Make your own tambour lounger

By Stuart Lees

Photographs: Stuart Lees

When I made my first tambour door a couple of years ago, what immediately struck me was not the functionality of the door itself (although it is not without its aesthetics or merits), but that it would potentially make a really comfortable deck chair.

This project is the realisation of that idea. Using a long tamboured top as the basis for a piece of furniture, I decided to make: a tambour sun lounge.

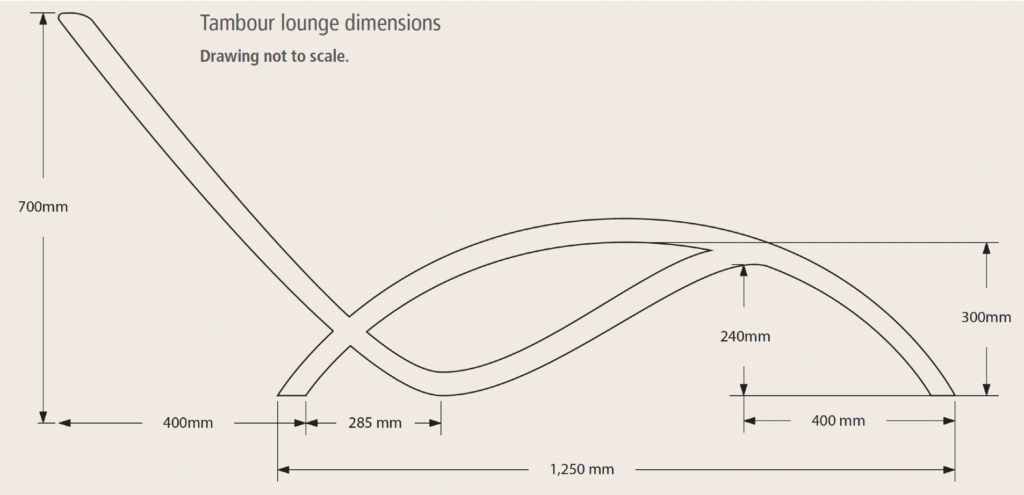

I expect most people would be familiar with the classic roll-top writing desks, popular in the 19th century and a progression from the solid-topped Bureau du Roi, or “Secrétaire à cylindre de Louis XV” from 1769. The tambour form particularly suits itself to the ogee curves and it is that aesthetic that inspired the form of this sun lounge.

Base

There are a few methods for bending timber to form the frame:

- kerfing would not be strong enough—being primarily a decorative process;

- steam bending would be a great method, except that I don’t have access to the equipment, and more importantly, nor do most readers;

- laminating strips around a form would be quite a viable method. It would produce a structure that was strong enough and stable. It would require a bucket of glue, a king’s ransom in clamps, and turn about 75 percent of the timber you use to sawdust so, although I considered it briefly, I went in another direction.

The method I decided to go with for the base involved cutting out shorter lengths of timber and joining them together. This has a few benefits.

Wastage: (or a lack thereof) Each section is cut from the same timber supply that I use for the tambour top, being lengths of 90 x 45 mm hardwood. While it doesn’t sound like you can make much of a curve with that, with a bit of careful planning it is very feasible.

Strength: While the joint between sections is a bit of a weaker point, I overcome this by allowing a significant amount of overlap at each scarf joint. The strength benefit comes from grain direction. Each section has the grain running along the member rather than across it, making a shear failure highly unlikely. As the direction changes significantly along the length, cutting the entire length of the frame from one board would result in areas that were purely cross-grain, with a high likelihood of failure.

Ease of manufacture: It would certainly be easier to cut the frame from one piece,except for the potential for it to break in use. While creating multiple scarf joints is not my favourite activity, it is still a lot simpler and easier than the other viable option of laminating pieces around a form.

