A look at the most common types of nuts is a logical companion article to the post on fasteners, also on this, The Shed, website

By Bob Hulme

For our purposes, a nut is an internally threaded part which is rotated or screwed onto an externally threaded part such as a screw, bolt or stud. If you can pick it up in your hand and put it onto an externally threaded item and tighten it, it is a nut. There will be some exceptions to this which will become apparent.

Hexagon full nuts

The common, hexagon-shaped nuts we are all familiar with are available in steel (with different tensile strengths), brass, aluminium, nylon, stainless steel, and titanium. Finishes for steel nuts include galvanizing, zinc plating, yellow chromate and of course black which is bare steel without a protective coating. They are called full nuts because their height is about the same as the diameter of the thread. (An M8 nut would therefore be approx 8 mm high.) This gives the maximum theoretical strength.

Thin hexagon nuts (lock nuts)

These nuts are around ½ to 2/3rds the height of the hexagon full nuts. Their main use is as a locknut tightened against another to prevent the first nut from coming loose, effectively locking it in position on an externally threaded part. A good example of this is the depth stop on a drill press. Locknuts are ideal where nuts are not tightened to a surface but need to stay in a certain position, such as with a space adjustment, or where a particular end float is required.

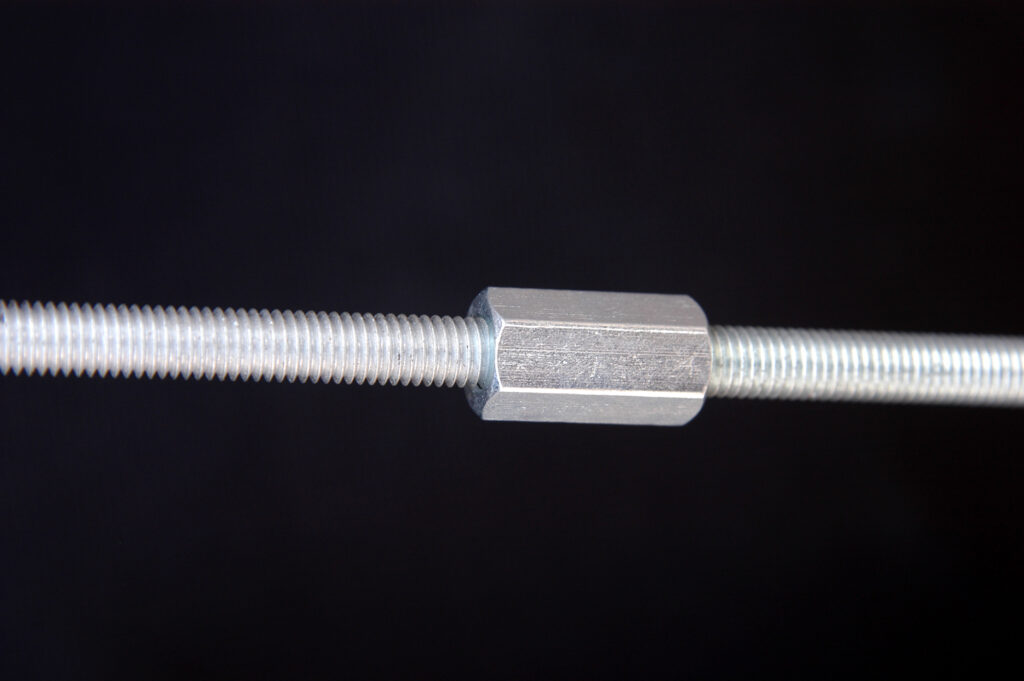

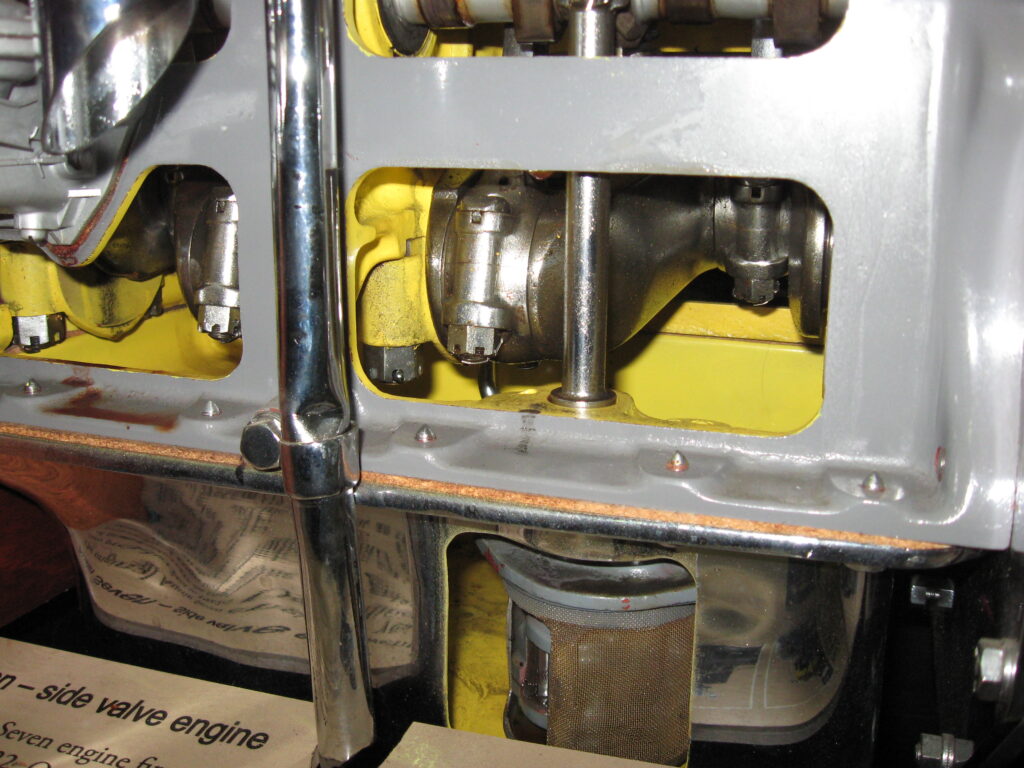

Deep nuts, long nuts

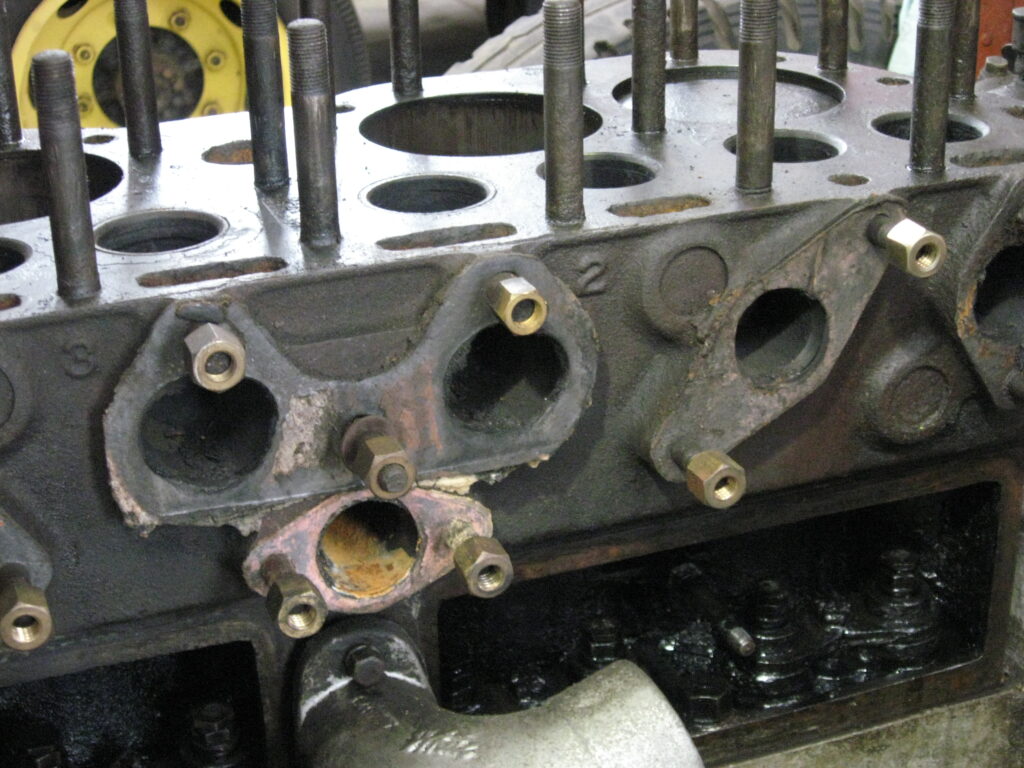

Deep nuts are generally double-height hexagon nuts and are mostly used where the nut is made from a softer material than the bolt or screw, such as brass. You may remember when brass deep nuts were common on car engine manifolds. Long nuts (or rod couplers) have even more height than deep nuts and are typically used to extend a threaded component. Imagine that you need a tie-rod two metres long and the threaded rod you want is only in one-metre lengths. By using a long nut you can join two pieces together to get the length you need. Using thin nuts to lock the long nut in place can also be useful.

Flanged hexagon nuts

These are common in the automotive industry and substitute for the essential washer-full hexagon nut combination. When you tighten a flanged hexagon nut, the spanner or socket does not contact the surface as you tighten the nut. If there was no flange to work against, the spanner could leave unsightly marks in the paintwork. Flanged hexagon nuts are usually available only in steel with either a zinc-plated or yellow chromate finish. Most flanged nuts have a serrated face to the flange that helps to prevent loosening due to vibration.

Dome nuts

Dome nuts have a blind threaded hole in them, meaning the hole does not go right through. At the blank end, the nut is dome-shaped to give a better appearance where the nut is visible as the finished item. Brass dome nuts can look great against natural timber. Also available are dome nuts in stainless steel and nickel-plated brass with a “chrome” look.

