A ministry of sound

An under-the-radar icon of New Zealand music history tells how it all happened

Larry Killip’s love of playing music dates back to 1966, when he first jammed rhythm and blues with schoolmates in a band called the Zarks.

Since then, he has played in various iterations of that band; performed solo at the Nambassa festival to a crowd of 30,000 right before the headline act, Little River Band; been featured on the compilation album 20 Studio One Hits Volume 2; released seven albums and plenty of singles of his own; made appearances on Happen Inn, Telethon, Shazam, Drop of Kulcha, and Radio with Pictures TV shows; mastered the first two albums by Indie rock darlings, The Beths; and performed a medley of his best-known advertising jingles on the TV show 7 Days. With more than 500 jingle writing credits to his name, Larry laughs when he says he is “Possibly the most famous person that you have never heard of”.

“At 73 years-young, he is still actively writing and recording original material and producing his own music videos.

Beyond sound production, he is something of a go-to bloke for fixing vintage ribbon microphones. In his spare time, he revels in op-shopping for old electronics, audio tapes, and/or eye-catching Kiwiana. He also restores analogue cameras as a hobby, and is building a portfolio of black and white portraits of some of New Zealand’s musical old guard, shot on various Rolleiflex film cameras from his twin reflex collection.

On a Sunday afternoon, though, Larry will most likely be found out in the garage, with the radio on, tinkering with his 1962 Mk2 Jaguar, which he has fully restored himself. This, he calls therapy.”

From the archives – Building an acoustic guitar – part 2

Only feel truly alive while strumming a guitar? How about taking that self-expression a step further and building your own.

This is part two of our three part series on how to build your own acoustic guitar written by Rob Bentley from the Centre for Fine Woodworking in Nelson.

In this instalment, the neck, heel, and bindings are added.

“After joining, the outside face of the soundboard needs to be smoothed, using the thickness sander and taking care to remove the minimum of material.

Draw on the outline of the guitar, using the template and aligning on the centreline. Measure from the template where the centre of the sound-hole will be and mark this on the top. A circle cutter with a small spike in the underside will allow accurate cutting of both the inside and outside diameter of the rosette channel to a depth of 1–1.5mm. The channel width is cut so that the material used for the rosette – for example, a strip of herringbone-pattern purfling – is a snug fit; otherwise glue lines will show around the edge of the rosette.”