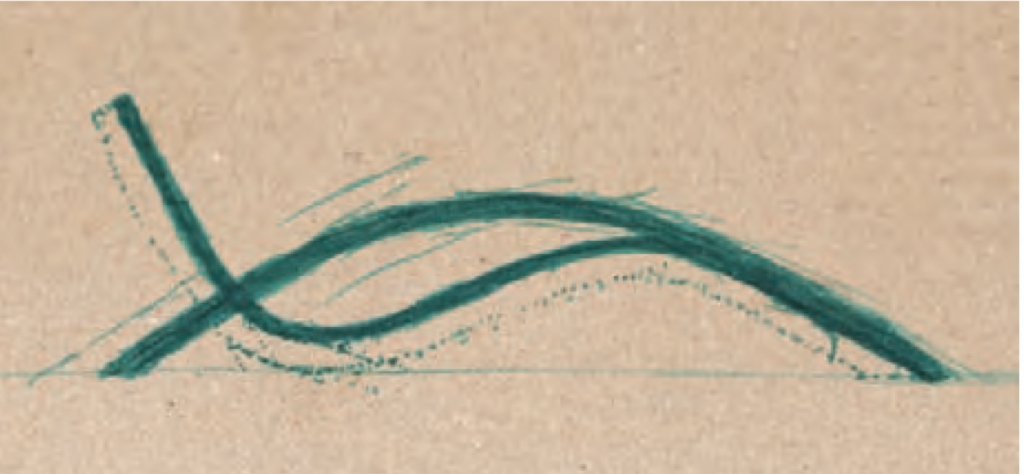

Mock-up

To start, I made a mock-up of the frame by taking thin offcuts of the 90 x 45 mm timber (which were around 90 x 5 mm). These were laid out, overlapped, juggled, drawn on, then roughly joined to create the shape I was looking for. It is important to ensure the areas that would be subjected to the most load had the grain running in the correct direction.

The location that takes the highest amount of load is at the base of the back. This has both the largest change in direction and has to support almost 50 percent of the person’s weight when they lean on the back of the lounge.

Once the outline looked reasonable, I cut the frame close to the final dimensions on the bandsaw. I then disassembled it and copied each piece onto a sheet of 6 mm MDF to create the templates. I temporarily joined them together. A 23-gauge micro pinner is a particularly useful workshop tool for this. I then sanded it with both disk and spindle sanders so the curves all flowed from one template to the next.

These were then separated and attached to the final boards, which I had dressed on the jointer and thicknesser to produce lengths that were straight, with parallel sides, and of a consistent thickness. I used the 23-gauge micro pinner for this, although double-sided carpet tape would be a functional alternative.

I cut each piece as close to the template as possible with the bandsaw, then used the disk sander and spindle sander to get each piece as accurate as possible.

If you don’t have a spindle sander, a cheap drum sander that fits a drill press would work just as well, and there is a sanding disk that fits a tablesaw if you don’t have a disk sander in your workshop. While a bandsaw is an invaluable workshop tool, you could use a jigsaw for this job (especially one that is inverted and mounted in a table).

Joints

I cut the scarf joint in each piece, marking them out first and then using a lumber crayon to clearly depict the piece to cut away. I used a combination of a coping saw and bandsaw to clear away the unwanted portions. Next I glued the joints with Titebond Polyurethane Liquid Glue. This is both waterproof and an excellent gap filler—my scarf joints are not the best examples of woodworking.

Once the glue had dried, I sanded each piece again, then glued the seat supports to the arm rests using Titebond III Ultimate Glue, which is also waterproof.

Tambour seat

Many wooden tambour doors are made by cutting individual slats, then joining them to a cloth backing to create the door, or threading them together with wire. Neither of these solutions have any appeal to me. With the availability of routers in particular, a fully wooden tambour can be manufactured with interlocking pieces without any need to glue them to a backing (or to string them together).

