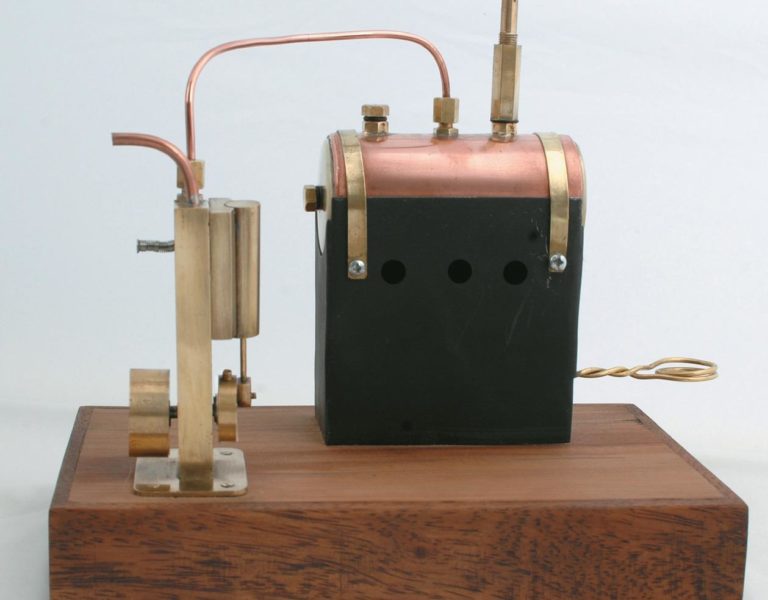

Black oxide finish

The particular process we are looking at in this article does not effectively alter the dimensions of the part as it etches into the surface rather than deposits on top. Black oxide finish is sometimes called parkerizing and it is common on components such as gun barrels because it does not involve high enough temperatures to cause distortion and there is no dimensional change.