In The Shed Issue 79, July/August 2018, we head to Wellington to document Shea Stackhouse making a small knife from Damascus steel, fondly known as a Puukka (that’s Finnish for small knife). While we are there we hang around to meet some knife fans who receive knife making advice from Shea at one of his regular knifemaking classes.

Whanganui is where we meet master birdhouse builder, Steven Price. Steven went from building practical houses for people to building amazing houses for birds before Enrico Miglino introduces us to an Arduino-type board, BBC micro-bit. In this issue, we build a houseplant moisture monitor.

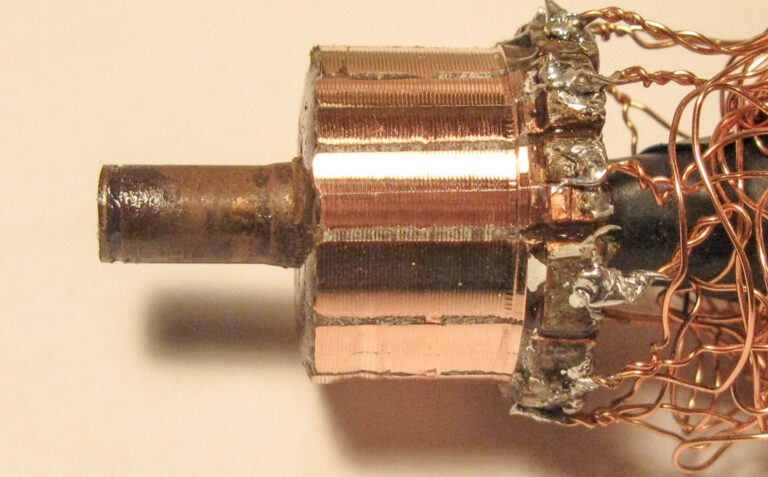

Raf Nathan shows us how to build some simple iPhone speakers from native timber that make great gifts and we discover the world of spectacular glass artist, Carmen Simmonds. Carmen makes her own glass, creates pieces from it as well as giving tuition to those eager to learn this fine craft. Lachie Jones follows the install of a flat-pack kitchen by Gary Hatfield and gets some solid tips and advice for us sheddies and, if you enjoy the art of clockmaking, you will be blown away by the work of Aucklander, David Curry. Not only does David make skeleton clocks from scratch, he makes the tools to manufacture the parts! As well as stationary engines electronic ignition systems and more.

Landlocked Piopio is where we find Max Laver Marine making unique boats and canoes from Macrocarpa, David Blackwell discusses the essentials and beauty of a good square and Geoff Merryweather forges a set of sturdy loads skates for moving heavy pieces of machinery around your shed.

Jude Woodside completes his strong and sturdy-as lathe bench by making and fitting steel drawers and Mark Beckett warns us of the dangers of cheap USB chargers. Part 5 of our series on 3D printing sees Enrico explore the features of the 3D software, Tinkercad, that make it perfect for newbies and we go on a journey with Ritchie Wilson, to save money, get some history on and learn all there is to know about sharpening stones and sharpening tools.