Photographed and edited by Adam Croy

An article featuring David and his skeleton clockmaking appeared in Issue 79, July/August 2018 of The Shed

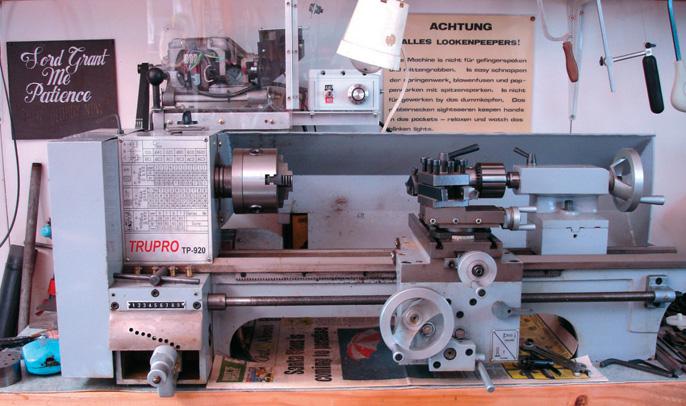

Aucklander David Curry shares with us his shed where he makes skeleton clocks, stationary engines, tools and more.

Photographed and edited by Adam Croy

An article featuring David and his skeleton clockmaking appeared in Issue 79, July/August 2018 of The Shed

I purchased all the brass sheet and rounds required, plus a main-spring, brass bolts, and screws of the various sizes needed.

Now where to start on the clock?

I carefully read and followed the order and instructions of the book. If the instructions are not adhered to, many anxious moments and frustrations will follow.

Here is a step by step guide to making a stylish 36mm small clock, inserted into a 50mm sphere and placed on a tapered stand which you can make easily with your woodturning lathe.

Enjoy making these clocks to sell or just for the pleasure of pursuing a hobby. For this clock, the author used pohutukawa for its density of colour and rich finish.

Ken England has been fixing clocks as a hobby in his Whakatane shed since the 90s.

Repairing a clock is not just a case of pulling it to bits, replacing parts then re-assembling, he tells me. “Everything works in sequence and has to be timed.”

He is a member of the New Zealand Horological Institute but was never a clockmaker by trade. What makes Ken “tick” and has given him the necessary clock-repair skills is the engineering know-how already in his background, a knowledge of how to machine parts, manufacture, and silver-solder.

The Shed magazine is eclectic, informed, and always fascinating. Aimed at those with a few tools and perhaps a few clues: this is the magazine for real sheddies.

Packed with ideas, projects, advice, and peeks into other people’s sheds providing inspiration, ideas, and techniques, or just for the sheer enjoyment of the sheddie’s endless inventiveness, The Shed is the project enthusiast’s bible.

Sign up here to The Shed monthly email newsletter for exclusive reader offers.

Sign up here to The Shed monthly email newsletter for exclusive reader offers. For signing up, we’ll send you a free copy of The Shed, just simply put your postal address in the form.