A bike enthusiast relishes the challenges of a rebuild

By Sarah Beresford

Photographs: Adam Croy

Simon Dew has a thing for Italian and English bikes – think Ducatis, BSAs and Royal Enfields. Over the years he has spent hours in his shed labouring over rebuilds and his passion for restoring bikes has been undimmed by the sometimes tortuous process.

“It’s all a bit nonsensical really,” he admits. “It would be much easier to go out and buy a bike that’s up and running and hit the road but for me it’s not about the bike itself but the process.”

Simon likens rebuilding bikes to herding cats. “Getting compliance so a bike can get back on the road is often long and arduous – and then you’ve got to keep it going. There are thousands of processes you have to consider and often the bikes will have been apart for so long that there’s no contiguous process for you to consider. Things like ignition systems, valve timing, and carburettors can have dramatic effects. It’s not a linear process from the outside to the centre. Often problems that appear bizarre and insurmountable can be caused by something quite simple.”

But it’s the challenge of the build that Simon loves and has him coming back for more. Over the years he has worked on a Ducati 860, a 1951 RE Bullet, a 1981 Moto Guzzi 500 Monza and a 1970 BSA B44 Shooting Star. He currently has two roadworthy bikes that he rebuilt and rides regularly – a Royal Enfield “Bitsa” that he built from a wrecked early ’90s standard Bullet 350 from Madras and a number of spares he had left over from a 1951 350 Redditch Bullet that he had restored; and a BSA B44 Shooting Star that he bought sight unseen online – it had been changing hands as a project for more than 20 years before he got hold of it.

“Often problems that appear bizarre and insurmountable can be caused by something quite simple”

Minimal costs

Simon says the key to doing the work on the bikes is that he can keep costs to a minimum by doing many jobs himself: “Almost nothing is outsourced which keeps costs down considerably. If I need jobs like some aluminium welding for a cylinder head or reboring I get that sort of thing done but I can do a lot myself in my shed.”

Although largely “self-taught” he gives a nod to the years he spent as a kid restoring cars with his father. “We did a vintage car restoration course at Manukau Tech which was really fabulous. I learnt to weld among other things and we worked together restoring an old Riley. My older brother Martin was into bikes in a big way and he had a big influence on me.”

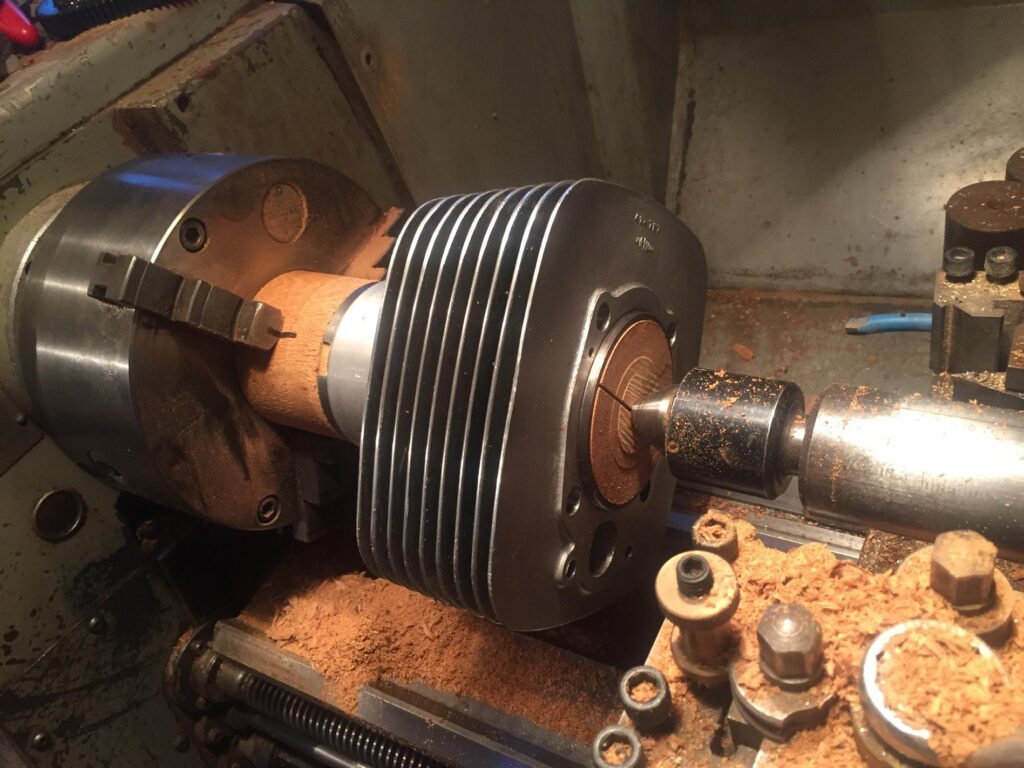

He says one of the most useful pieces of equipment he has in his workshop shed at the bottom of the garden of his central Auckland house is his Myford lathe.

