Using the correct names and styles of common screw-thread fasteners

By Bob Hulme

There are so many types and kinds of bolts and screws that when you ask for the one you need, it is best if you understand the characteristics of the particular fastener. Then you can ask exactly for what you want. These characteristics are:

* Head type;

* Size;

* Thread form;

* Tensile strength;

* Finish.

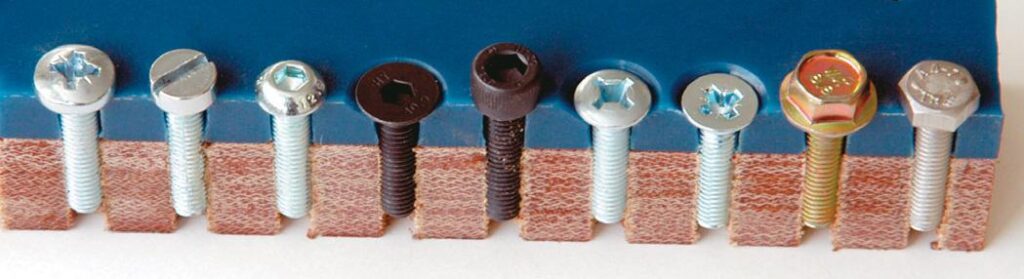

Head type

Different types of heads on different types of fasteners will suit particular applications and even specific trades. Hexagon head bolts are common on vehicles, for example, while pan head screws are more common in electrical equipment. A mechanic usually has his socket set close to hand where an electrician hardly lets go of his screwdrivers. Toolmakers and engineers tend to use socket head screws more and become nervous if they stray too far from a set of Allen keys. Hexagon head “bolts” change their name to hexagon head “set screws” if the thread goes all the way up to under the head. If fully threaded is what you want, you need to say that. Otherwise you will be supplied with bolts which have some plain shank between thread and head.

Philips and Pozi

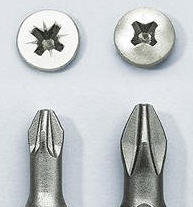

Countersunk screws and pan head screws are available in a variety of drives (i.e. the type of screwdriver you use on them), most commonly Philips, Pozidriv (Pozi), and slotted.

Philips and Pozi can look the same but there are subtle differences with the angles of the sides of the cross slots. To tell the difference between the two, look for the extra radial lines marked on the head of Pozi screws. The appropriate screwdriver makes life easier but there is now a screwdriver that works well with both Philips and Pozi due to some clever tip geometry. It is the SKG brand “all-in-one” screwdriver available at hardware stores or online at http://www.nutsnbolts.co.nz www.nutsnbolts.co.nz

Robertson (or square drive) is becoming more popular, but is generally available only on wood screws. Another type of drive for countersunk and pan head screws is like an Allen key recess but has rounded corners. Brand names for this are Torx and Sit. A Torx drive is similar to a six-edged Philips driver.

They are an improvement over the hexagon Allen recess because the rounded corners overcome the concentrated stress which occurs at the sharp corners of the Allen recess and can promote cracking. This becomes important where impact type power tools are used. A further variation is the security Torx drive which has a pin in the middle so that a special tool must be used although these are now more widely available. But when you see these heads on screws on such things as power tools, be warned that the manufacturers really don’t want you taking it to bits at home.

Cheese head

Cheese head screws are usually only available with straight slotted drive. They are used where you need a smaller diameter head than a pan head screw or where you particularly want to match other screws on a restoration project. They are found on older carburettors, for instance.

Socket head

Socket head screws are those where you use an Allen key to tighten or loosen them. Full and proper descriptive names for these are socket head cap screw, countersunk head socket screw and button head socket screw. Cup head (coach bolts) Cup head screws (often referred to as coach bolts) are a regular metal thread type with a nut, used mostly to secure wooden items.

