A family affliction

With the genealogy of the five generations of South Island engineers in the family, Ross Hayes thinks nothing of rebuilding Land Rovers for fun, family and farm.

Ross Hayes was 17 when he bought his first Land Rover. It was road-legal, but that was about it. It turned out that it was cosmetically covering up a huge amount of rust, so it wasn’t going to make the long haul.

Ross bunches his lips. “I got a bit disheartened and decided that if I couldn’t trust anybody to sell me a good one, I’d build myself one.”

He bought a 1954 short wheelbase Series 1 Land Rover in December ’96, just after he turned 18. “I paid six hundred bucks to a guy out of Naseby called Owen Rawcliffe, who’s since passed. I brought it back to Oamaru through the Danseys Pass and set to pulling it to bits.”

He bought workshop and parts manuals from the UK and a set of Whitworth sockets and Whitworth spanners and got stuck in.

The Mistress, as he came to call this ‘54 Series 1, spent five years, three months in the workshop – 6000 hours – while he pulled it to bits and rebuilt it.

His idea was to start with a chassis, and everything that went onto the chassis was either rebuilt or brand new. It was hard to get parts back then in the 1990s.

To purchase a copy of this magazine, head here to our online store.

A great idea made real – the Auckland Library of Tools

Why buy a new tool for just one job when you can borrow all you need from a tool library? Less waste, less storage and all fees covered by a library membership. It’s a win-win.

Ever find yourself standing in Bunnings or Mitre 10 looking at laying out two or three hundred dollars for a tool that you absolutely need to get a job done, but will quite possibly rarely or never use again?

If you’re in Auckland, put your wallet away and head over to the Auckland ‘Library of Tools’ on Newton Rd. A few years ago, newly hatched and full of aspiration, ‘ALOT’ got a small mention in a The Shed piece about makerspace ‘Hackland’, with which it shares premises. Now, in 2025, the library is a winner.

Co-founders Amanda Chapman and Tom Greer and friends manage an ever-growing team of volunteers serving a steady stream of members coming in on Tuesday and Thursday evenings and Saturdays, checking out an impressive range of items – 2026 of them at current count.

Building a gantry crane – how to construct a workshop heavy lifter

When I was asked to clean out my late father-in-law’s workshop, I knew that it would not be an easy task.

My father-in-law was not one to suffer from an iron deficiency, and his workshop was proof of the amazing amount of equipment you can fit into an otherwise ordinary, prefabricated metal garage.

The main problem involved how to get the machinery out of the workshop and onto a trailer for the 3 1⁄2 hours drive to Auckland, then offloaded at the other end. This machinery included a lathe weighing around 750 kg. There was poor access to the workshop, which had a single roller door and limited access inside. Facilities on site included a small engine crane and a small orchard tractor with a front-end loader. All the construction and moving had to happen over the Christmas holidays.

The solution was a portable gantry crane that could be taken up north in parts, assembled on site, be low enough to fit through the roller door, but could be raised inside to an adequate height to lift the machinery onto the trailer.

3d printing

Bob Hulme has another project for your Alibre Atom 3d program. This time, he demonstrates how to make a camera shroud to help you see your digital camera screen on sunny days.

“I like those viewing screens on the back of cameras that save having to squint through a little eyepiece, but I find that when using the camera on a sunny day, the screen is quite difficult to see well.

My thanks go to Murray Grimwood for his article in The Shed issue 115, where he showed several projects he was working on. Among them was a sunshade shroud for his camera that he had made from a standard electronics box. “Just what I need!” I said to myself.

My camera has a screen that swings out and rotates. A feature that I use a lot. So, I needed a shroud that moved with the actual screen and independently from the camera body. I also wanted to look into 3d printing, so the answer was to make a design using my Alibre Atom 3d program, and the digital file would be easily fed to a 3d printer. This is an example of how useful a 3d CAD program can be at home (or in your shed).”

AJS motorbike restoration – part 4

Part 4: electricals, upholstery and fuel tank. The road to restoration never runs smooth. Peter discovers that his knowledge of electronics is severely tested, where patience and perhaps some self-improvement is required. You could call this series of articles ‘Zen and the Art of Being a Sheddie’.