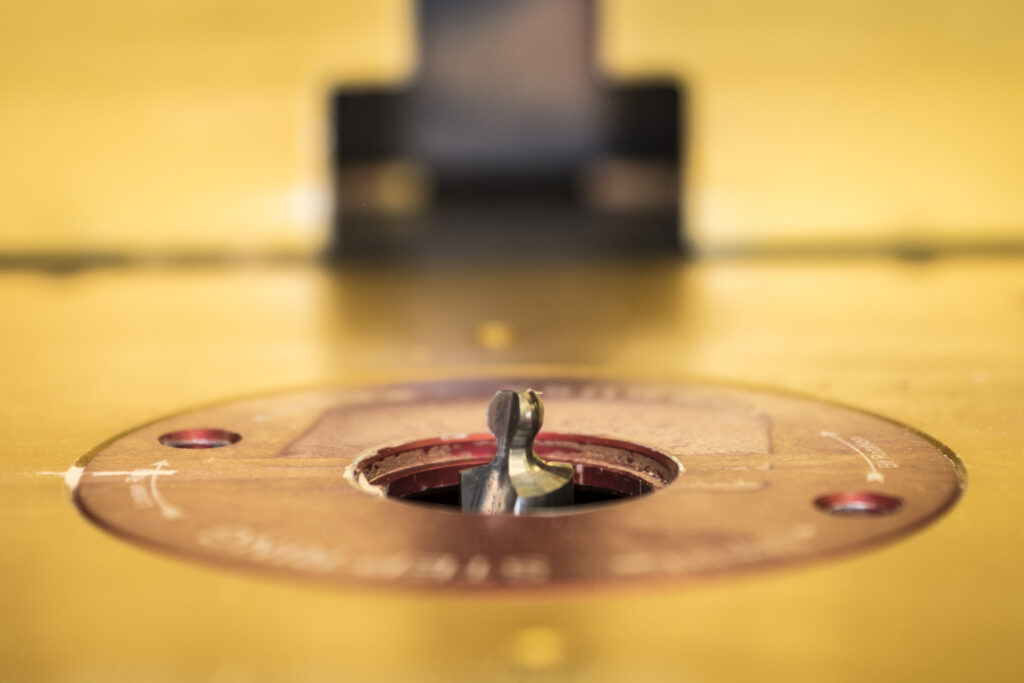

The specific router bit set I used for this project was sourced from toolstoday.com, called the Lonnie Bird Tambour Router Bits Set by Amana Tool. It consists of one router bit that produces the side profiles and a second one that cuts the rounded slot that each piece slots into. There is a third bit, a basic round-over bit, which isn’t needed for this project.

Precision

I accurately sized the timber on the jointer and thicknesser to 51 x 14 mm. This is a little wider than normal as I wanted to ensure that the tongue on each slat was as strong as possible, so I compromised on the overall flexibility of the resulting tambour. As this is not a sliding door and you are not trying to create tight curves, it doesn’t cause any problems.

