Lindsay Murray loves old hand tools, real wood and proper joints

By Nathalie Brown

PHOTOGRAPHS: DARRYL MAY

Sitting on the edge of a little paddock in the river mouth settlement of Kakanui, ten minutes’ drive south of Oamaru, is a ramshackle shed where Lindsay Murray creates things of rustic beauty.

The shed has a long history. It was built in 1875 as the house and shop of a nurseryman, George Packwood, who came from Scotland to plant and tend trees around the mill manager’s house in Kakanui.

When Lindsay, an artisan woodworker and sometimes blacksmith, took it over in 1993, the back wall had fallen off, half the roof was collapsing and the floors were rotted through in the living quarters. As far as Lindsay was concerned, it was perfect.

It had the remnants of the original dwelling: a kitchen with no running water but with a working coal range, and two other rooms which have served, over the years, as sleeping quarters and a sitting-cum-dining room. This is where Lindsay stays overnight when working on a major project. It also serves as temporary accommodation for visiting artisans and is currently home to Rolands Selis, a highly skilled leather worker.

Many sheds

“I’m a man of many sheds,” Lindsay says. “I build them, fix them up, make them bigger and change them. I spent a long time at the Red Sheds in Oamaru Harbour, building boats.”

It was his interest in boats that gave him his entrée into the work he has been doing on and off for thirty years.

“It started about 30 years ago when I was 23. I bought a book called Skiffs and Schooners by R D Culler and it has been my bible ever since. At intermediate school, I used to win prizes in metal and woodwork. After school, I travelled and then worked in the freezing works, married and had kids but was very conscious I wasn’t feeding my creative side. So, following the instructions in my boatbuilding bible, I made a good little skiff in the family house here at Kakanui in the 1970s.”

He left the freezing works and teamed up for a while with Dave Armour, who is famous in North Otago for his artisan woodworking skills. And that was when Lindsay really began to take what he calls “a giant leap sideways.”

Hand tools

“There’s an artist in most people, but to bring that out, you need to slow down and work at your natural pace. Mine is quite social, which means I might only work a concentrated six hours a day”, he says. “There’s not much that technology can offer that appeals to me. I have a preference for doing all my finishing work with hand tools.”

Taking pride in the detail of your work, appreciating the beauty in something you have created, having a sense of aesthetics that informs everything you do in your workshop, is at the core of his philosophy of the ”giant leap sideways.” It also encompasses his concern for the environment and the need to minimise the impact of his carbon footprint.

“For the last five years, I’ve spent eight hours a week behind the wheel of a vehicle travelling to and from jobs, picking up supplies and the like. It’s time to think and act locally. I need to generate my work and do it out of my workshop or within the confines of the village. I believe we all need to look at what we’re doing in that context and also reassess our attitude towards money. We need money to survive but as soon as the money becomes the key objective of work you’ve lost your vision in life.”

Lindsay and Dave restored a horse-drawn wagon, and Lindsay did the ironwork for it. “That’s when I started blacksmithing. I was entirely self-taught out of books, and Dave gave me the confidence to carry on and develop. He took me from someone who could do things well to someone who could do traditional and weird woodworking things like slating a roof and steam bending.”

Ketch woodwork

Lindsay then went up to Whangarei and met Steve Kafka, who owns a boat called Evohe, a 26-metre steel ketch most often chartered by companies undertaking scientific research throughout the world and by television documentary makers working on natural history programmes. For ten years and more, Lindsay has been the principal woodworker on the Evohe, spending a month or so every two years doing repairs and maintenance. He originally fitted out the galley, bathrooms, cabins and wheelhouse, and made the chart tables and cockpit seating.

His next stop was Port Chalmers, where he spent a year working on small boat building. “I signed up for a boatbuilding course and ended up co-running it. The course had great outcomes – each student built their own boat and took it home. Out of that came work with a furniture-maker there. Shortly after that I talked to my ex-wife and got the family batch at Moeraki where I built a traditional workshop in board and batten, one-and-a-half storeys high. That’s where I built the fishermen’s punts that operate off a marine railway.”

