A workshop sale is testimony to a business and equipment from another era

By Bob Hulme

Photographs: by Adam Croy

I just love nosing around other people’s workshops to see what they are making and what gear they have, and I’ve just had the special opportunity to look at a manufacturing workshop that was about to be sold up and, as a bonus, learn about its history.

Macdonald Refrigeration surely has a place in Auckland’s heritage as a pioneer in its field. The factory has been closed for some time now and it has been hard for the family to let go of all the gear, but it is filling a lot of valuable space. Property leasing is the main focus for the business now and prospective tenants have been pushing them to make this building available in the sought-after suburb of Grey Lynn in central Auckland.

History of Macdonald Refrigeration

Refrigeration was in its infancy when Allan Macdonald decided to start his own business servicing commercial and domestic refrigerators. He had completed a fitting and turning apprenticeship at Winstone’s workshop in Auckland and had the entrepreneurial spirit to take on this exciting new field. It was 1938, the year his son Ian was born, that he took the plunge.

As refrigeration was new and there were no courses or qualifications yet available he had to learn as he went. He developed connections with American brands such as Westinghouse and Beech for servicing their products. Of course in those days most households still used a safe and refrigerators were regarded as a luxury, so there were very few servicing specialists. Being involved early in any field in its infancy is always an advantage, particularly when it has so much potential. Those early years would have been a struggle, with the rewards coming later.

They initially worked from premises at 1A Albany Road, Herne Bay, Auckland, concentrating on service work, but with the decision to add manufacturing to the business, they moved to Weld Street in nearby Freemans Bay.

Don’t plan on looking this street up though as it no longer exists. It was dug up and is now covered with buildings. It was a link between Napier and Union Streets. At that time there were neighbours, including the warehouses of Farmers Trading Co and Walker & Hall. There was also a row of small houses which the Macdonalds bought as they became available to use for storage. Their factory had 70 employees manufacturing domestic refrigerators as well as commercial units for butcher’s shops, hotels, hospitals, etc. Many of these were custom-made units, such as refrigerated window displays for butcher’s and fish shops.

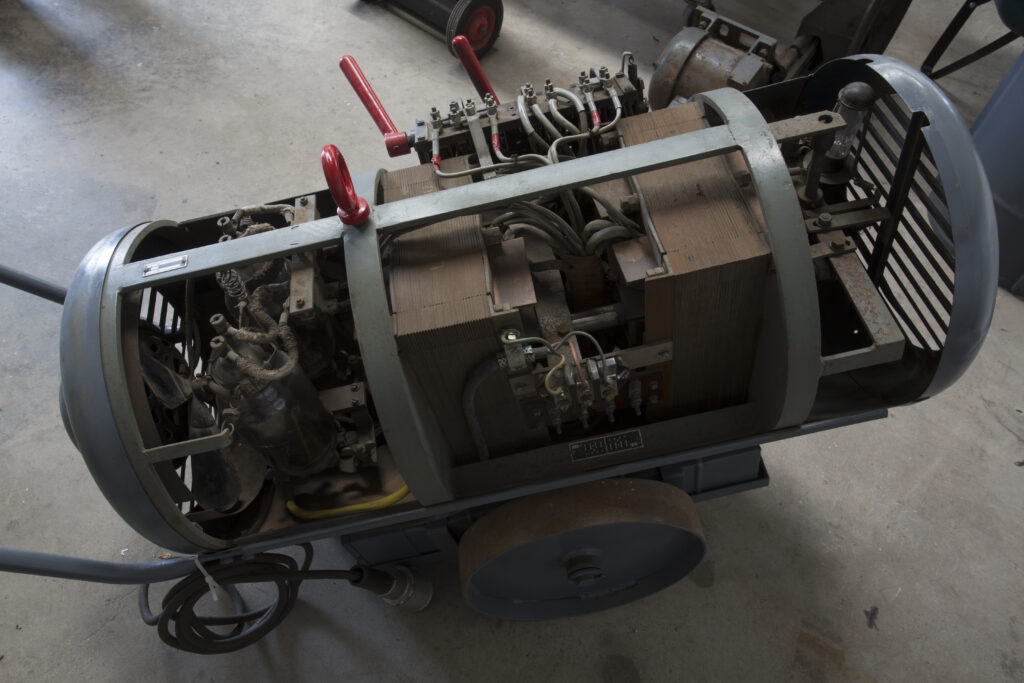

Vacuum pump

Still in its original shipping crate was an American-made Kinney vacuum pump that Allan Macdonald bought over 60 years ago for a project that he apparently didn’t get around to. Still it might come in handy one day! Notice in the photo that it came without a motor due to the American voltage being different to ours.