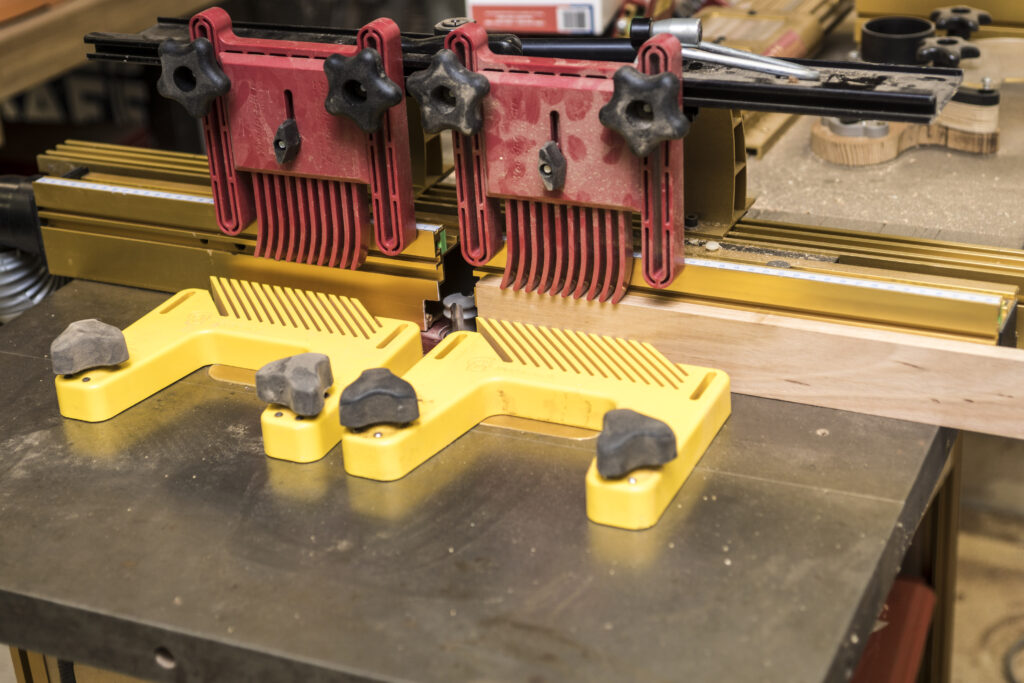

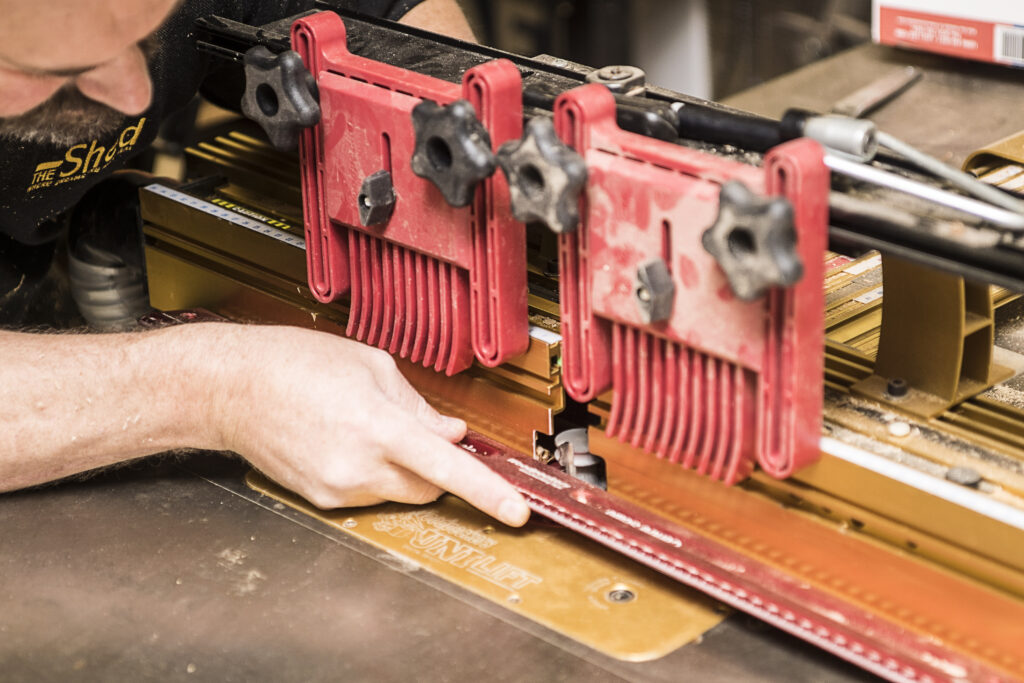

With the router bit mounted in the router table, I used a straight edge to ensure it is collinear with the fence. I then used featherboards to hold down the timber on the table and against the fence. This minimises the change of variations in pressure which cause an uneven cut and keeps your fingers well away from the cutting surface. It also makes the operation faster, as board after board can be fed quickly through the machine at the optimum feed rate for the cutter and without pauses from one board to the next, especially near the ends of each cut.

The first router bit produces a fancy “I” profile. This is in fact two tambour slats laid out head to head. They are separated into individual slats in a later step. Before cutting the slot in the base of each slat, it is best to remove as much material as possible on the tablesaw. The ball router bit is solid carbide for strength, but the less work it has to do, the better.

The tablesaw blade height is set very low—just enough to remove the material from the centre of the slot. I then ran each length through the ball bit on the router table. Again the featherboards make the process as easy as possible.

Slats

To finish the ends, I left one slat without the bottom slot and the second with the bottom slot, but I cut the tongue off the top. This provided a slat for each end of the tambour that looked finished.

After I formed the slats, I separated them on the tablesaw and the job is done. I’d like to think it is a lot easier than other methods for producing a tambour door and having a solid timber mechanical joint is a lot more appealing than one that relies on glue and fabric, or wire.

Lastly, I docked the slats to the required length on the dropsaw. I decided 600 mm was a reasonable width for the lounge and, as my original timber was 1800mm long, it meant I could get three slats from each length, minimising wastage.

