What you need to know for your welding set

The gas bottle story

With a gas welding set or your own MIG or TIG welder at home in your workshop or shed, you need to understand gas cylinders and how you need to look after them.

Pressure

Gas cylinders are pressure vessels, rated for high or low pressure depending on the gas in them. All cylinders are tested and date-stamped at regular intervals; these tests are mostly done every 10 years but every five years for CO2 cylinders . Tests can only be done by a certified tester. All cylinders must be filled by certified fillers. It is illegal and very dangerous for any of these certified fillers to fill cylinders that are out of the valid test period or that have no test stamp. This same restriction also applies to your LPG cylinder (the old barbecue bottle).

Colours

Cylinders are colour-coded for safety. The most commonly used gases and the colour of their cylinders:

1. Black for oxygen (O2);

2. Maroon for acetylene (C2H2);

3. Blue for argon (Ar);

4. Grey for carbon dioxide (CO2);

5 Silver or cream for LPG;

6. Brown for helium (He);

7. Blue with a grey top for Supashield (for MIG welding

Sizes

Cylinder sizes vary in capacity from 0.5 m3 to 10.5 m3. There are checks in place to prevent the wrong gas getting into the wrong cylinder. Gas companies reserve the right to refuse to fill a cylinder if they consider it to be unsafe, and have a very strict policy not to fill any cylinder that is out of test or not coloured correctly. There is a case study where one man painted a fixed-colour cylinder a different colour so that he could change the gas he was getting; obviously, a dangerous and unsafe practice.

Argon regulator and flow meter

Different sizes for argon bottles

Owning or renting

You can either own or rent a cylinder. When you buy a cylinder, whether from a dealer or on Trade Me, you own the cylinder outright and are responsible for keeping it in test and good repair. Owning a cylinder may be best if you are planning on not using your gas set much.

A good gas cylinder that is looked after and tested at the correct intervals can last for more than 50 years. However some of the older (mainly acetylene) cylinders can’t be filled as they would fail at testing.

The only downside of owning a cylinder is that the major gas companies are naturally more interested in the bigger user of gas and not the home handyman. They may try to sign you up for a hire cylinder instead.

If you are lucky enough to have one of the smaller gas companies in your area and it has oxygen and argon, they should fill your cylinder. An acetylene gas cylinder will take a week or two to fill. For acetylene, most areas will have a service centre that will send your cylinder away to be filled.

Renting

When you rent a cylinder, the gas company will look after all the testing and maintenance. You have to open an account and they will charge your account the monthly rental. Some of the larger gas companies may also have other charges: an account fee, a per-cylinder delivery charge, a minimum charge, a fee if you don’t turn over or fill the cylinder more than three times a year and various other charges.

Large gas companies may discourage the small user by high prices where the small gas company may charge only the rental with no account fees or any other fees. It can be the case that any rental cylinder you hire will only be filled by the company you rent it from.

Pure argon must be used for TIG welding

Black bottles for oxygen

Exchange

Until recent years, there was a system of getting cylinders that was called an exchange system. You paid a fee upfront to lease a cylinder long-term and the gas company running the system would exchange the empty cylinder for a full cylinder without you needing to pay rental or open an account. This system has now stopped and the company has a policy of recalling those cylinders (SEE Panel, Exchange cylinders).

Co2 outlet. Note male thread

Oxygen outlet. Note female thread

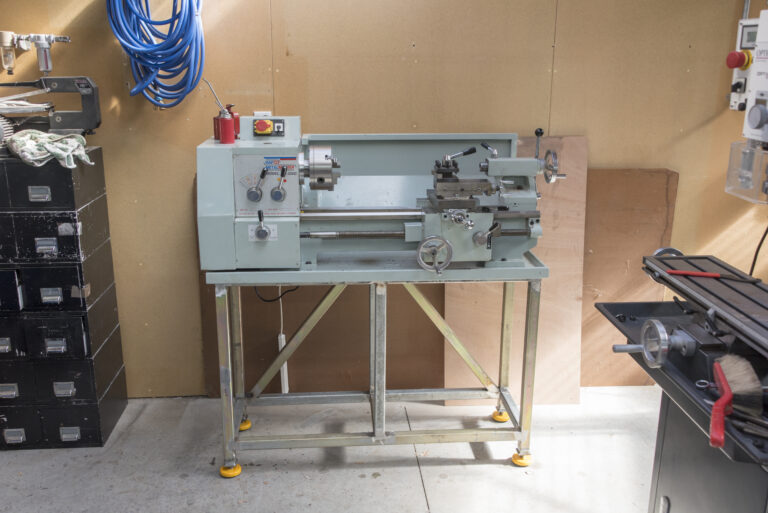

Basic gas set

The basic gas set consists normally of an oxygen cylinder and an acetylene cylinder, but you can also have an oxygen cylinder and an LPG cylinder.