Importing materials

Being a manufacturer also meant being an importer of the materials needed to build the units. These included compressors, electric motors, and the refrigerant fluids. Organising shipments had to be coordinated with production. Often goods would be shipped to Australia first, then on to New Zealand. With labour strikes at docks on both sides of the Tasman occurring from time to time the coordination was often frustrating. An understanding bank manager was vital then, just as it is today.

Imported refrigerant gas was typically shipped in tall cylinders which they then decanted into smaller ones that were easier for their servicemen to handle on site. Typical refrigerants in those early days were methyl chloride and sulphur dioxide.

With refrigeration becoming more popular, especially for retail businesses, the need to travel outside Auckland to service customers was vital. Servicemen from Macdonalds were sent as far north as Kaitaia (Ian tells me he once went there and back in a day to do a repair job) and as far south as Hastings and Palmerston North.

Lathes

There was a row of three lathes – two Colchesters and a Logan. Now Colchester has always been a good brand and either of those would be welcome in anyone’s home workshop. They may be old, but the quality of those British made-machine tools lives on. The Logan would make a great replacement for a Myford. I am thinking about my own experience here when I bought a Myford for my home workshop but quickly found it was too small for most of the jobs I wanted to do. A Logan is a bit bigger, but not so big that workshop space is severely tested. Logans were never as rigid as a Colchester yet they filled that gap between Myford size and the heavier floor-standing lathes really well.

Famous clients

One of their customers was Adams Bruce who had a chain of shops that served delicious ice cream, chocolates and biscuits – at least they are the things I remember buying there as a kid. Each shop had a freezer for the ice cream of course, but Ian recalls that the Adams Bruce ice cream factory was in Collingwood Street, in Freemans Bay, and ice cream was sent to their shops on NZ Rail (NZR) Road Services buses. This was achieved by packing the ice cream in round steel cylinders that had a glycol hold-over tank with dry ice underneath – all wrapped in an insulated canvas jacket. Before the advent of courier companies most packages were handled by NZR road services buses.

After hassles with the Auckland City Council rezoning the area where their factory was in Freemans Bay and the council flip flopping on that zoning they decided to move. In 1968 they moved to a new factory they built in Richmond Road, Grey Lynn. They purchased the site from the well-known local Warnoch family, who had a soap factory next door, on a handshake deal – totally unheard of today. Staff numbers at this time were 42.

Every fridge has a story

I saw a number of examples of their domestic refrigerators in storage together with factory equipment. Some of them had a story behind them. I saw a red coloured fridge and a matching chest freezer. Ian related the story of the lady who bought the red fridge new from them and when it needed to come to the factory to be serviced, she followed the truck in her car to make sure that her beloved red fridge did not get scratched. When she passed away some years later the fridge and freezer came back addressed to Fraser Macdonald, Ian’s son, who had assisted the lady when her fridge needed remedial work. He had given such good service and she loved that fridge so much that she felt it should go back to the company.

Another old timer was a double-door fridge that I recognised as one similar to a model a relative of mine had years ago. This also had been bequeathed to the Macdonalds by a satisfied customer. Inspection showed that over the course of its life, all that it had needed was a new V belt for the drive from the motor to the compressor. Every other part was exactly as it was when bought new. Amazing!

Solid bench

It is not every day that you come across such a large wooden work bench made entirely from kauri. This one has seen some work and I did not appreciate the timber until Ian Macdonald pointed it out to me. I hope that someone buys this to keep as a work bench as I think it would be a shame to pull it apart just to sell off the timber.

Fill those freezers

The production of domestic refrigerators was eventually dropped as competition stepped up from other companies, as well as imported product, but MacDonalds established a niche producing chest freezers and were pioneers in the field. However, they were approached by a competitor, Bonaire, who also made chest freezers and were offered a deal to sell their products. The economics stacked up so they did the deal. This was a time when it was popular to buy a whole beast and store it in the home freezer.

Many Aucklanders will recall butchers like Albany Meats who sold wholesale and in bulk to the public. Ian tells me that they would sell direct from the factory and on the weekends people would often arrive with an animal carcass in the back of their car needing a freezer right away. They sold as many as 27 chest freezers per day at the height of that era.

However, commercial refrigeration was seen as the backbone of their business and eventually they concentrated solely on that market.