“I got it off an old boy in Epsom and it really takes what you can do in restoration to a whole new level. I’ve made things like nuts, bolts, and screws from steel stock. It really pumps you up a few levels in capability.

“I’ve used it as a jig on it for working on crank shafts. The possibilities of what you can do on it are amazing considering all it does is basically turn things in a circle. The great thing is that it’s totally consuming when you work on it as you have to give it your full attention – you can’t think of anything else or you risk pranging the lathe.

“The other thing is that it works on Imperial measurements so you get very good at converting thousands of an inch to millimetres and back. It’s a great brain trainer,” he says laughing.

“It’s been an ongoing saga. The one thing I think I can rely on with it inevitably fails”

Problem solving

Simon says the BSA B44SS has been one bike that has presented him with plenty of opportunities to test his powers of problem solving. “It had been assembled just for the pictures on TradeMe but it was never going to run in that state. It’s blown up four times and it’s been an almost weekly disassembly trying to address the issues. One of the problems was the manual had confused the B25 with the B44 so that proved a bit of an issue.

“It’s been an ongoing saga. The one thing I think I can rely on with it inevitably fails.”

Simon is comfortable doing a range of jobs, from using his oxy acetylene gas welder to fix a crack in the BSA’s gas tank, to doing the finishing paint job. “I’m happy to strip everything off and use my spray gun compressor to do a paint job. Maybe that’s where years of buying tired old cars and spraying them has paid off,” he says laughing.

He’s rebuilt instrument panels and resealed them on the lathe, made clutch pullers and other service tools on the lathe and set up crank shafts on the same indispensable piece of equipment.

Often what seems like a serious problem can end up being a quick fix: “The Enfield used to make an ominous clack-clack sound when it was idling which had me really puzzled but it turned out that it was only that the oil pump spindle slipping due to my running slightly too heavy a grade of oil.

Simon says it’s the ongoing problem solving that he finds so satisfying in a build, although there’s nothing that can beat the thrill of hearing a motor turn over for the first time: “Starting a bike you’ve been working on is like music to your ears. Although you have to hope there’s not doing to be ongoing problems and you’ll have to hear that tune over and over again. Still there’s nothing quite like going on a ride on a summer’s day on a bike you’ve rebuilt yourself.”

“I’ve pretty much been bitten by the BSA bug”

Road trip

Simon recently got to have a taste of the proof of the pudding in terms of the troublesome rebuild of the BSA when he went on a return road trip to Wellington with a mate.

“I bought the bike in 2016 and the rebuild has taken me about a year. The major work was done in three months or so and then it was sorting out the rats and mice, which seemed to take forever. So doing a 1200 km trip in two days was a great test.

“We had a couple of glitches on the way down – the condenser wire broke at one stage and the carb came loose – but on the way back it was faultless.

“It had plenty of pep too. It managed to keep up with my mate who was riding his Velocette Venom, which is a pretty posh bike,” he says laughing.

But Simon isn’t content to stop with the latest rebuild: “I’m looking for a BSA A10 Road Rocket or a Golden Flash to work on next. I’ve pretty much been bitten by the BSA bug. Having done two rebuilds I’m pretty much in my comfort zone working on them. It’s good to be in zone and familiar with the various marks. The Golden Flash bikes have very successful motors and the great thing is that they are in a very accessible price bracket.

“They are perfect for home repair jobs and make for a pretty low-cost hobby. The BSAs were very popular in America so you can source lots of parts on Ebay and even locally. It’ll be great to get started on a new bike project.”

See more about Simon’s bike rebuilds:

https://classicbikerestoration.wordpress.com/2017/06/25/first-blog-post/

http://b50.org/phpBB2/viewtopic.php?f=14&t=7050

The B4SS rebuild

Photographs: Simon Dew