“About two years ago, I took a 500 cc single ‘AJS’ motorbike (theoretically a 1952 model 18s) out of 50 years’ storage as a partly dismantled machine. A retirement project.

I use quotation marks around AJS because the machine has turned out to be a real bitser with at least one Matchless part (half crankcase with the engine number). The year 1952 has also turned out to be more of an average than exact; bits range from 1947 (gearbox) to an at least 1956 (carburettor).

Some months into intermittent work, I thought that I could write about it for The Shed, and here is the fourth article describing what I have been doing on this restoration project.”

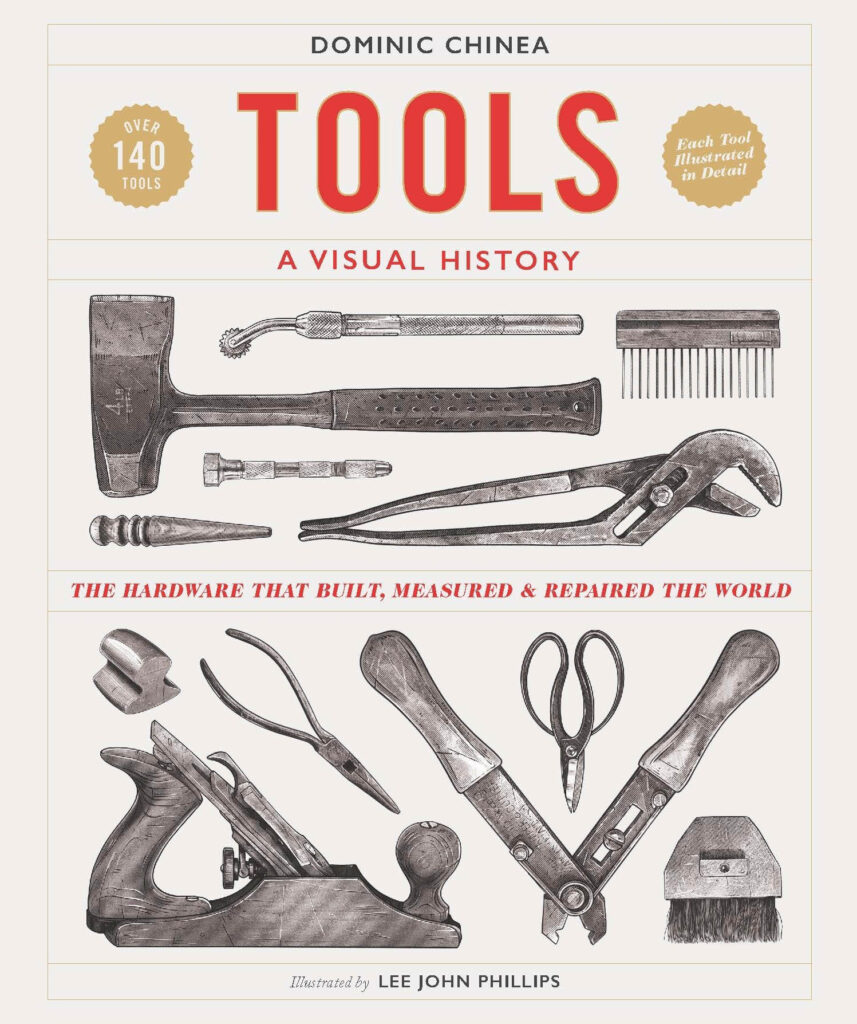

Book review – Tools: A Visual History

By Dominic Chinea

Dominic Chinea lives in England and gets up early on Saturday mornings to trawl car boot sales, looking for tools which are either attractive or potentially useful. He has written a book about a selection of his tool collection, researching the history of the tools and their makers. He has been most fortunate to have secured the services of Lee John Phillips to draw each of the tools he has selected in the book.

Tools: A Visual History has been out for a couple of years, but is still available. The price of $48 seems to me to be exceptionally good value for such an attractive publication.