The rounded head is smooth-looking, with no screwdriver slot or other form of drive but just under the head is a square section. Usually a hole is drilled through the wood and the “coach bolt” is hammered in so that the square section embeds itself into the wood. This stops it turning while the nut is being tightened.

Metric or AF?

Often you will see an advertisements for spanners or socket sets that offers as an alternative “metric and A/F” as if A/F means Imperial measurement. No. A/F means “across flat” or the distance from one side of a hexagonal head to the other.

Size and thread form

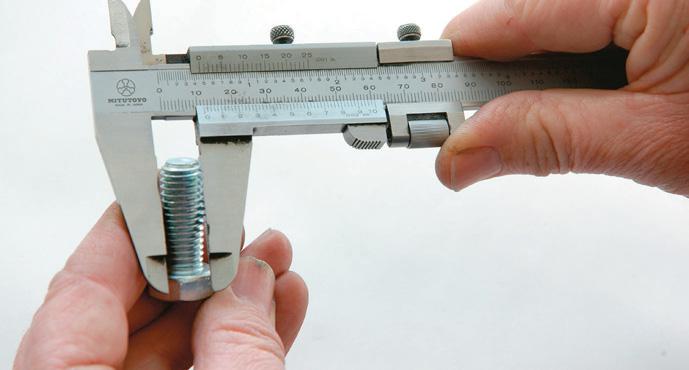

The three components of a bolt’s size are its diameter, thread type, and length. Now, metric or imperial? On a new project, you would be wise to select metric because they are more available. On an existing piece of equipment, better to identify what is there and stick to that. It will save swopping between metric and imperial spanners in future.

Measure a sample bolt carefully. With hexagon head bolts, there are often clues stamped on the head. An “M” will give the game away that it is metric as will the numbers “4.6”, “8.8” or “10.9”. Imperial bolts may have “BSW”, “UNC”, “UNF”, “G5”, “G8”, or “G9” on them.

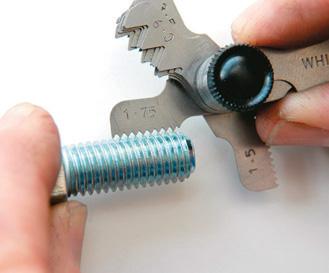

If there are no markings, you will need to rely on measurement. The essentials are a pair of Vernier calipers and a thread pitch gauge. Measure the diameter over the thread. If it measures from say 9.8 to 10.0 mm, it is most likely metric M10 thread as there is no imperial size close (3/8” =9.52 mm and 7/16” =11.11 mm). Use the thread pitch gauge to measure the bolt thread and check the data tables in your Engineers Black Book (available from The Shed, see the magazine or our online shop magstore.nz to order or an Internet site such as boltdepot.com (Fastener Info).

For example, a pitch gauge reading of 1.5 mm is M10 metric. Special fine pitch versions of M10 have either 1.25 mm or 1 mm pitch. To specify standard M10 metric thread, say just M10. For fine pitch versions, you must state the pitch as M10 x 1.25 or M10 x 1.0 mm.

If the bolt’s diameter is around 8 mm then it is not so easy to distinguish it from the imperial 5/16” which is 7.94 mm. In this case, use the thread pitch gauge and thread data tables to make the determination.

Length

To determine bolt length there is an exact measuring technique. The length of a screw or bolt is measured from the face or surface of the material being secured to the end of the screw or bolt. Therefore, the length of a countersunk screw length includes the head; others (the screws or bolts that sit above the material secured) do not include the head.