Celtic culture

The next four years were especially formative for the itinerant artisan. “It was very good for getting things in perspective, and that’s where I discovered my Celtic culture. My grandfather influenced me in this. I used to wear a kilt long before it was fashionable for men in Oamaru.”

It was also where he learnt to appreciate the Celtic skills of hand-eye coordination. He learnt that the Celts were great artisans; they taught the Romans about chariots, and they were artists at the forge.

In 1996, he met a woman who had been trained in many artistic and artisan techniques from the age of five. They planned to work together in the Kakanui shed.

“I had just set up business out of this workshop and also bought a cottage in Kakanui. I married Antonia and within weeks she was diagnosed with advanced cancer. I gave up everything to do with woodwork, sheds and boats and looked after Antonia with the help of friends for four years before she died in 2001. Then I gave up on everything in general for a while,” he says.

“Eventually, I got a job through friends to build a dental surgery in London with Dave Armour’s son Dugal. The ex-pat New Zealand client couldn’t find builders in London who could do the job in the time-frame required. She wanted a coordinated theme with custom-made office furniture. The walls had to be lead-lined to cope with the X-rays. That got me back on my feet again and back into sheds.

“In the last few years, I’ve been working as a self-employed carpenter, subbing for a team of builders. I’ve just given them my notice and as of Christmas this year I’ll be back in this shed full-time and into artisan work: traditional boats, furniture, blacksmithing. – anything that doesn’t involve MDF and custom wood. It has to be real wood and proper joints.”

And this is where his work with John Baster comes in. John arrived in Oamaru two years ago so that he could spend more time with his family, but ended up commuting to Wellington for a couple of weeks each month.

Weta workshops

In a 20-year career, he has been a gun-for-hire as a model maker in architecture and film. He has been involved with Weta Workshops for 14 years, working on The Lord of the Rings among other projects, and has just finished work on Prince Caspian in the Chronicles of Narnia series.

“I’ve been increasingly interested in developing myself outside that role,” he says. “Lindsay and I share a love of boats, which is how we met. I’ve been exploring creativity and the role of the craftsman. Ultimately, this shed is a learning environment where you can push yourself because you set the standards. It’s an environment where I can expand my skill base. It’s different from film work, which is high-pressure. This is where I learn new things.

“At the moment we’re working on a coracle for the race coming up on Sunday 2 December in the Oamaru Harbour. Lindsay and I worked out how to build an English-style Ironbridge coracle, and we’re now undertaking our first commission. Separately to that we are building two 20ft-long (six-metre) Irish canvas currachs for a community project. We egg each other on to do new things.”

Meanwhile, Lindsay is feeling confident about the prospect of working professionally from his shed. ”I’ve made a living out of here before building bay windows, furniture, boats, gates and the like. The overheads are really low – the average power bill is $50 a month. There’s no downtime and it’s healthier and cleaner – I don’t work with tanalised wood.

Coracle capital

“We built half a dozen willow coracles and two Ironbridge coracles, which are sawn lathe and canvas-covered. That work should continue because Oamaru is becoming the coracle capital of the southern hemisphere. The coracles John and I are building today are lovely things – all hand-eye coordination. When you’re sawing wood, you often don’t need to draw a line – just think straight. A hand tool is just an extension of your hand, like an artist with a brush or a pencil.”

The tool cupboards, boxes and drawers in Lindsay’s shed would make an industrial archaeologist weep for joy. There are scores of devices for every woodworking purpose and he has made several of them himself with scratch stock and old saw blades.

He operates from a replica of a traditional German cabinetmaker’s work bench, which he made himself, complete with tail vice. He also has a replica of a 17th-century journeyman’s fold-up work bench used for planing wood and several journeyman’s tool totes together with the tool chests that are the apprentice carpenter’s ultimate project.