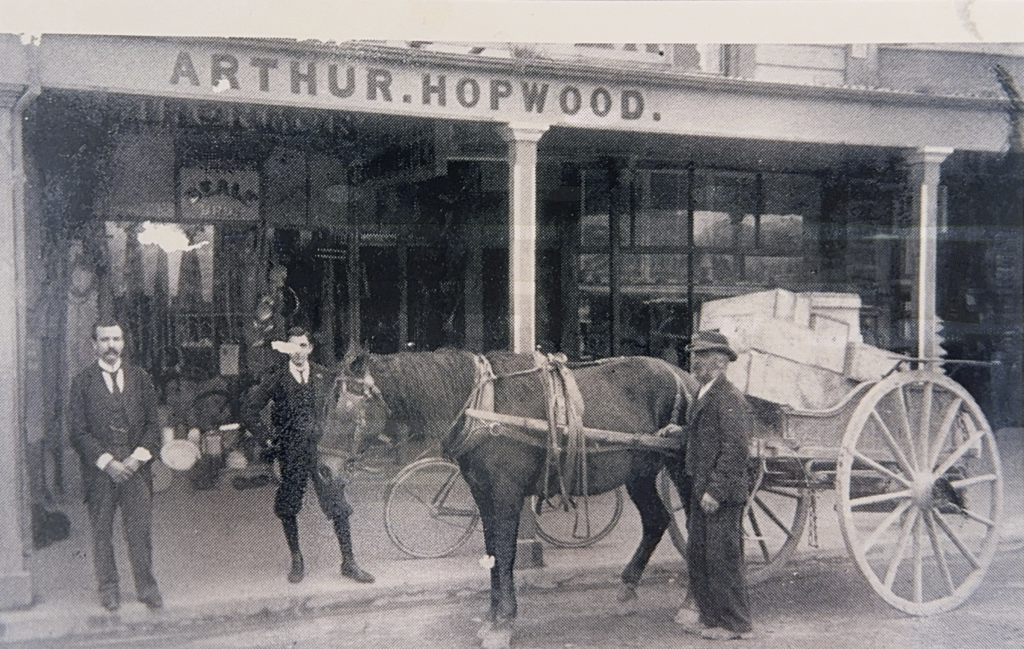

Mitre 10: 1974–2024:The First 50 Years – Part 1

The orange and black livery is a well-recognised sight throughout New Zealand, but Mitre 10 is not only a hardware store.

One of the most recognised retail outlets in NZ, Mitre 10, turns 50 this year so Nigel Young looks back on this well known and well loved, kiwi icon of DIY. There’s a lot more to them than you would have thought.

“These men are considered to be the founding fathers of Mitre 10, with an aim to establish a building and hardware supplier group. By pooling their resources, they could each offer a unified marketing model, using economies of scale to set better prices and allowing them to compete with larger hardware stores.

There is some ambiguity over the origins of the name – one being the local Mitre Tavern where subsequent meetings took place, the other being the 90-degree corner connection of two pieces of timber. The initial logo suggested the latter, although the suggestion is that it was only after Mitre 10 had been established that, “… the word mitre had a link with the hardware industry”.

Building microlight aircraft – the plane-makers – Part 1

Soaring through the skies in your own aeroplane is not just for multimillionaires

When Chris Hegan attended an event at Ardmore Aerodrome in Auckland he was fascinated by the microlight aircraft and decided he just had to learn more how to build and fly them. So when setting out to do a story about Kiwis making microlight aircraft in their sheds, he still pictured structures of wires, kite fabric, and motor mower engines, only to find that those are now 20th century relics. The game has moved on, and how.

“You don’t need a full private pilot’s licence to fly a microlight. An Advanced Microlight Certificate is easier to get but restricted – no night flying, no instrument flying, which, I discover on the way to Whitianga, means dodging even small clouds; the minute you lose visibility you are flying on instruments.

Gavin hooks me up with four blokes (he does not know of any women building their own planes), including the aerial acrobat. Three are engineers, two of whom work for Air New Zealand. The fourth, Chris Wade, left school on the Isle of Man at 14 to do his joinery apprenticeship and has built or helped to build a series of microlights. It may be useful to have engineering training but it is certainly not necessary.”

Electronics

Introduction to Arduino UNO R4 (Playing Chess) – part 3

Our programmers would welcome our readers’ help to help test their application, can you supply feedback on this application for us?

“In this third instalment, we complete the notes on the application testing we developed to verify the performances of the Arduino UNO R4, including the extra boost provided by the use of the ESP32 S3.

As already discussed in the previous articles, there is a Minima version of the Arduino UNO R4 that does not include the ESP32 S3 (a powerful ARM microcontroller); we avoided this limitation by adding an external ESP32 S3 device, facing a challenging issue on the power lines.”

Off the grid

A little bit of this; a little bit of that …

Sailing the summer away may be bliss but the day of reckoning eventually arrives for our Murray, when he needs to catch up on all his off the grid jobs and projects.

“Off-grid living consists of a never-ending list of to-dos, which in turn get prioritised by urgency – or sometimes by the looks she gives me!

Over summer, I’d been avoiding the list to concentrate on sailing, so there was a bit of a backlog. That wasn’t helped by my back ‘going out’ in response to tackling the list – a recurring problem; the wings of my L5 vertebrae never formed properly. So here I sit at the computer, dosed with anti-inflammatories, to record progress thus far.”

The Shed shrink

Heart over hustle

In a small Canterbury town, a dreamer keeps a timeless craft alive. Meet Cam Albon who has breathed new life into an old and traditional form of art: pinstriping.

