The shed of dreams

The cover story in our 2023 year ending issue is on the jaw dropping memorabilia collection of Terry Dalton. This is not simply a small room filled with a few bits and pieces, this is an enormous cathedral-like shed, crammed with memories. The collection is truly varied but includes a huge chunk of 1950s American Graffiti Americana including the cars and diners from that decade. Our own Kiwana has not been overlooked and there is an enormous swag of that as well. You really need to see it to appreciate it. Terry’s shed probably houses the most significant private collection of memorabilia in NZ.

“Terry likes collectibles. He has several extensive collections of different sorts of memorabilia, much of which he has bought online. He collects, for instance, oil bottles and tins, 1957 Chevrolet memorabilia, F1 stuff, musicians’ autographs, and the picks of well-known guitarists.

One corner of the shed, furnished with plush theatre seats, is devoted to the display of his treasures. He likes the collectibles not only for their own sake but also because they have a known value and are readily saleable; there is a market for them. He says that most will be sold as he gets older.“

A top table for summer

Our The Shed magazine archives have some incredible projects that are just too good to be published just once. So for our summer issue here’s another cracker project republished for readers, how to make ‘A top table for summer’.

This table will need you to use your welding and carpentry skills to complete so it’s a real skill tester for sure.

“In summer, a young or old man’s fancy, and possibly that of the family, turns to outdoor eating beside the backyard barbecue – minus the flies, of course. The question then arises: where to sit? I have seen all sorts of sizes and shapes of outdoor seating and have wanted to make a convenient outdoor table-and-seats combination for ages. I have made all-timber tables but never a steel-framed table. I chose this table because of its simplicity and the opportunity to make it all in one.”

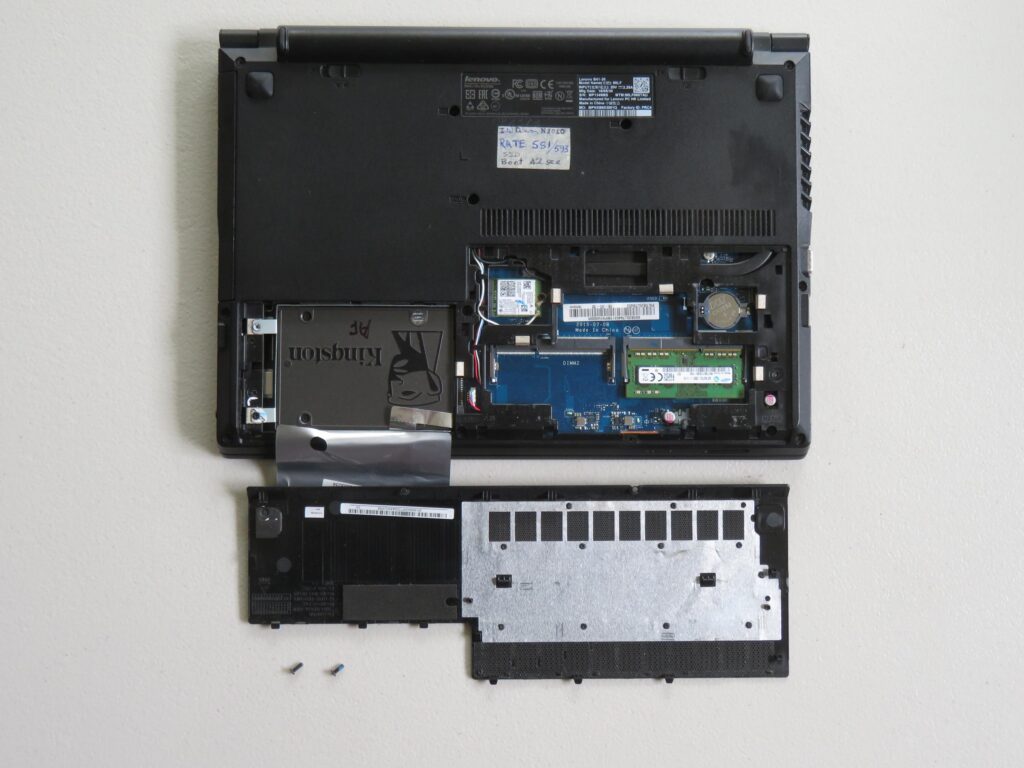

Resurrecting an old computer

How many old computers have you thrown away? If you are like the rest of us, plenty I’d say. Well these old computers can be a real asset to you in your workshop for a variety of tasks and to get them up and running and performing useful tasks for you, is not that daunting a job. Here Sandy Ferguson tells us you don’t always have to sound the death knell when given the sombre diagnosis: “Your computer has reached the end of its life”.