Favourite tools

One of his favourite tools is the Stanley No. 45. Nickel-plated and with a rosewood handle, it was originally advertised as a joiner’s toolbox in one tool. Among other things, it creates tongue-and-groove patterns

Lindsay identified the Stanley No. 45’s advantages over a router: “A router is noisy, dusty and demands electricity, and there’s no soul in it. The results are just not pretty. There’s such a distinct line that you know it’s not hand-made.”

He uses power tools to break down and prepare timbers, then takes up hand tools for the rest of the work. Most often, he does hand-scraping for finishing as he doesn’t much like sandpaper. Lindsay and John coined the phrase “over-stroking” which to them means too much sanding and buffing to take out all the tool marks. A “good job” leaves the maker’s marks intact.

He also uses the electric grinder for putting a point on a bolt and for coarse work, but all tool refinement is done on a hand grinder.

Adzes

The tools are many and varied: Adzes and hatchets for creating knees, a boatbuilder’s plane for internal and external curves, a little brass bevel that he made at age 18, and a boat nipper made by his son William. There are caulking irons and mallets for sealing seams and tightening up the planks on a boat. There’s a steam box to make wood pliable.

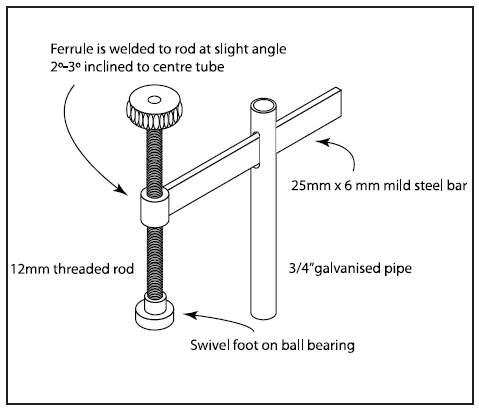

“People don’t know about tools like a holdfast,” he says, demonstrating its use by inserting the rod into a hole in his metal workbench and clamping a plank to the surface. Sure holds fast! Or a dowel plate for making hardwood dowelling rods. Most people today buy a machine to do the job.

He makes mortise and tenon joints with a chisel. Then there’s the tool for taking internal measurements. For certain applications, he says, it’s much more accurate than a ruler. He makes curves and compound curves with an ancient Irish tool that looks like a bow. A plank line can look beautiful or ugly, especially on a boat, which lends itself to artistry.

He sourced all the tools from second-hand tool shops over the past 30 years. “Good second-hand tool shops are hard to find now,” he says. “People now mostly buy through the internet, and most tools are hanging on walls as decorations.”

The passion for hand tools is part of the great leap sideways, as is the blacksmithing. He is still setting up the forge and plans to make hinges, pintles, latches and catches – all lightweight architectural forge work to go with the boats, doors, gates and cupboards he makes in the shed.

CORACLE IN HISTORY

An early mention of a coracle-like vessel is in the Old Testament in Exodus, when the mother of Moses floats her baby. “But when she was no longer able to hide him, she took a papyrus basket for him and sealed it with bitumen and pitch. She put the child in it and set it among the reeds along the edge of the Nile.”

The National Coracle Centre in Wales notes that coracles (from the Welsh “cwrwgl”) have a history dating back thousands of years. The coracle was originally covered with animal skins, and in some countries, they are still made this way. Modern vessels are now skinned with calico, which is waterproofed using a bitumastic paint.

Stanley Joseph writes in Craft a Coracle that only a few changes in coracle construction have occurred in the course of 2000 years and these have varied regionally. One involved the use of sawed laths, as in Ironbridge, instead of split ash or willow branches in the lattice framework, and also ash lath in the making of the gunwale, instead of plaited hazel or willow. The hide covering was replaced by flannel, made waterproof by tarring or pitching. This substitution probably took place around the time flannel began being made from the wool of mountain sheep, which became an important local cottage industry in the late 16th century.

Coracles are paddled, or more correctly sculled, not to the stern but rather over the bow using a figure-eight stroke. Paddling to the side, as one does a canoe, sends it in circles.