The September/October 2022 issue of The Shed, No. 104, has something in it for every sheddie.

Our cover story this issue is on a couple of blokes who are collectors and restorers of stationary engines of all different types and sizes. Tom Gregory and Gary Norton have got the bug bad and both find it hard to go past a stationary engine of any era and any fuel type. Spending time with Tom and Gary as they describe their addiction to these soldiers of past years will surely convert many readers to the joys of stationary engine ownership.

“There is something endearing, almost comical, about the chugging, spinning, and belching machinations of vintage stationary engines.

“These early exemplars of internal combustion technology sit like naked towers of component parts jutting incongruously from oversized flywheels; everything in plain sight. Sometimes fuel tanks, exhausts, filters, and pumps look as if they have been bolted on as an afterthought. While function definitely trumps aesthetics, design-wise their rounded lines still have a charm of their own.”

Build a classic workbench

We have the second and final part of our How to Build a Classic Workbench series, and in this finishing-up article put a vice onto our bench that we built in the previous issue. This project is undertaken for The Shed by John Shaw from The Centre for Fine Woodworking in Nelson.

“Now it’s time to get working on the vice. What we have on our hands is a beautiful little project of reasonable complexity that demands accuracy, uses both hand and machine skills, and is incredibly satisfying in both the making and the using.”

Learn lost wax casting

Lost wax casting is a real asset to your workshop arsenal. We met David Reid in Issue No. 103, and in this issue he walks you through how to do your own lost wax casting so you can cast bronze like a pro. David demonstrates the making of the ceramic shell and crucible followed by burning out, or ‘losing’, the wax.

“The process involves washing and drying the sprued wax sculpture and the button cup crucible then coating them both twice with slurry one and fine Molochite 50-80 or black magnetite. Ensure the layers are completely dry in between coats.”

Building a kitset log house

No one needs to be told how expensive it is to buy or build a house these days in New Zealand. So what to do? Well, one enterprising sheddie from Glenorchy came up with a cunning plan to buy a kitset log house online from a US supplier. How hard can that be, right? Mal McKee shares his build tales with Shed readers.

“So, you want to build your own house — yahoo. Hopefully it will be as rewarding as it has been for me building ours, but hopefully with substantially fewer dramas.

“Just to keep it interesting, my wife and I ended up doing things a bit back to front: garage, then honeymoon, another garage, then marriage, then kids, and now the house!”

Tales for Makers

Our electronics guru Enrico Miglino is getting deeper into his ambitious project Tales for Makers. In part two of this adventure story based on fictional technologies, Ray looks for his son Tommy, who disappeared after fiddling with an old parking meter.

“An intelligent drone impersonates the dominating technology he meets. I think that any maker at least once in his life would spend some time thinking about doing some hacking on this fascinating world. The second part of this project, which I present in this issue, will inspire all those makers fascinated by these futuristic flying objects.”

Off the grid

Our enterprising Murray Grimwood really enjoys finding items that he can repurpose or rebuild. This issue is no exception, as Murray stumbles across the ultimate Thermette. What’s a ‘Thermette’ you ask?

“Hereabouts, we’ve been heading in the wood-fired outdoor-cooking direction for a while (see The Shed Issue No. 98, page 52) and a pair of Thermettes have played their part; a traditional one and a stainless tank of a thing — which I hid while we went away sailing, forgot where, and lost for a decade, but that’s another story. Then, a couple of months ago, at an auctioneer’s, I spied what, at first blush, looked like the Wurlitzer of all Thermettes.”

Custom garden trellis

Andrew Broxholme is a very, very busy sheddie, but two things that really annoy him are wasting materials and buying products that you can easily make yourself cheaper and better. Making your own trellis is a perfect example. In this article, Andrew shows us just how easy it can be to make your own.

“You can buy pre-made trellis screens at places like Mitre 10 or Bunnings but I won’t pay that much for something I can make for a fraction of the cost. The other problem with commercial products is they typically come in only a few standard sizes that can’t be modified easily. I can make panels whatever size I need.”