Dom Chinea is the metalwork person in the BBC’s The Repair Shop. He’s the one with the thick black beard. His high profile is undoubtedly the reason he was able to get the book published, but it is a really interesting read and has been put together with a great deal of skill and care. He writes in a chatty manner, describing the use of the more uncommon devices, how they have intersected with his own life and what companies are particularly associated with that type of tool. The illustrations are simply outstanding.

Building My Dream Shed – Part One: Foundations

She’s a hard road to find the perfect shed. However, The Shed magazine founder, Jude Woodside, is giving it a bloody good nudge.

“Like everyone else, I have been constantly frustrated with working in cramped workshops. Even relatively large areas, such as my last one, succumbed to the pressure of too many tools, too little space.

When I moved again, I was determined to build the shed of my dreams. I started designing at 200 square metres, but cost quickly whittled that down to my current 160m2.

I found a useful design tool online, most of the shed suppliers have them, this one was particularly good (although it was from a manufacturer in Western Australia), and I was able to try a series of different scenarios (https://royssheds.com.au/) which I could print off and get quotes for from local suppliers. The tools don’t expect you to have any CAD experience, it is very intuitive, and you can get a good perspective on your future shed inside and out, along with a variety of custom fittings such as doors, windows, etc.”

Arduino basics 102: Errors

Our Arduino Wizard shares some thoughts and solutions to dealing with ‘Errors’ and provides guidance on how to display to the user that something has gone wrong… somewhere.

“In the last few issues, we’ve covered a range of subjects, with ‘Display’ in the last issue, The Shed 120. These have all assumed one thing – that there are no errors and everything is working correctly.

Anyone with any experience knows that things don’t always go to plan, and having a contingency or recovery option is useful, although some might say essential.

It’s no different in the software world. Errors could be caused by hardware failure, programming, or something the user does that was totally unforeseen. I’ve seen software writers comment, “Why would anyone do that?” when a user crashes the software program they wrote. My answer is “Because they can”, and we know that quote for ‘assume’, which is appropriate when you expect everyone else will have the same workflow and thought pattern as you did.

This article hopes to provide some thoughts and solutions to dealing with errors and indicating or displaying to the user that something has gone wrong.”

Off the grid – building a bike-based smoothie maker

Murray asks himself, “Why am I off the grid? Why do I fix rather than replace?” The answer is simple: he’s getting himself ready for a post-oil world.

“Every now and then, a column called ‘Off the Grid’ needs to ask: Why? Why go off-grid? What is the driver? And the repercussions?

This little offering was triggered by my better half asking me if I could build a bike-based smoothie maker after she had watched one being used at a recent event. Sure, no problem – but apart from teaching lateral thinking, what will it achieve? Will we really end up going that way?

I spent the ensuing days pondering.”

Mini truck restoration: My retirement project (part 2)

As the project reaches its conclusion, Coen decides he needs more grunt in his mini truck, but there are supplier problems aplenty to annoy and frustrate.

“To briefly recap.

Having recently retired, I decided I needed a project to slow down, if not mitigate, the sedentary lifestyle that overtakes many of us in retirement. Consequently, I purchased a small 1968 Daihatsu Hi Jet 4-wheel drive truck to refurbish and take me to remote places in nearby bushland where I like to walk my dog.

Those of you who have read my first article will be aware of the various travails that beset my project. One of these was the small two-cylinder motor that originally came with the little truck.

To cut a long story short, I eventually managed to rebuild it and get it running, complete with new pistons, a repaired head, etc. Although it ran as it should (albeit briefly), I soon discovered that it isn’t really up to the task, as any sort of headwind or hills have me reaching desperately for the lower gears! That’s okay on the quieter backroads, but unfortunately before I get to them, I have to spend some time on a two lane highway frequented by huge logging trucks moving their loads between a timber mill and the local woodchip port as well as, other sundry, trucks, cars, milk tankers, and the like.”

The Shed Quiz No. 3

You’ve got a shed, and you know how to use it – but do you really understand how everything works? Test your sheddie knowledge here

New reader competition – the ‘Versatile Shed of the Year’

Do you have New Zealand’s most interesting shed? Whether it’s the cleanest, most cluttered, epic man cave or simply one-of-a-kind, we want to see it! We love them all, and now it’s your chance to show off your shed and win.