“However, there are those who really use their computers, and our Men’s Shed here in Rolleston has laptops being used for 2D laser etching, 3D engraving, and 3D printing.

This article is intended for those who use their computers for tasks such as finding out where to buy left-handed screwdrivers or ¹/₄-inch by 5-inch BSW screws. These laptops will probably have Windows 7, 8, 8.1, or, if more up to date, 10. They can often take up to eight minutes to boot up. The owners may have been told their system is ‘end of life’. It isn’t; it is ‘end of support’ – but ‘life’ sounds much more dramatic.“

A different kind of swansong

Sheds are not just for repairs and projects, they are also places where sheddies can let their imaginations run wild and create whatever their hearts desire. Colin Brookes is a man of many talents. If it’s “been there and done that”, he pretty much qualifies. As a child living in London during the WWII blitz he was haunted by the flying bombs aimed at his city by the German war machine. These flying bombs called ‘doodlebugs’ were powered by pulse-jet engines. Coming full circle, Colin decided to use a pulse-jet engine to power a contraption he built in his shed, a jet buggy.

“Living in Paeroa these days, Brookes started the pulse-jet project, along with building a trailer to carry the engine around, in July ’22.

“I’m down to modifications now, to make it run better; methods with injectors. It runs so hot I can’t use common sealants.”

The pulse-jet buggy is built around an Austin 7 chassis. The vehicle had been a feature in someone’s garden. A deal was done.

“I spotted it in Bulls – I got the chassis and another guy got the body. I wanted something with big wheels.”

Make a crossbow – part 3

This is the final instalment in this quest to make a crossbow.

In Nigel Young’s previous articles, he touched on the need for prioritising the design and the implications of that on factors such as weight, balance, and ease of use. In this Part 3, introducing the prod now impacts on each of these. This is no longer the archery equivalent of a rifle; the stock, sighting, and trigger are, but now weight – and, by extension, balance – has been introduced. The final result is a terrific looking crossbow that is remarkably accurate to boot.

“In my first article in this series, I quoted Jeremy Clarkson: “How hard can it be?” Was I really that naive? I’ve been working on this project throughout this past year, with three magazine deadlines to meet along the way. This last deadline was given a two-week extension and I was still working on the article right up until the last minute.

One crossbow tiller and stock became two, one prod became five – of which the three laminated wooden ones broke, while the remaining two were steel made from a car spring and a length of T-section fibreglass that I cut down at the cost of a bandsaw blade that was about to be replaced anyway. Apparently fibreglass is very hard on a saw blade, so be prepared to discard it once you’re finished.”

Off the grid

Our resident off the gridder, Murray Grimwood undertakes dozens of projects in his off the grid shed. This month Murray rejoices in some of the smaller jobs needing to be undertaken and the real satisfaction that can come from those smaller jobs and taking a moment to appreciate some bloody well built vintage tools.

“Sometimes I need to promise myself a reward at the end of long-haul drudgery – an “If you get through this, you can do that” kind of thing.

That was how I dealt with the daunting task of rabbit proofing our biggest garden, our two chook runs, and the berry patch – “Once you get round them, Muggins, you can indulge yourself.”

Then there are the excuses that crop up while you’re drudging – tasks that just have to take precedence. For example, I’d presented my favourite girl with a sports car after mildly refurbishing it a few months back, but her brother broke the steering column. It seemed important to repair it, given that she was coming up to 16 – months, that is.”

The Shed shrink

Rex Short – a man with zeal

Hopefully you have a mate like Rex. One of those guys who can do anything and fix anything and do anything for ya. Well Mark Seek wants to introduce you to a real good barstard in Taranaki.

“The bloke I want to introduce to you is somewhat of a local identity in the small settlement that sits under the white-capped mountain of Taranaki. The majestic peak, reminiscent of Mount Fuji, is the backdrop when Rex Short prepares for his day before dawn. Rex even manages to stir the cranky old rooster in the chook pen.

Now, if Rex isn’t test-driving his scratch-built Lotus 7 ‘project’ through the twisty, foggy lanes of Inglewood – that would be before the local cop tucks into his brekky and coffee – he can be found walking his Border collie, Kuri. Rex tells me he feels the morning ritual is an important time to focus. He explains that the land around him, and the connection with it, inspires him each day; the words he chooses are ‘contentment’ and ‘gratitude’.”

