By Jude Woodside

Photographs Jude Woodside

A RECYCLING ETHOS AND A BIG DOSE OF INGENUITY HAVE RESULTED IN VERY EFFICIENT GAS-BOTTLE STOVES.

Stuart Guy with his house truck

You can’t do that! You’ll kill yourself!” said the hippy to the gypsy as he began slicing into into an LPG gas bottle with a four-inch grinder.

Sixteen years ago, self-styled “hipsy” Stuart Guy found himself spending his first South Island winter in an un-insulated house truck. Back then second-hand woodburners were plentiful but far too large to fit anywhere in Stuart’s tiny 1962 Bedford truck. So the resourceful engineer decided to make his own from what to him seemed the perfect vessel. Disused LPG bottles are well suited to being repurposed into fireplaces, braziers and woodstoves. His stove was soon finished and test fired in the wee truck on a load of tea tree and pinecones. “Just the bomb!” was the unanimous verdict from the assembled members of the Original Gypsy Fair—a group of musicians, entertainers and craftspeople who have been travelling around New Zealand for more than 25 years. Since then Stuart has welded up more of this version of his now well-known woodstove “Fat Max” than he can count. “It’s been interesting,” he says. “Over the years people have tracked me down and asked for my stoves after finding how well they warm their friend’s buses and trucks. I’ve improved the doors and the venting system, added new features and generally turned them into a recognised part of the New Zealand alternative living scene.” “ There has even been an occasion when he spotted photographs of his stove work in the interior of a New Zealand gypsy house truck featured in a German lifestyle magazine—the translated caption read: “Every feature of this home on wheels is a tribute to the owner and his circle of skilled artisan comrades.”

Stuart Guy’s gas bottle stove range

Expanded range

Stuart’s life as a travelling hippy/gypsy took a turn in 2004 when he purchased a property in Waihi but he still shows the resourcefulness and ingenuity that he learned on the road. Instead of buckling down and getting a real job, he has now expanded the range of recycled gas bottle stoves to include three sizes. The largest is now the most popular—Mighty Max. This one is made from two 9 kg cylinders welded together giving more volume and a more ergonomic cooking height. While Stuart was travelling he played with another fuel option— waste engine oil. The naysayers stuck their oar in again: “You can’t do that! What about the smoke?” they asked. But he persisted and developed an oil-vaporising device that can be retro-fitted to any of his existing stoves. Stuart’s videos on his Blazing Stoves Facebook page show that the stoves reach an eye-watering 380℃ with a perfectly clean exhaust emission. They burn around one litre of waste oil each hour and seldom need to be cleaned as there is no solid fuel. Stuart gets his waste oil provided by a local trucking company which otherwise has to pay to have it removed. Stuart provides two wetback units for his stoves—a simple U-shaped booster for an existing hot water system, or a full copper heating coil that has a volume six times larger and heats water quickly for spas and bush baths with no fuss on demand. Brilliant when coupled with the waste oil fuel!

Work in progress includes a Fat Max stove and the newly designed Mighty Max with an oven attached

Stove prototypes

Stuart has tools for every eventuality including a commercial sewing machine and eyelet press from a previous career as a canvas worker and an industrial compressor (he does his own sandblasting). Toward the rear of the shed there are woodworking machines and an industrial drill press. Stuart’s stove fabrication bench has both MIG and Arc welders as he is working with varied thicknesses of steel. Hanging on a large nail at the end of the bench is a fat wad of well-used patterns for all components of the various stoves that he now produces. “It takes so long to nut out the first prototype for each stove that I have to gradually claw back some time by speeding up the build on each one that I do for other folk. This and the fact that almost every part of the stove is recycled means that I can get a standard stove to the end user for a lot less than they could have one made for.” He has kept all the stoves at one price for some years now—$300 gets you a stove that would otherwise cost in the region of $1100.

The basic stove is simply a gas bottle that has an expired test date. It’s cheaper to buy new than retest gas bottles so bottles that can no longer be refilled due to an expired test date are simply discarded. Stuart removes the filler valve and fills the bottle with water removing any unspent gas. The bottles are often left for several weeks to ensure that residual gas has fully dissipated.

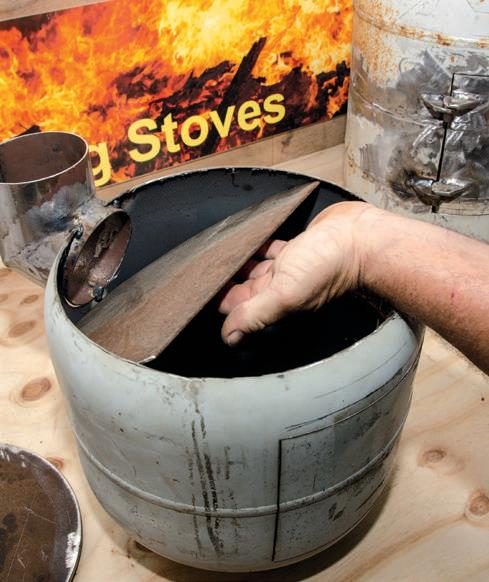

Fitting the secondary burner plate. Note how the plate deflects the heat onto the front half of the stove top making that the hottest part.