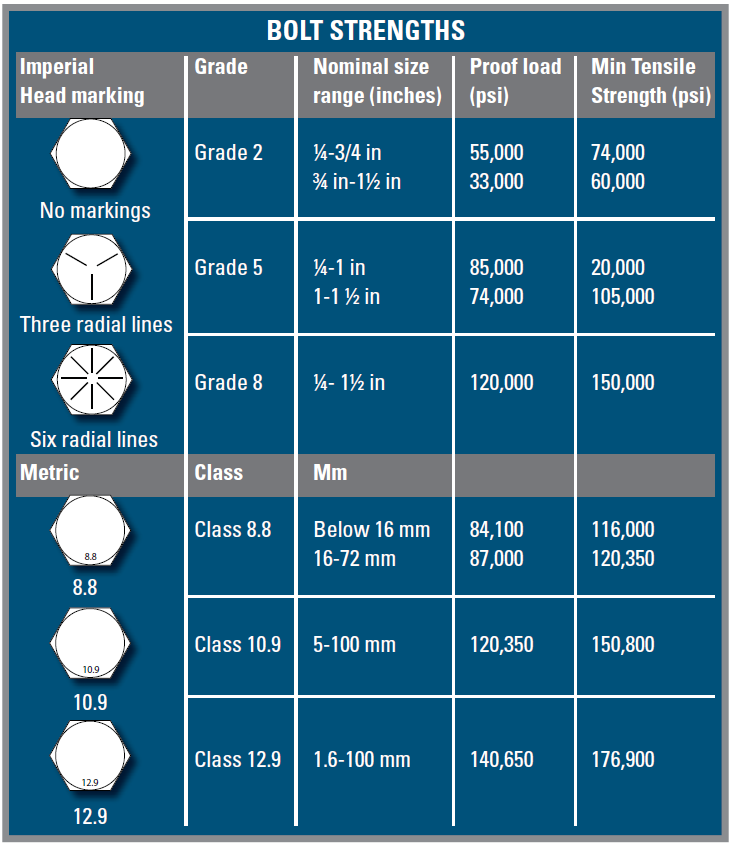

Tensile strength Hexagon head bolts have many strengths and as strength increases so does price. I have seen quite obvious differences in quality between international bolts supposed to have the same specification. Naturally, the low quality ones were the lowest price. I mention this so you are wary and don’t expect too much from cut-price outlets. My advice is to buy from a reputable specialist fastener supplier.

Mild steel is used to make the softest, weakest bolts and is quite acceptable in many applications. This is metric class 4.6 and imperial grade 2. In high tensile bolts, tensile strength relates to how much load a bolt can take that is trying to stretch it. The higher the tensile strength, the tighter a bolt can be done up without it permanently stretching or breaking.

Once a bolt stretches permanently and will not return to its original length when the load is taken off it is said to have “yielded”. Yield strength is specified for each tensile classification of the bolt as is the proof load.

Proof load

The proof load must be within a bolt’s elastic range so that when the load is removed, the bolt returns to its original length. The minimum tensile strength is what it will bear prior to breaking. For both imperial and metric measures, I have shown the stress loadings in psi (pounds per square inch) to make comparison easier.

Normally, metric loadings would be expressed in MPa (megapascals). High-tensile bolts are capable of greater clamping due to the higher torque that can be applied to tighten them. They will also bear greater loads in use. However, there are applications where higher tensile strength is not always best.

Where shock side-loading may be possible, it is better to use up to class 8.8 only. Higher classes are more brittle and could snap like a carrot. An example of this could be bolts for attaching a towbar to your car as there could be shock loadings when you drive over potholes etc.

Mild steel bolts are the best to use if you intend to weld them in place as a better weld will result.

Classes and grades

Metric bolts range from class 4.6 (mild steel) to 8.8, to 10.9, and then to 12.9. The higher the number the greater the strength. The same applies to imperial size bolts. Grade 2 is mild steel, grade 5 is the next up, then grade 8 and grade 9.

For a wide range of applications, using 8.8 or grade 5 bolts is good. The 10.9 or grade 8 bolts are used in particular applications where significantly higher strength is important. Socket screws are made to a standard 12.9 or grade 9 almost without exception. Nearly all suppliers stock socket head screws only in 12.9 tensile strength.