Project: Table saw sled – a must-have for your workshop

The best home workshops are the best for a few good reasons and one being, having the right tools for the job. Andrew Broxholme reckons a Table Saw will really add to your workshop arsenal of great tools and in this issue 112, he shows us how to make our own.

“The table saw is a must-have for anyone wanting to make anything serious in the home workshop. I was taught to use one by my father, who even made his own saw-bench for cutting firewood.

Step forward 20-plus years and I’m in England; I had just bought my own home and figured I could try making some of what I needed, such as trellis and small fence panels. I started with a cheap saw-bench – as is recommended if you haven’t used one before and want to practise with smaller projects without a major outlay of capital.

When I returned to New Zealand in 2014, I upgraded to a larger and more accurate Makita saw-bench. It served me well for the next few years. As I now had more experience and was making better-quality items, the cost was justified because it’s easier to cut more accurately on a higher quality saw-bench. You can make things accurately on a cheap saw-bench, it is just more frustrating and takes longer.”

Max’s shed – part 2

Max’s dad explains the importance of the six Ps

Max and his dad have made significant progress since the last issue of The Shed with walls now up and a roof securely fastened on. The hope is to get it all completed by Christmas. It’s coming along nicely.

“While the weather has been quite awful since our last update, Dad and I have managed to make some progress on the shed. Back in August, we finished all the frames. Dad talks about the six Ps: ‘Perfect Preparation Prevents Piss-Poor Performance’.

Well, he must have applied those to the frames we built because, with help from Dad’s mate Aaron, we carried the frames out of the garage and had them all securely in place within three hours. That said, Dad found that our socket wrench was not up to the task of tightening the anchor bolts into the concrete pad. Aaron came to the rescue by nipping home and fetching a real one. Maybe Dad needs to treat himself to a real socket set.”

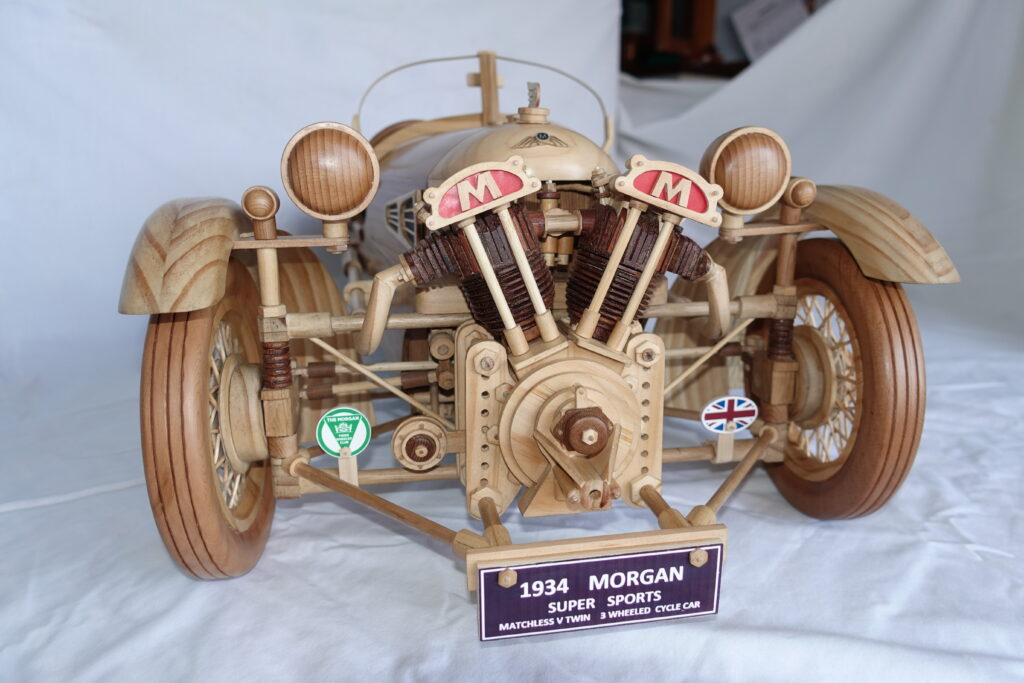

Model making

The Quintessential Craftsman

It all started for Wayne Nicholls 23 years ago when his wife casually asked him if he could make a tissue box for her. He had a few bits of wood lying around and thought he could make something out of those. After that, it was a toilet roll holder. Then he really went to town on what may be the fanciest potato storage box ever made. By now the pattern was set: a dedication to extreme perfection of detail and the idea that he could make anything out of wood.

