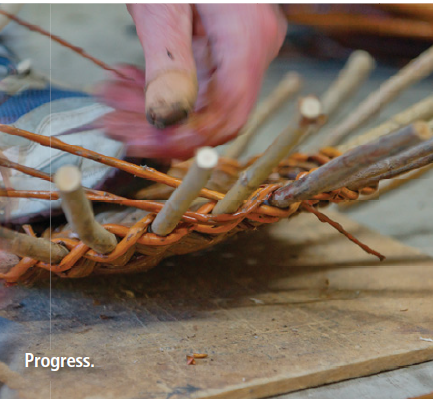

Here is the process when Mike makes a fruit basket which takes about two hours.

Mike gets down on one knee on the floor to weave the base. The process is called “tying the slath.” He places six sticks across and starts weaving, using two rods of willow. This stroke is called “pairing.” He weaves about 600 times, opening out the sticks as he goes. It is like making a spider’s web. He measures a 460 mm width, pulling rods up as he weaves to make a saucer shape. Once he has the desired size, he uses the secateurs to trim off protruding ends.

Mike takes 48 rods that are 914 mm (or three feet) long and inserts them evenly around the edges to make a “4 behind 2” border. He turns the base upside down and using a rod through the centre as a pivot, draws a neat 120 mm circle. He takes 24 stakes each 914 mm long and drives them into the base on the drawn circle, making spaces with the bodkin between each stake.

To start, he takes six stoutish 500 mm-long rods (about 20 inches in old terms) crossed over a second lot of 500 mm rods, then commences weaving using the tips of two very fine 1300 mm rods in a pairing stroke. He keeps joining in similar rods as required (tip to tip or butt to butt) until the diameter of the woven circle is about 460 mm.

As the weaving progresses, Mike pulls the rods up to form a growing saucer shape, trimming off protruding ends with secateurs and finally cutting off the protruding sticks after the 460 mm size is achieved.

Clipping ends

View fullsize

View fullsize

View fullsize

View fullsize

When the first two sets of three rods have run their course, Mike adds in a second two sets of three rods [butt to butt].

He continues the weave until the tips are reached then trims off protruding bits with secateurs. To tighten the weaving, he taps the willow down with a rapping iron. When the wale is fi finished, Mike uses a ruler to check for uniform height all around. Then he puts down uprights in a “4 behind 2” border. Mike Lilian explains that a wale is the name given to a type of stroke in willow weaving that involves working three or more rods at the same time and in a defi ned sequence.

“The result is a tight row of ‘ties’ rods, often three-to-six layers high, that holds other often-weaker side-weavings in position.

Fitness and strength

The photos show Mike Lilian working very forcefully—it is tough to be a weaver, pushing and pulling thick, stringy willow rods.

Ask him if his fingers and hands have natural strength or whether he has developed this, question if he needs to exercise, warm-up or uses robust techniques and he replies that he does no special exercises for strengthening. But Mike Lilian’s disclaimer about strengthening exercises is offset by his super-fitness.

“I do no special exercises for strengthening but have run or biked 80 minutes daily for the last 40 years followed by exercises such as 300 sit-ups and 100 press-ups…so I suppose that helps. Basketry is essentially sedentary and so the above regime has been rigidly followed so that I stay fit and healthy. When I spent time with the basket makers in Villaines-les-Rochers in France in 1994, I found most were idle and big-time smokers but fantastic makers nonetheless. I met only one fitness freak and we went on several runs together—a great way to get to know a stranger in a foreign land. I did get carpal tunnel numbness in both wrists and arms after 28 years of weaving, but minor surgery has fixed that.”

Coffins

The most unusual items Mike makes are the willow coffins. He began weaving them 12 years ago before he had a market but has found that they have become increasingly sought-after and sells about four each year. They are most often sold to people who plan to have a natural burial, usually in a native bush setting where trees are planted over the burial mound.

Natural burial sites are available in Wellington and Motueka, with sites in New Plymouth, Wanganui, Hamilton, Dunedin, and Christchurch under consideration.

One of his first clients was an elderly nurse who planned to keep her coffin in the lounge as a coffee table until she needed it for its designated purpose. Another had terminal cancer and ordered it for her imminent death.

A woman in the North Island ordered one for her husband. It was to measure 1720 mm long (5’ 7 3/4”) but Mike mistakenly made it only 1670 mm long (5’ 5 3/4”). She decided to keep the smaller one for herself.

He has several in storage for customers but is running out of space and says he will have to make other arrangements. He sells them for $1800 plus GST and takes ten days to make one, using about 20 kg of willow.

He notes that as coffins have to actually serve the function that they are intended for, he makes sure that they are super strong, using big sticks in the frame-work around which the weaving is done. “There are no prizes for a body falling through a coffin during the service,” he says wryly.