Manufacturing in NZ

Most of my own career has been in manufacturing in New Zealand and I am saddened to see so many businesses close their workshops and instead become importers of products manufactured in low-cost countries. It seems wrong that we allow our innovative Kiwi companies to suffer against imports of items from countries where their governments most likely subsidise them so they can overrun the competition. However I am heartened by the stories I do hear of New Zealand manufacturers making a go of it even in this environment. Just in the last week I have heard of a local manufacturer making rivets for export to China and another making fishing gear and selling successfully in many other countries.

Come on Kiwis, you can make stuff on home turf and if you can’t think of something clever to make just yet, at least try buying locally-made things in the meantime – the standard of living for all of us will improve. Ahh, I feel better now I’ve had my rant.

Metal-working machines

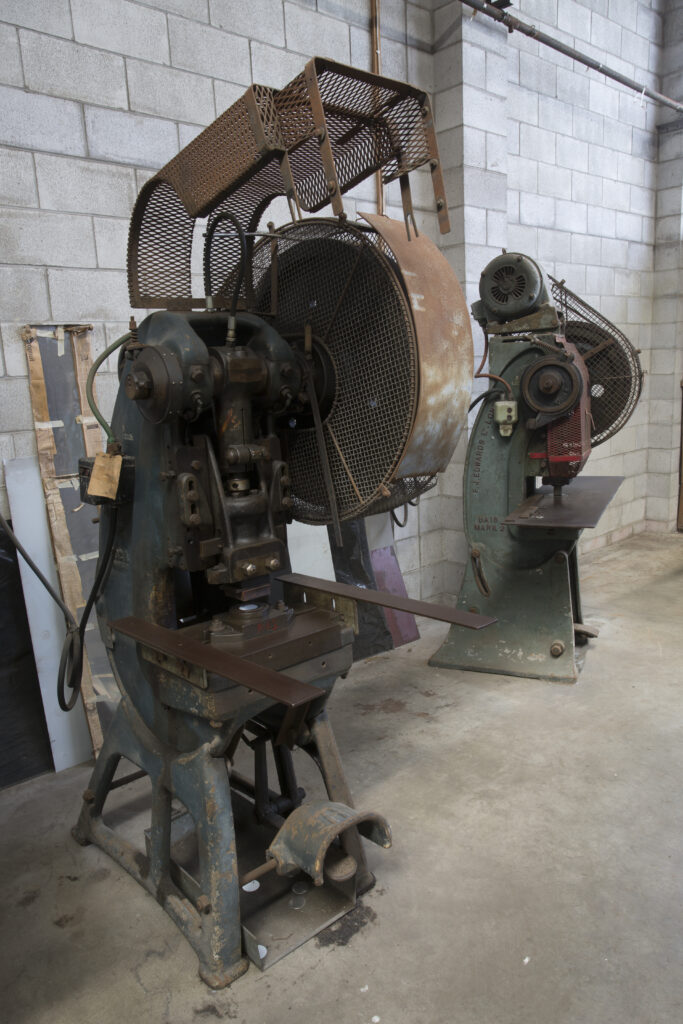

I felt like a kid in a lolly shop wandering around the MacDonalds’ factory. There is such a range of metal-working machines, I didn’t know where to start. There were folders, guillotines, a press brake, and power presses. Even a trusty Dyco drill press (brands such as Dyco and Tanner are very desirable today as they have proven that they are solid and reliable). I was especially interested in an old Philips arc welder. It can be set for AC or DC welding and on closer inspection I could see large, old glass vacuum tubes inside, presumably for rectifying the power. They told me that the welds it produced were wonderful and it is still in working order. Smooth finish and deep penetration were typical of the output. I have never seen one like this before – amazing.

All the machinery has obviously been kept in good condition and some appeared to have been modified to improve output. I noticed a guillotine driven by an old, but solid, electric motor and looked closer to see that it was a John Heine brand – the same as the two power presses that were there. Heine is recognised as one of the very best brands of presses. I have worked with this brand of power presses and they are so solid and reliable that they seem to keep going forever. Even their fly press was a John Heine!

Edwards is another brand that was once revered as a maker of top-quality equipment and the Macdonalds had an Edwards folder. This was a fine example of a folder made with a cast-iron frame, meaning that it has great rigidity.

There was another folder of more recent manufacture with a fabricated (welded) frame. I don’t want to give fabricated folders a bad rap as they do work quite well, but my pick would be the old Edwards. Another Edwards machine was a foot-treadle operated small guillotine – ideal for small jobs like chamfering corners on sheet metal items. Yest another Edwards machine was the press brake. No, it doesn’t break things, it bends them. The top blade moves down onto a fixed die block to bend the sheet metal between the blade and the die block. By changing the blade and the die block shape (the die block can be rotated to bring different forms to play) it is possible to create different bends or even radiused shapes.