“Moving on to models, Wayne first made a few toys, by which time he had fallen into the routine of going out most evenings to his small garage in northern Geelong, about 70km from Melbourne, and making stuff. He didn’t use sophisticated and expensive machinery, though. That’s not Wayne’s style.

“Too easy” is a phrase that pops up again and again in this classic Aussie yarn-spinner’s vocabulary. He made his first productions with a Black and Decker drill and a bunch of hand tools.

“I don’t really want to make life easy for myself. If it’s hard, that makes it worth it,” he says. It also puts him ahead of the competition.

“Who else would go to the trouble?” he asks with a laugh.

Wayne’s first excursion to showing his work was with balance toys that he entered in the 2002 and 2003 Geelong shows. Although they pale in comparison with his later work, they are fascinating and clever things – a cowboy and a Native American riding galloping horses that hang on the edge of a table and closely emulate the natural movements. He was rewarded with second and third placings at the shows.”

Engineering

Slade Engineering changes hands

A Christchurch engineering company’s owner has retired, and a new, younger owner has taken over. The two men, superficially different, have a number of things in common.

“Both Shaun McGrath and Louis Slade met their wives on the west coast: Louis in a noisy bar in Los Angeles; Shaun in New Zealand.

Both wives come from North America: Kristin McGrath from Ottawa and Nancy Slade from Chicago. Both have a daughter and a son. Both like the outdoors; for Shaun, it’s mountain biking and for Louis, it’s hunting, fishing, and boating.

Shaun would like Slade Engineering to be increasingly automated so that the effects of inflation can be, at least partially, controlled. He’s already installed a robot welder and would like to bring in other CNC machinery, expanding the business.”

Robot your life – the grass is always greener

In a world full of gadgets and high-tech machines, a young Auckland dad finds harmony in going all electric with his garden and lawn tools.

After a dangerous mishap with a ride-on petrol lawnmower, Mark Gibson decided it was time to go all electric with his lawn mowing and well, one electric thing led to another electric thing, and another…

“Swapping my petrol ride-on for Bobbie has seen added benefits and a financial win. No more fuel costs, or petrol cans in the car. Routine maintenance is a breeze; I simply swap Bobbie’s blades every few months. The blades resemble mini razors and do an excellent job considering their size. MowBot sends a box of new blades to my doorstep every 12 months.

We have now also replaced all our petrol-driven gardening tools with 18–36-volt versions. My partner loves using the chainsaw! There is a lot more confidence in the overall use, as there is no idling motor, it’s far quieter, and it is obviously less fumy and greener for our environment.

Petrol-powered leaf blowers and lawn-mowers create a lot of noise pollution in our neighbourhoods.”

Miniature railway

A man of many talents, Ian Jones has created a fairytale attraction for the young at heart in Whanganui.

Ian is a coach-builder by trade. On leaving school in Wellington, he did a coach-building apprenticeship with New Zealand Railways at the Woburn workshops.

Ian says that when coach-building, you learn woodwork, metalwork, welding, painting, upholstery, so you get good at everything. It was a very good skill base.

“Ian has designed and made the track, doubled-skinned tunnels, train sheds, and varied landscape features over the past seven years. The kick-start to this ongoing project was the chance buy of a locomotive on Trade Me.

“I’ve had model trains all my life – little trains — but I’d never experienced a ride on a train like this until the day I went to pick up that loco. So I thought, “I’m going to build a railway.”

Back o’ The Shed

The end is nigh. A new shed for Christmas … maybe

The Shed magazine founder Jude Woodside has been building a new shed on his new rural property and he’s getting excited. He can see the end.. Hopefully.

“I am in the final stages of finishing my shed. The enclosure is almost done, and I am awaiting the roofers to do their thing. I would do it myself but at my age the prospect of working at height is less appealing. I just don’t bounce as well as I might have 10 years or so ago.

It’s been an ‘interesting’ journey, a bit like the Chinese curse “May you live in interesting times”. I started this project nearly two years ago, expecting to be in the shed last year. I selected the site in a paddock near my house and spent some time building a road for access to the site. That involved a thorough education in civil engineering and the practical knowledge of fencing I received building gates to access the paddock.”

The Auckland Blade show

The annual show is over for another year and we have a full report on this year’s bigger and better than ever event.

Kiwi-built motorbike show

Could it be NZ’s isolation at the bottom of the world that inspires Kiwis to tackle near-impossible tasks?

To purchase a copy of this issue, a back issue or to subscribe to a print or digital version of the magazine, head to our online shop.