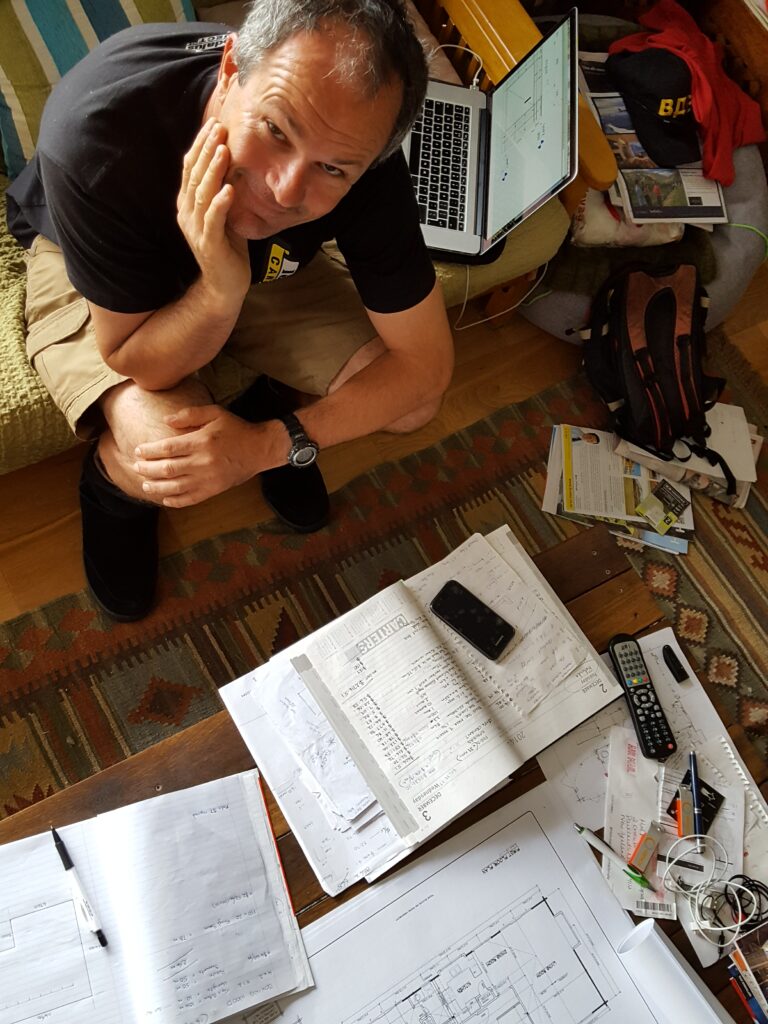

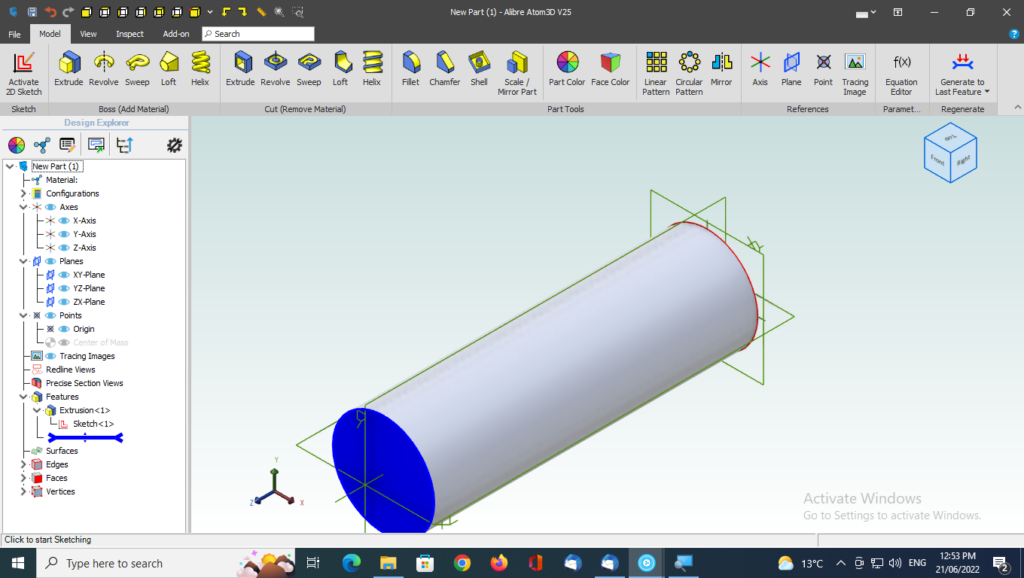

Alibre software tutorial

Occasionally you need to get a part made at a specialist workshop and the whole process can go terribly wrong if you don’t have clear diagrams that the manufacturer can use as a guide. Alibre is perfect for this task, but how do you use it? Bob Hulme walks us through how to use this dynamic software.

“Why do I need to learn this? I suppose that you don’t need to learn this stuff, but it is so much fun — why wouldn’t you want to learn how to do it?

In today’s environment, where digitally controlled equipment is now common, businesses that provide services such as cutting, folding, and machining are receiving digital drawings rather than the printed drawings that were still the norm until a couple of years ago.”

