Father-and-son team build a grunty offroader

By Greg Jorey

Photographs: Greg Jorey and Jude Woodside

Over the last couple of years, my son Kurt and I have built a few basic go-karts which not only gave him a taste of very basic engineering, but also allowed us to pile up valuable hours of quality time working together in the shed. This new project had a bit of a twist to it as, this time, my son was the chief designer and engineer and I was relegated to labourer. Like all the previous projects, he let me fund it.

The plan was to build a small one-person off-roader that would suit a 12 to 13-year-old through to an adult. It was to be powered by a 300 cc quad engine we had inherited and, most importantly, it had to be safe for those brave enough (or silly enough) to climb into it. With this in mind, we ventured into the shed with our engine, seat and some old quad wheels and chalked a life-size plan on the floor. Other than trying to keep the look in proportion with the wheel size we were using, our only restriction was that the overall width had to be around 1.5 metres to fit on our trailer.

Engine mount

Placing the engine behind the driver made the wheelbase and overall length too long so we agreed that the engine would be best mounted next to the driver in front of the rear axle. Our engine is a little unusual as it has the drive sprocket on the right-hand side of the engine. Most Japanese engines drive from the left side. It doesn’t matter which side of the frame you mount the engine, as long as the chain and rear sprocket are within the frame area. This reduces the possibility of damage from objects passing between the frame and wheels.

The position of the engine also enabled us to easily locate the swing-arm hinging-point in line with the drive sprocket on the engine This would give an even tension on the chain regardless of how much rear suspension travel there was. It did, however, raise a few safety issues like how to isolate the driver from the engine, exhaust and chain, while still retaining a strong, safe frame. Our design overcame both these issues by having a tube frame partition between the driver and the engine that structurally mirrored the outside framework and was panelled with 1.2 mm aluminium.

Plan change

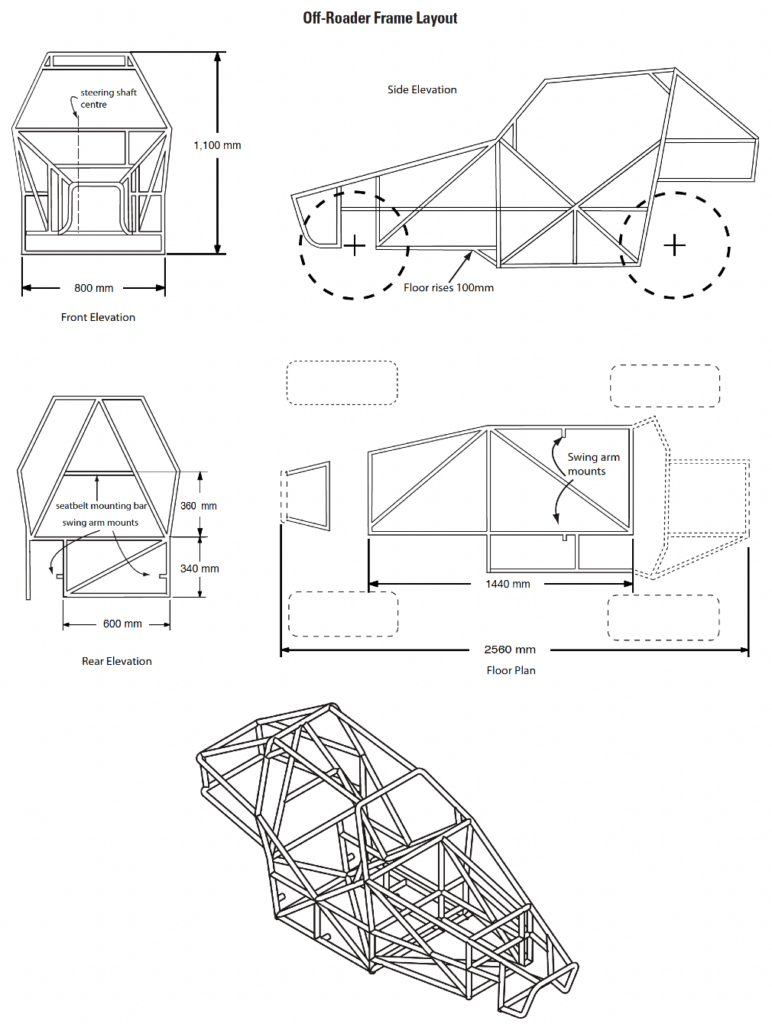

Our chalk drawing on the shed floor was rubbed out and changed a number of times. But it was an ideal way of highlighting things like the frame being too wide at the front which meant the wheels hit it before a reasonable steering lock was achieved. It was also an easy way of working out where to mount the seat in relation to the steering wheel and pedals. The chalk drawing was then scaled down and transferred to paper, elevations were added and, presto, Number One son had designed and drawn a reasonably complex piece of machinery. Not bad for a 14-year-old. Some of the finer details, such as shock mounts, steering shaft mounts, pedal mounts etc, were not shown on the plan as we needed to procure these items before nutting out how to mount them. The elevations looked in proportion to the wheel size and the drawing was good enough to work out how much steel we needed and what bends we required.