How it works:

We’ll select the top five sheds from all the entries.

These finalists will then be showcased on Facebook, and the public will vote – the shed that obtains the most likes and comments wins!

Woodwork project: Unintended Consequences

Having successfully built a stylish kitchen table, Nigel reckons he should now have a crack at an entertainment unit to house their TV and stereo. The result is satisfying, but the journey was not without its issues.

“Our decision to buy a new 65″ TV was not as straightforward as you might think.

Our 15-year-old 42″ Panasonic Viera had served us well, but we wanted a larger screen. The area in our small living room had only one place to put it, and it was 2400mm long, between a corner and a fold-back door to our deck. In addition to the TV, the space had to accommodate a curtain for the fold-back door and two speakers on either side.

The speakers are 950mm tall and each has a 320 x 290mm footprint. These are 200-watt AE speakers and are fed from a Rotel 160-watt integrated amplifier. The system sounds awesome, which is why we put our TV through it, preferring to use our stereo instead of the sound bar that is preferred these days. Perhaps I’m showing my age, but I’ve been around stereos and sound long enough to know what I like.”

The Shed Shrink: The Drop Dead Years

Our Shed Shrink suggests there is a cunning way to avoid an earlier-than-anticipated meeting with your maker: have a laugh and have one often. Laughter lightens anger’s heavy load.

“Nothing diffuses anger and conflict faster than a shared laugh. Looking at the funny side can put problems into perspective and enable you to move on from confrontations without holding onto bitterness or resentment. It may be just a little bit of a stretch to say it may even help you to live longer.

However, a study in Norway found that people with a strong sense of humour outlived those who don’t laugh as much. The difference was particularly notable for those battling cancer. Kiwis, now we have a quirky sense of humour and over the last 20 yrs or, so our comedians have been very successful not only at home but on the big stage with the likes of the Flight of the Concords, Billy T James, Fred Dagg and Tofiga Fepulea’i – one half of the duo The laughing Samoans.”

My shed: Bill and his Harley: 60 years and counting

Bill Jackson’s Dad was an engineer and decided his son should go to university to study law, unlike the rest of the family. However, strong engineering genes shone through, and in the ‘50s, Bill accidentally became interested in restoring American motorcycles. The result: a sheddie was born.

“You know you are visiting a Wellington sheddie when, like a hobbit climbing a mountain, you ascend steep outdoor steps to access his shed, which stands as if it is propping up the rocky cliff behind it.

Technically, this is one of three shed spaces used by retired accountant Bill Jackson. And despite tricky access, or perhaps because of it, it is his favourite. Bill’s not sure what this old building used to be, but an “old boy” once told him it had been a gambling destination for the horse-racing fraternity. It certainly feels like history. It is a shed with an old soul.

The view is another advantage for a shed up high; the sun streams in, making it warm and light. Despite the steep steps, Bill and his mates managed to lug a metal lathe, drill press and other equipment as well as all his tools and general paraphernalia that accumulates in proper sheds up there.

What goes up must come down, and so it is when bikes Bill has restored need to be carried down (with the help of mates) to ground level, where they enter his other shed for final additions to be worked on.”

Back O The Shed: New tricks, old dog

Jude has built himself a new dream shed and has some big plans on what he will create in there – and it’s not what you would expect.

“Now that my shed is actually finished, I can move on to the fun bit, using it.

First of course, I have to fit it out with the usual benches and cupboards to store things. I have shelves full of fittings, fixings, solvents, oils and paints. Not to mention power tools and accessories.

The challenge is to come up with storage solutions, ideally close to where they are most likely to be used, or should I have one centralised repository? Shelves or cupboards? Freestanding or wall-mounted?

Then there is the subject of benches. I am planning on at least four and at least one mobile adjustable height workspace. The first will be the mitre saw bench. There are no end of YouTube videos on how to build one, but I haven’t seen anyone build it quite as I intend to, which is a plus and a convenient segue way into my news.”