Imperial grades and metric classes of tensile strength are pretty close. For most purposes, grade 5 = class 8.8; grade 8 = class 10.9 and grade 9 = class 12.9. This is handy once you get a feel for what works best for you in either metric or imperial measures. Personally, I have only 8.8 metric and grade 5 imperial bolts on my workshop shelf as I would not want to use mild steel where it would not do the job. I would rather use a bolt that was too good and keep my shelf stock simple.

Other screws are made with fewer strengths than hexagon head bolts. Socket head screws are almost exclusively available only in 12.9 (or grade 8) strength. Coach bolts are generally only available in mild steel or stainless steel. Pan head and countersunk screws for use with a screwdriver are usually only mild steel.

Finish

If bolts or screws will have the benefit of an oil or grease coating, they can be bought in cheaper natural or “black” finish. But it costs a little extra to buy zinc-plated bolts or screws which don’t go rusty on the shelf and are always nicer to use.

If you often weld bolts in place you will want black ones as the zinc plating is a contaminant when welding. Commonly available finishes are:

* Black. Socket head screws are mostly supplied in black finish. They actually appear black rather than a natural steel colour because of heat treatment for strength. Mild steel bolts are a natural steel colour but are still referred to as black finish.

* Zinc-plated. A bright silver coating of zinc is electroplated on to the surface.

* Zinc-plated/gold passivated. By another process after zinc plating, a gold-coloured finish is achieved. Also called yellow chromate. This gives improved corrosion protection over just zinc plating as well as a classy colour. It is used extensively on bolts in Japanese cars.

* Galvanized. A zinc coating is applied by dipping the bolt into a tank of molten zinc instead of by electroplating. This thicker coating lasts longer in outdoor applications. Often used on bolts for the building industry. Used only on mild steel bolts because the heat used would cause high-tensile bolts to lose strength.

* Nickel-plated. This is applied by electroplating and is used on small screws that are common in electrical equipment. It stays a bright silver and shiny for longer than zinc plating. Not as commonly available as the other finishes above.

Stainless

Stainless steel fasteners are also readily available in two grades, 304 (A2) and 316 (A4). The 304 grade material suits outdoor use where there is no harsh environment such as salt spray or water. The 361 grade material is more expensive but has superior corrosion resistance and is OK in salt water and for equipment used for food preparation.

Rarer materials are brass, aluminium and titanium. These are used for their appearance generally and the latter two are for applications where light weight is also needed, such as on racing yachts.

Keep an eye out (or search for) on this website for Part Two of this series, Nuts.

Screw thread history

The invention of the screw thread is, in my opinion, right up there with the invention of the wheel. It is impossible to imagine everyday life without threaded fasteners.

Even in high-tech products, a close inspection shows the familiar hardware holding them together. It is believed the concept of the screw thread dates back to around 200 BC.

In 1586, the first screw-cutting machine was developed in France. This made screws that were reasonably identical and interchangeable; previously, hand-made screws had fitted only a particular nut hand-filed to fit. Standards for screw threads were established much later so in the meantime, equipment-makers decided on their own thread proportions and “mongrel” threads proliferated.

In 1841, Joseph Whitworth’s range of standard thread sizes was adopted as the industry standards in Great Britain. In 1864 in America, William Sellers’s paper on ideas for standard threads, different from Whitworth’s, was adopted by the Franklin Institute of Philadelphia, the forerunner of the American Institute of Mechanical Engineers. It took some time for engineers to change but in 1880 the standards were fairly universally applied, unfortunately with different sets in Great Britain and the United States, the two industrialised nations which used imperial (inch) measurement standards.

We still live with this legacy from the 1800s but ISO metric standards set up in 1947 have now been adopted by most countries. In New Zealand, we still deal with screws on equipment imported from North America as well as older machinery, so the fastener industry is not as simple as we would like.

When you buy any threaded fastener, it is important to understand what you need.