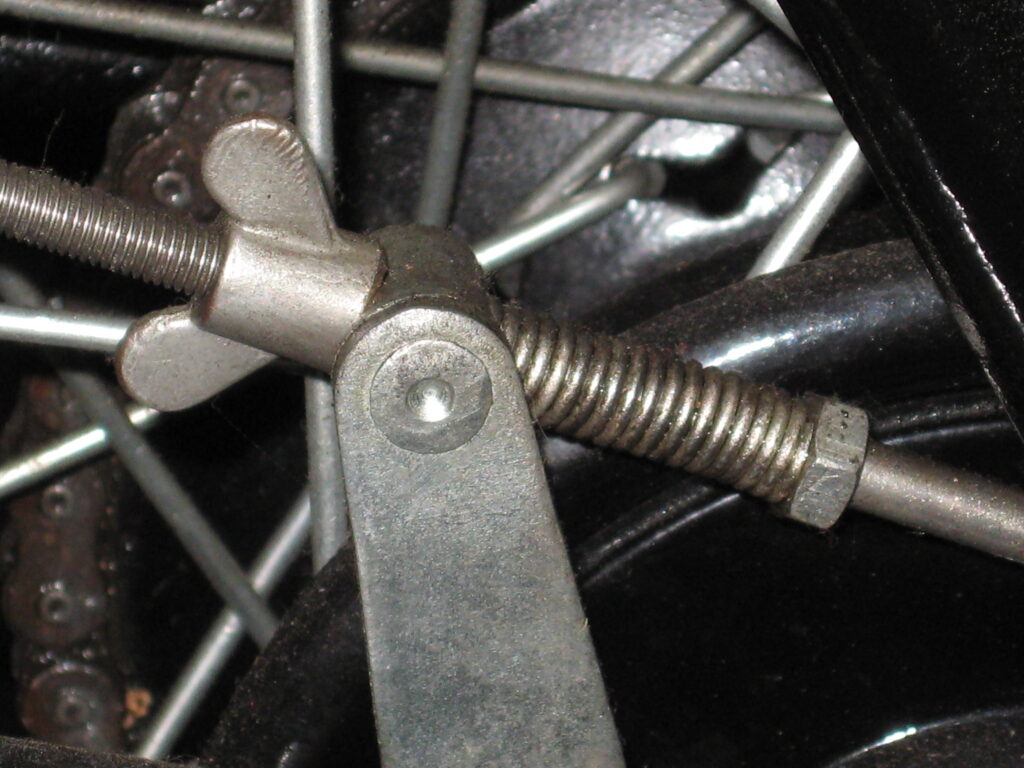

Wingnuts

Setting aside schoolboy references to guys with stuck-out ears like Prince Charles who were cruelly nicknamed “wing nut, ” these useful nuts allow enough leverage to be tightened without you having to reach for a spanner every time. They are used where a nut has to be undone and done up again often. Today, they are being superseded by classier-looking plastic-moulded handles and knobs. When we go to so much trouble to bolt a piece of equipment together it’s annoying when vibration, thermal fluctuation, or maybe just gremlins cause the nuts to loosen. Fortunately, there are several options to help us overcome this problem.

Nylon-insert nuts

Nylon-insert nuts are commonly referred to as Nyloc nuts after the registered trade name of Forest Fasteners. This style of nut has international patents. Nyloc nuts have a ring of nylon crimped into the top of the nut. The nut spins onto the bolt or screw easily at first, but as the bolt thread forces its way through the nylon, there is enough resistance to require a spanner on the nut. This tightness prevents the nut from shaking loose. As a teenager, and even later in life, I raced go-karts. Every nut had to be a nyloc nut and all threads fine-pitched ones or else the vibration from a high-revving, two-stroke motor, would have them undone in no time. The purists would say that you should only use nyloc nuts once and discard them. I tended to use them around four times before replacing them. It is possible to feel when they have lost their tightness and it is time to toss them into the recycling bin. Nyloc nuts are available as full hexagon nuts but some stockists also have flanged versions.

All-metal tight nuts

These nuts are tight because they are slightly distorted in some way or have a metal insert that works similar to the nylon insert in a nyloc nut. Their advantage is that they remain effective at higher temperatures than a nyloc nut can tolerate. Cone lock-nuts are one example. On top of a hexagon nut, they have a raised, press-stamped conical section that is slightly distorted and this makes the nut tight on a bolt.