Parts

The next step was to make up the parts list and spend some of Dad’s money. When building something like this, it is so much easier to source everything you need before you start any fabrication. If you don’t have the exact components you require, you could end up spending a lot of time and money altering something you have already made. Take the time to plan and procure before you start production.

The frame is made out of 32 mm x 2 mm exhaust tube and, because we don’t have a tube bender, we drew an actual size drawing of each frame component that required bending and made a visit to the local exhaust shop.

The only other steel used was 50 mm x 6 mm flat bar, 25 mm x 3 mm flat bar, 30 mm solid round for the axles, 16 mm solid round for the steering shaft and 40 mm x 40 mm x 3 mm box section. It is surprising how much steel actually goes into something like this. In this design, we used more than 46 metres of 32 mm tube, five metres of 50 mm flat and four metres of 25 mm flat.

To help keep the base of the frame square, and any matching left and right angles the same, we drew a life-size plan on ply and used saddle clamps to hold the tube in place. The floor where the seat is mounted is 100 mm lower than the floor where the pedals are so our ply had to be multi-level. The ply is a very cheap makeshift jig which we also used when making our rear roll-bar assembly. This keeps your work square and reduces the chance of your work warping when welding.

Steering

Steering is very similar to a go-kart except, in our case, the driver is sitting to the right of centre so the steering shaft is not centre to the front axle. This meant that one steering arm (or tie rod) ran from the steering shaft to the right front wheel and then a drag link ran from the right front wheel to the left front wheel. This was to keep the steering geometry in check ensuring both front wheels turn at the same angle at the same time.

The tie rod and drag link are made of 10 mm solid rod which we threaded at the ends to take standard 10 mm female rod ends. Because the drag link was so long, and a possible weak point in the steering, our local Hydraulink branch put the drag link inside an equivalent length of 10 mm internal-diameter (ID) hydraulic tube and swaged the two pieces together. The end result was a super-strong drag link.

The steering shaft is mounted top and bottom by spherical bearings in 2-bolt housings. We paid extra attention to the upper bearing mount because it endures a lot of stress as the driver supports the upper body weight via the steering wheel.

We had two goes at the steering ratio with the better of the two being almost a 2:1 ratio. At the arm on the spindle, we have 125 mm from the kingpin centre to the centre point where the outer tie rod end is mounted. The drop arm at the end of the steering shaft is 60 mm from the centre of the steering shaft to the centre point where the inner tie rod end is mounted. Admittedly, given the size of the tyres we are using, we are probably on the limit for this type of steering and would suggest that a car rack-and-pinion is probably a more suitable option.

Race seat

Because early teens to not-so-early adults were going to pilot this thing, we chose a generous-sized fibreglass race seat with slides and seat belt holes to accommodate a 5-point harness. One area that you shouldn’t skimp on is driver safety so always choose a good, well-made seat and a good three inch-wide (76 mm) 5-point harness.

We are fortunate enough to know someone who has a lathe and he knocked up our rear axle out of a piece of 30 mm solid round. He cut an 8 mm keyway the length of the axle so we could slide our brake disc and sprocket to any position we require. This is also handy if we ever re-power with a different engine. We can simply slide the sprocket along the shaft to line up with the new drive sprocket.