Even so, the process of producing the tambour slats generated about 100 litres of sawdust.

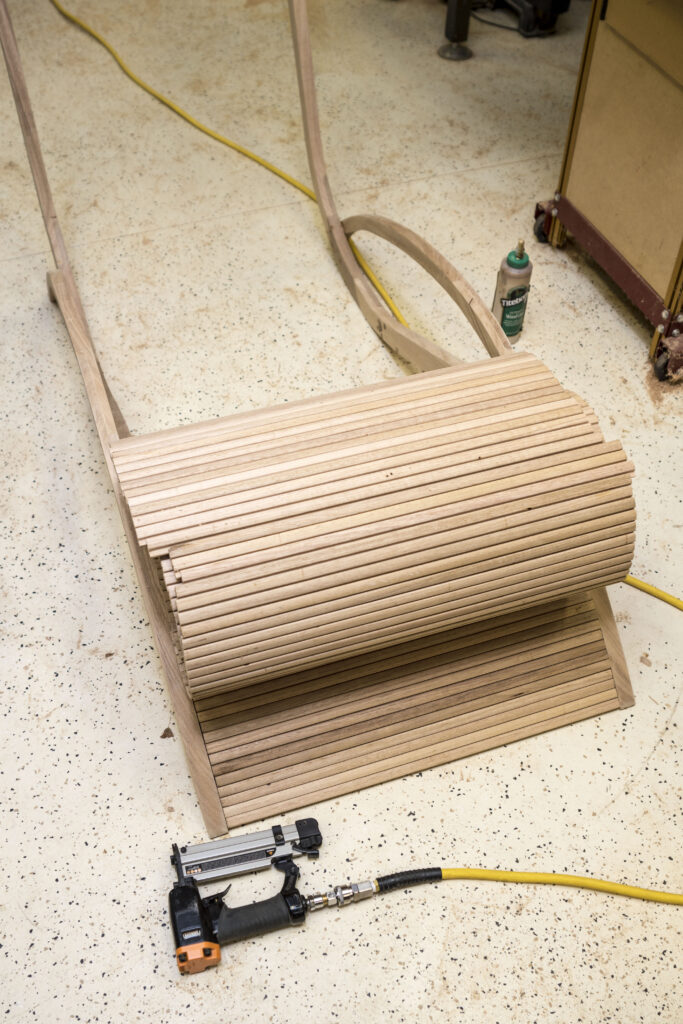

I found storing the tambour in a roll until it was ready to be attached was safest and also the easiest way to attach it. Starting at the foot end, I rolled the first few slats out onto the rail that I had coated with the glue. The 23-gauge micro pinner again proved that it is worth its weight in gold as I used it to pin the end in position almost invisibly and with little or no risk of splitting.

I coated further up the rails with more of the glue and rolled out the tambour further. I repeated process until the whole lounge frame was covered.

Strength

While I had some reservations early on about whether or not the tambour would be strong enough to support my weight without additional cross bracing, it proved not to be the case. I am able to stand on it with all my weight on one foot without the slats breaking. I weigh more than 100 kg and that is probably pretty close to the limit that it can support, but that is a relatively small load-bearing area and normally the entire length of the lounge will be supporting the body.

I was surprised how relatively light the lounge is. It is definitely heavier than the wicker lounges that have become popular in recent years, but it is still light enough for one person to lift and move around.

After a final light sand, I brushed the entire unit with Danish oil to protect the timber and give it a finished look. A simple finish like Danish oil makes it easy to maintain, as further coats can be brushed on as required. I coated all the surfaces, even those that generally won’t be seen, so it is fully protected. After all, the lounge will occasionally be lifted up and moved, especially to get the best combination of sun and shadow.

This was a fun project, especially with the unique concept of the tambour top, which is very comfortable. There were some left-over slats, so a small drinks table and/or a portable lumbar support will quite likely be a future project.

Now that this design has proven the concept, the next time I try a similar project I am planning to incorporate the ability of the tambour top to be reconfigured to different shapes, allowing the chair to be set to different positions, or for people of different sizes.

The lounge was made in a couple of weekends, so it was a bit more involved than some of my previous projects, but it is still quite achievable with a standard range of tools.