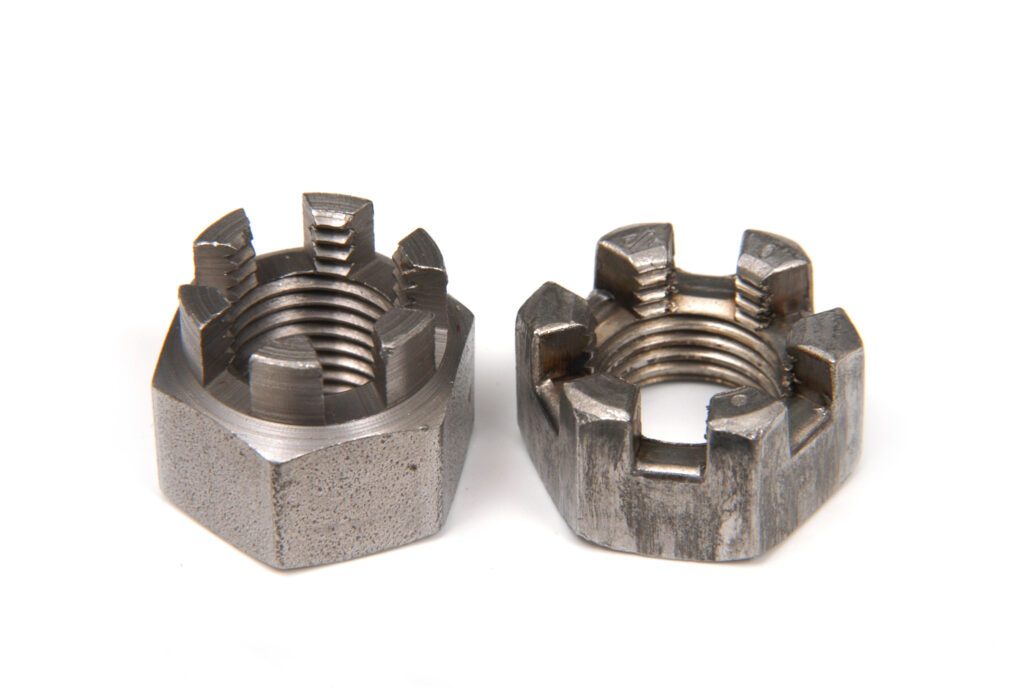

Slotted and castellated nuts

A good way to prevent loosening is to use a split pin or cotter pin with a slotted nut (a hexagon full nut with slots cut across the top). We can lock the nut in position with the split pin across the slots and through a hole drilled across the thread of a bolt or screw. A castellated nut has a raised portion on top of it for the slots (“castellated” from the castle turret look). This positive method to stop a nut from unwinding is not used as widely as it once was because of cost.

Washers

A variety of washers can help to keep nuts tight. Nord-lock washers are a comparative newcomer that is amazingly effective. They are used as a pair and have toothed surfaces that interact with each other. The old spring washers are losing favour. I think this is because of the prevalence of aluminium-cast components because spring washers gouge into soft materials like aluminium. Wavy washers do a similar job to spring washers but are kind to surfaces. Schnoor washers have a conical shape like a Belville cupped-spring washer but have serrations on both sides. Their popularity is slowly increasing.

Chemical locking

Another way to prevent nuts loosening is to use an anaerobic adhesive product. The most iconic brand is Loctite, but there are many other brands such as Permabond, Wurth, Loxeal, and Omni. Anaerobic adhesives set off once contact with air is removed, hence the name. That is why bottles are never full when you buy them—they need an air gap to stop them from going off. Super glue is also an anaerobic adhesive. From the different strengths available in thread lockers, it is wise to select the one only as strong as you need as sometime in the future you may need to undo that nut. Check the specifications before you use these products as they do have temperature limitations.

Rivnuts

Also called nutserts. These are an ideal way of establishing a threaded hole in thin metal and especially in hollow sections such as square tubing. They are fitted just like a blind rivet. Up to M8 are easy enough to fit but above that size, specialist equipment is needed.

Tee Nuts

Two quite different types of nuts are referred to as tee nuts or T nuts. I have always known tee nuts to be those used in machine-tool tee slots for clamping the work and that seems logical because of their T-shape. The other type of tee nut is really a headed round nut with spikes pointing down from the head. They are used in timber where you drill a hole the same size as the shank of the nut, drop the nut in, and hammer on the head so the spikes sink into the timber. The tee nut will stay put and not turn. They can be used in chair legs to mount casters or in table legs to fit screw-in adjusters.

Tools

Where simple hand tools were once convenient to tighten hexagon nuts, a lot of modern effort has gone into the high-tech development of the geometry of spanners and sockets. Rounded corners on hexagon nuts should be a thing of the past. The shape in many ring spanners now is often referred to as flank drive, as the shape is modified so that the contact patch on the nut is just away from the corners. This means that a stronger part of the nut is taking the stress and there is less chance of slippage. Multifit spanners for many nut sizes (one spanner can be used for metric and imperial nuts) have been around for a while, but the latest ones are a further development.

Adjustable spanners

Adjustable spanners do the most damage to nuts and are responsible for nearly all the rounded nuts. Put a set of ring and open-end combination spanners on your wish lists for birthdays and Christmas. Even if you get more than one they can be left in different locations such as the car, the shed, and even the kitchen. If you’re given an adjustable spanner, ask the giver if they have kept the receipt so you can exchange the gift. Be kind to nuts all year round.

Book

For a good reference, the Fastener Black Book will have more information than you need, but that’s what a reference book should be like. You can order your copy through Machinery Warehouse https://www.machineryhouse.co.nz/l344.

It has information on imperial as well as metric fasteners, tensile strengths, and surface finishes.