Rear axle

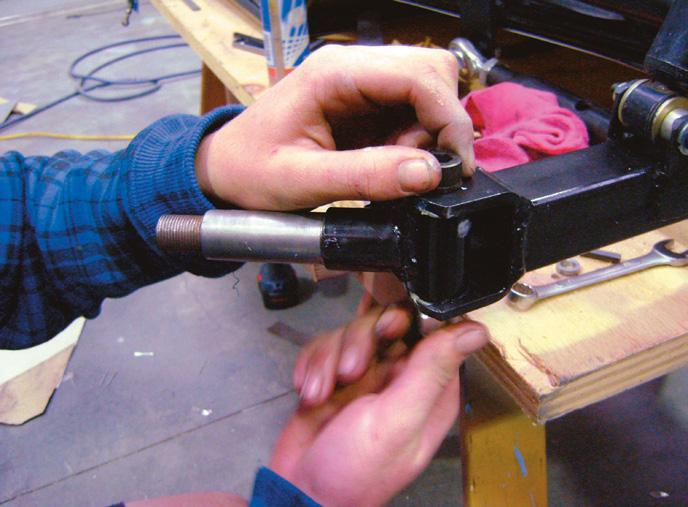

The rear axle is mounted by 2-bolt bearing housings (Catalogue FY506M) with 30 mm ID spherical bearings to a swing arm made from 40 mm x 40 mm x 3 mm box section (DSC0014 JUDE). The shape of the swing arm will vary depending on the sprocket and brake disc diameters. The swing arm is mounted to the frame by two 25 mm ID spherical bearings in two bolt housings and these bearings obviously fit onto 25 mm solid pins that are very well mounted to the frame. The rear sprocket is off the quad bike the engine came out of, so all of the gearing is exactly to manufacturer’s specification.

Chain tension

The chain had to be replaced as the quad one was too short as we discovered after our first test run. We should have incorporated a chain guide and an easy-to-adjust chain tensioning system as a new chain stretches very quickly.

The front axle is made of 40 mm x 40 mm x 3 mm box section and is held in place by five category-O agricultural top links. Four top links work like trailing arms and the fifth is a panard rod which stops the axle moving from side to side. The “Ds” at each end of the axle are standard, off-the-shelf, trailer leaf-spring hangers and put the kingpin vertical or at 90 degrees to the axle. The adjustment in the top links allows the kingpins to be laid back to fine-tune the steering.

The front spindles or stub axles are a standard item you can buy from most ATV-type trailer rim stockists. The axle is way too long for this application so it is cut to a length that suits the rim. The off-cut is bored and welded to the stub for the kingpin to go through. It should be noted that there is a lot of force put on the spindles when cornering. It is advisable to get these professionally welded if you only have a small, single-phase arc or MIG welder.

Shocks

Suspension is simply just motorbike shocks and, unfortunately, there is a lot of trial and error involved before you find the right shocks to suit your ride. Things like spring tension, mounting angle and mounting position on the axle or swing-arm play a huge part in how the ride responds to the suspension. Make sure you field-test your suspension before making any changes as you will be surprised how much axle-travel you will get from what seems to be firm suspension. I am sure there is some way of calculating the ultimate suspension set-up and, if you spend enough money, you will end up with the perfect ride. We just tried a few old motorbike shocks and adjusted the tyre pressures a bit to give us a ride that was kind on the back and the wallet.

Braking

Braking comes from a single disc on the rear axle. We used a disc and rear master cylinder off a Chinese quad and find it more than capable of locking up the rear axle. For a lot of trouble and expense, you could go to four-wheel braking, but I think the advantage would be minimal.

Electrics

We had the wiring loom off the quad that the engine came out of so it didn’t take too much to nut out the electrics. Of course, Number One son wanted toggle switches instead of an ignition switch, and the neutral and reverse lights were a must. The battery was mounted above and towards the rear of the engine which is basically where it would have been on the quad so we had no issues with the length of the loom. All of the ignition system was mounted on the aluminium just in front of the engine and then finished with an aluminium cover to keep the mud, stones and water off.

Brain work

For a father and son (or daughter) team who like spending time in the shed tinkering with automotive or engineering-type projects, this one is a beaut. At times, smoke was coming out of Number One son’s grey matter as he worked out things like pedal ratios, gear linkages, steering ratios etc, but, all credit to him, he nutted it out. When we had finally finished the project and were standing back admiring our work, Kurt said to me, “Dad, I think I used every tool you own on this one.” And I think he was right.

This sort of project involves planning, tech drawing, engineering, mechanics, electrical, spray painting and sheet metal work. It gives a young person with an engineering or mechanical interest a huge head start and confidence boost, especially if their chosen career is in a related industry.

For those who think something like this is a little too complex for a shed project, we are just a couple of blokes with a MIG welder, a few hand tools and a desire to create something from scratch. A word of warning, though. If you have the same desire to build something like this it will set you back over $7000, so kids ask your parents first.

* For an earlier go-kart built by Greg Jorey and son Kurt, check out “A kart for the kids and Dad,” The Shed, Jun/Jul 2008.