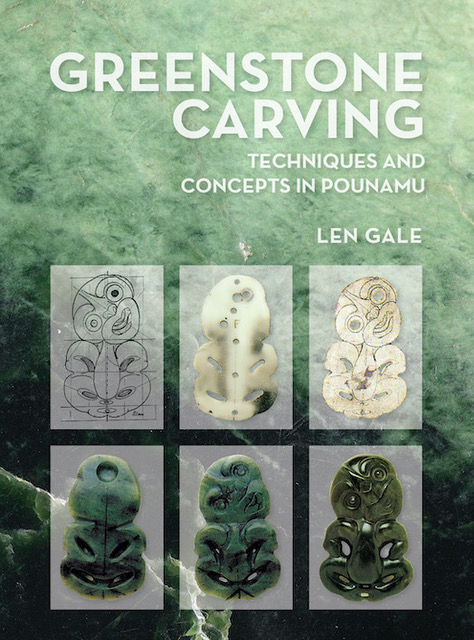

Book review

Greenstone Carving — Techniques and Concepts in Pounamu

By Len Gale

Greenstone carving is a popular pastime for many sheddies. The goal of this terrific book is to show anyone inclined to give greenstone carving a go exactly how to get started and get proficient.

“Greenstone Carving begins with a couple of short chapters on Māori greenstone carving and the traditional forms.

Author Len Gale’s admiration for Māori achievements with simple hand tools is easily understood when you appreciate how hard greenstone is and how much effort it takes to make a finely crafted tiki — even when using diamond-studded grinding wheels revolving at thousands of rpm.”