“I have often admired this art, and a few years ago I had the pleasure of meeting the owner/artist of Southern Alps Pinstriping and Signs, Cam Albon. Working from his home studio as well as offering a mobile service, Cam can also be seen plying his craft at car shows up and down the country. He’s not one to blow his own trumpet; instead, he chooses to allow his work to speak for itself. He is self-taught, and the finished works sure do showcase his ability to create individual pieces with a nod to tradition but with a Southern Alps twist.”

Restoring steering wheels

Wheels within wheels

When viewing the interior of a stunning restoration, there is nothing worse than confronting a sub-standard steering wheel. It’s an often overlooked centrepiece, and a defining line between a great restoration and an average one. Meet Gary McNeill who taught himself how to restore car steering wheels when he couldn’t get quite what he wanted. It’s now his full time occupation.

“Despite your best efforts, that wheel doesn’t seem good enough; you immediately think it could have been better.

That’s exactly the dilemma Otago car enthusiast Gary McNeill faced some years ago while restoring his car. He recalls the many hours he spent solving the issue of restoring steering wheels to an acceptable standard without losing their originality.

“It was about 20 years ago, and I was restoring my 1970 Ford Mustang Boss and the wheel needed to be restored. I ended up buying a restored wheel from America, a Rimblow steering wheel to suit the car.”

Chris Gordon keeps busy – Part 3

Gordon goes electric

Chris is just as busy as ever and in this final instalment in this series of articles, our versatile entrepreneur turns his inventive mind to electrical transport which does really go the way he wanted it to.

“Chris also has decades of electrical expertise and works in the electrical industry. One of his first non-work electrical projects was a battery-powered two-wheeler. The tiny, road-registered city-car he made many years ago was originally planned to run on electricity.

Several of his recent projects have been electrical. One is a scooter, another a motorcycle, and the third a two-seater mini car, the last being custom-built in China.

The scooter is a minimalist take on the sort of device that is cluttering up city sidewalks and going by names such as ‘Lime’, ‘Jump’, and ‘Wave’. It has a 12V battery connected to a motor, which drives the front wheel by a chain. Two switches, operating together, control the motor through a relay.”

Sk8 till late

Building a miniature skatepark

A dad builds his kids the ultimate miniature skatepark for under $100. It’s always a great day when you can involve your children in a workshop project. This cunning dad did just that by 1/ making the project one that the children would be really keen on and 2/ making it small enough for small hands to be able to really contribute to creating the project.

“This project’s inspiration came from a random Trade Me find for a brand-new but slightly damaged door for the princely sum of $5.

What a great platform for a project! At the time, the kids were hooked on an Auckland-based Youtube, David Jones, with his one million followers. He makes very entertaining videos based around fingerboard skateboarding (miniature skateboards that you ride with your fingers).

Righto, back to our skateboard park. With this very light and incredibly sturdy MDF door in the car, the project could start – and oh what fun to be had with all the ideas and possibilities!”

Knife-making

A master smith in the making

The skills of young Mack, the knife-maker, already see him ready to vanquish the best.

The Jones family have a large rural shed where three generations of the Jones family create, share tasks and knowledge. This is where 14 year old Mack developed his incredible knife making skills which had a staggering outcome. In 2023, he entered the Auckland Blade Show awards and came away with Best Damasus and Best Newcomer.

“So, how did this all come about?

Well, Grumpa built a shed …

He tells us, “I started in Stratford. Grew up there on a farm, and then went to Pio Pio. There for 30 years, mainly shoeing horses. I got into engineering and built a few cow sheds, and we came down here about 15 years ago. There was nothing here so we built it all from scratch,” he says.”

Back o’ The Shed

Stihl life with a chainsaw

The contest? Man versus machine – but Jude wins the battle … eventually.

“For me, autumn means trying to secure next year’s firewood.

I’ve been clearing some fallen gums on my neighbour’s farm. It’s hard work, especially loading the rings, but it’s very satisfying and I get to enjoy these mild days working amid the dappled light.

I have recently traded my old chainsaw in on a new one. The old one was just too hard to start. I would tug away at it until it flooded and I was exhausted.”

To purchase a copy of this issue, head here to The Shed’s online shop, magstore