(right) The gas bottle prepared for removal of the door

The build

He cuts off the top portion of the bottle completely to house the 6 mm steel plate top. Then he marks out and carefully cuts out the door. Stuart prefers to use an abrasive disc rather than a plasma cutter. Without completely removing the door he welds two hinges in place and then finishes releasing the door from the body of the bottle. He welds pins in place inside to house the grate which is made in two parts to enable it to be inserted through the door. He cuts a hole in the top opposite the door for the flue and welds more pins in place to support a secondary burn plate that diverts the heat onto the stove plate and enables any unspent gas and ash to be burned before entering the chimney. Trial and error over the many stoves already built has eliminated the issues of “blowback” caused by earlier flue design, cracking of welds and leaky door seals. The two components that eventually give up the ghost on all stoves are the grate and the secondary burn plate which Stuart now has ready to dispatch if they are required.

Welding the hinges before completely removing the door.

(right) The hingeswelded in place.

Supports for the grate in the base of the burner.

(right) The grate in two parts for ease of insertion

The bomb shape of his stoves and the fact that pressure vessels are made from Corten high-tensile steel means that the actual body of the stove is likely to be free from distortion or corrosion for decades. There is a good number of hours in the making of each stove and a fair few cutting discs get turned to dust ensuring that the weld lines and door openings are as tight as possible. Stuart is currently working on a heater with attached oven heated from the flue passing through the back of the oven. The oven model is based on his Mighty Max model to create a convenient working height.

The profile of the stove with the oven showing how the ovenattaches to the stove.

Stuart using a router to cut the new groove to fit the staves of the drum.

(right) Stuart showing the oven cut to fit the flue.

Stuart demonstrating howthe Rocket Stove feeds.

As the efficiency of the design was embraced around the globe, people living in colder latitudes discovered that the stove had amazing draw and could pull exhaust gases a long distance while harvesting all the latent heat that goes to waste in traditional wood-fire designs. These Rocket Stoves were appearing in publications across the world attached to huge thermal mass cob mud-brick benches around the walls of eco-friendly homes—all well and good if you have access to lots of mud and straw and own your own home. Stuart’s design allows the firebox to be attached to other thermal mass, but the stove itself contains nearly 70kg of firebricks to provide a significant thermal mass that will continue heating the home for up to four hours after the fire is extinguished.

The ash pan of the Rocket Stove usually has very little ash given how well the stove combusts.

(right) The damper on the Rocket Stove.

The Rocket reaches extremely high internal temperatures approaching 1000°C. For this reason the horizontal burn tunnel is ceramic lined and the vertical, secondary-burn chimney is heavily insulated with pearlite. These stoves are suitable for cooking, heating and water heating. Perfect for your off-grid project. Stuart encourages home engineers with a cold shed to build one of his stove designs for themselves or, alternatively, to purchase one ready to use. He has all the flue components, heat shields and hearths needed to fit one effectively and works closely with each purchaser to ensure that their stove is fitted in a safe manner and that optimum flue efficiency is achieved.

Note: None of these stoves are BRANZ approved for use in a house so building consent for installation will not be approved

A Rocket Stove spaceheater installed.

The Mighty Max has a device in the base made from an old brake drum which helps to hold the heat to vaporise the waste oil dripping into the interior.

The burnerflue is in the centre.

Fat Max showing the stove set up to burn.

The smallest stove:the Mini Max.

Real rocker

Customers for the stoves are almost universally the alternative life-stylers who Stuart clearly has strong links to. Aside from still sleeping in his self-built Bedford house truck when he is working at his property there is evidence around the rambling garden of his efforts to reuse, reduce, recycle and generally live a lifestyle that has minimum impact. Stacks of wooden pallets and cable drums await recycling into funky furniture and planters for the garden and there is an outdoor bath set into a deck that looks suspiciously like it too

is made from recycled pallets. A now-redundant, self-built wind turbine is pushed up into the shed’s roof trusses while another of a different design is under construction on one of his three work -benches. One of Stuart’s latest projects is turning old cable drums into rocker recliners. He disassembles the drum and cuts a new groove for the staves to turn it into a seat. He is finding it difficult to source the larger cable drums that are suitable for adults but has no shortage of smaller drums that make ideal children’s rockers

Stuart Guy lives in Waihi in his house truck when he is not selling his wares at farmers’ markets in the Hauraki Coromandel area.

His Facebook page Blazing Stoves hasmore information on his work