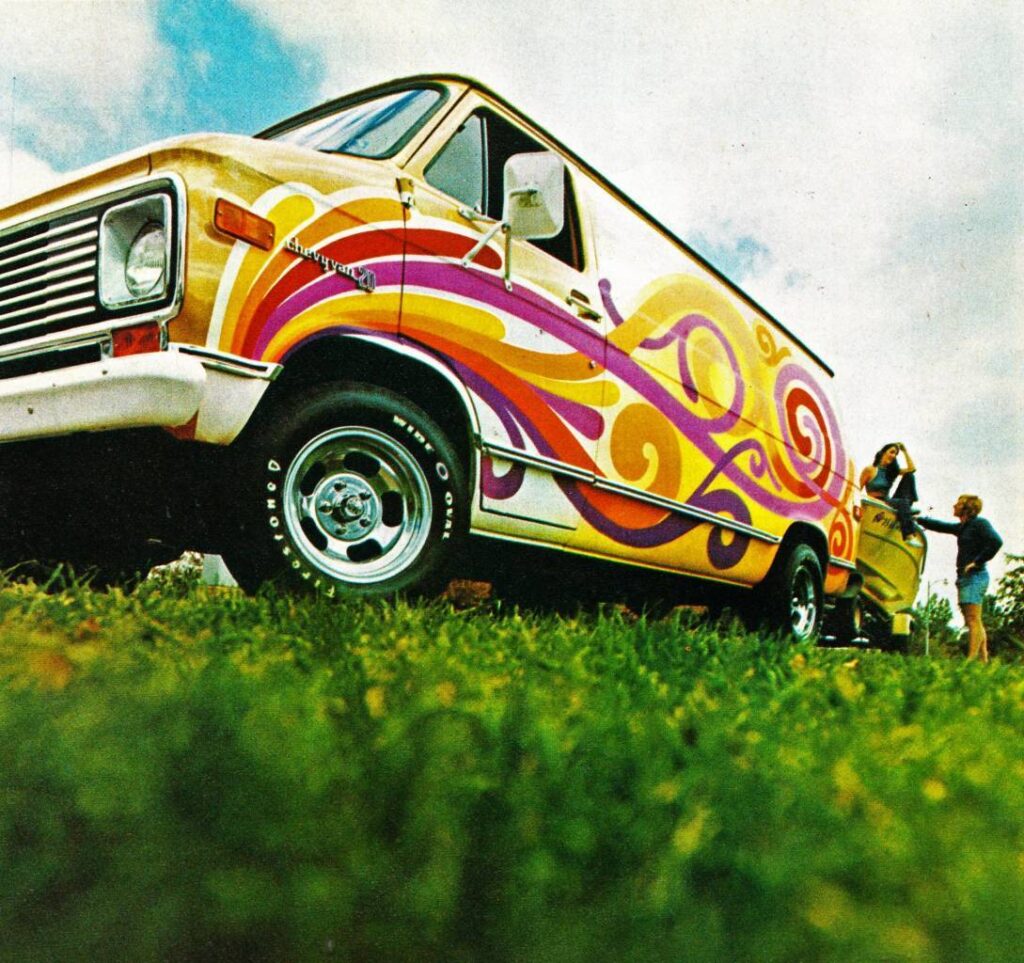

The Shed shrink

Our resident mental-health coach Mark Seek reminisces about the ’70s — a time of flares, cool vans, and what was hip. Oh, and some of his mates weren’t that nice to him either.

“I have been known to avoid people who ride or drive certain bike brands and car brands. According to my dear wife, my thinking is bordering on prejudice. I had no idea I was prejudiced. I was chatting with a mate the other weekend. We were discussing motorcycles; as usual, we both agreed that certain bikes from the past warranted the title of ‘cool and classic’, but only a certain few Japanese bikes.”

Time-honoured craftsmanship

Watchmakers are getting fewer these days as many folks no longer bother with timepieces that aren’t actually some sort of digital screen. However, Mainlander Reg Horner is a skilled watchmaker in the time-honoured tradition who restores and repairs all types of, mostly vintage, watches and clocks. But Reg also has another side to him: he adores vintage cars and has a truly unique collection of Marmons.

“It’s almost a cliché of black-and-white spy movies: a man wearing a trench coat and a trilby checks his watch. He realises it has stopped. He winds it up and glances up at the local clock tower, to set the time.

“Back then, all watches needed winding and keeping town clocks accurate was an important civic duty. However, that whole scenario is passing into history.

“It’s a curious business, considering the art of the watchmaker. When most of us were growing up, the trade of watchmaking, if not as common as plumbing, carpentry, or motor mechanics, was not at all rare. Everyone had a mechanical watch, and there was a ‘watchmaker’ employed at most of the bigger high street jewellers to clean, adjust, and service watches and, of course, clocks.”

Back o’ The Shed

This issue and every issue, The Shed founder Jude Woodside closes the magazine with what he’s up to in his shed and in his new life. This time, the treatment of Julian Assange has really got him worked up and he worries a lot about what his persecution may mean for us all.

“This is a bad outcome for freedom of the press. Silencing and intimidating the press, and making journalists conform, is the first step in any autocratic regime and it signals the end of your own rights and freedoms.

“It is the job of the press to hold governments and those in public power to account. To this end, journalists can protect their sources and they have a certain license to question and even cajole those in power.”

To purchase a copy of this issue or to subscribe, head to our online shop.