Oxygen (o2)

Oxygen forms 20.95 percent of the atmosphere around us and is taken from the atmosphere by means of an air separation plant. Air is compressed and chilled until it becomes a liquid. Then, as the chilled liquid heats up, gases vaporise or boil at different temperatures. Oxygen, for example, is drawn off when it boils at -183º C. The oxygen is then chilled again, liquefied and pumped into storage in this liquid form. When it comes time to fill the cylinders, the liquid is vaporised, compressed and pumped into cylinders at high pressure up to 200 bar or 3000 psi.

There is an inherent danger in the high pressure. Oxygen is not flammable on its own but it can promote burning. The fire will burn hotter with added oxygen and in some cases you can have spontaneous combustion when oxygen is mixed with oils. So any equipment that uses oxygen must be oil-free and should only be used in a well-vented area. CAUTION: Oxygen and compressed air are not the same. It is dangerous to confuse them. A case study demonstrates this vividly. A mechanic was working under a truck in the yard and became dusty. He came into the workshop and dusted himself down with the oxy cutting torch. His overalls had oil on them. The oil mixed with the oxygen and spontaneously combusted. The mechanic received burns to 60 percent of his body and was seriously disfigured. This is just one example of the misuse of oxygen as if it was compressed air.

MIG welding. A gas shield mix of argon and CO2 is best for welding steel

Acetylene (C2H2)

The basic and original method by which acetylene is made is from calcium carbide mixed in water. This gives off acetylene. Other modern methods include the passing of methane through an electric arc, causing partial combustion of the gas, or the steam cracking of hydrocarbons and the subsequent treatment to separate out products such as acetylene from the cold cracked gas stream.

Acetylene has a distinctive smell some say it is like garlic but it is fairly pungent. It takes less than five percent in the atmosphere for the atmosphere to become explosive.

TIP: If you go in to your shed /workshop and smell acetylene, don’t switch on the light and go and look for the leak. The switch may generate a spark which would ignite the acetylene mixture. Just open the window and vent the whole room. Then look for the leak on the bottle with a mixture of soapy water.

A problem with acetylene is that above 15 psi the gas becomes unstable and may explode or spontaneously combust. The only safe way to transport it is to dissolve it in acetone which will absorb up to twice its own weight of acetylene.

Within the cylinder, the acetone is dissolved in a porous mass, now commonly agamassan, developed and patented by the Swedish physics Nobel Prize winner Gustaf Dalen, although also used is diatomaceous earth also known as diatomite or kieselgu— a porous, pumice-like powder from fossilised algae.

The pressure within the cylinder is 250 psi and, as there is little or no gas space, it makes it safe. This is the only safe way of transporting this gas. This is also why these cylinders should always be used and stored in the upright position.

Correct storage

CO2 regulator and flow meter

Acetylene filling

It is time-consuming to fill these cylinders as acetone absorbs acetylene only at a slow rate. It is not safe to speed up the process which can take up to six hours for big cylinders.

Acetylene cannot be decanted cylinder- to-cylinder without very specialist equipment. The cylinder has thermal pressure relief valves which will vent the gas if the cylinder heats up.

The cylinder test every ten years involves removing and checking the valve, thermal pressure relief valve and the porous mass. If this is damaged or has shrunk, the cylinder is condemned. If the cylinder has too many dents it is condemned.

Inert gases

Inert gases used for MIG and TIG welding are normally argon, CO2 or a mixture. Pure argon

must be used for TIG welding and aluminium MIG welding.

Argon is acquired from the atmosphere (there is less than one percent) by a process similar to

the one which captures oxygen, using an air separator. Because there is less argon in the atmosphere,

it takes longer to capture and thus the gas is a lot more expensive.

Argon comes in blue-coloured cylinder and can be up 200 bar in pressure (high pressure) This

gas is inert which means it will stay the same and not change when heated, making it the

perfect gas for shielding a weld. Argon is non-toxic but in confined spaces it will deplete the

oxygen and asphyxiation is a risk.

CO2 (carbon dioxide) is mainly obtained as a by-product from the petrochemical industry and

comes in liquid form in the cylinders. CO2 liquefies at a really low pressure so the pressure (160

bar) in a CO2 cylinder is lower than in any of the other inert gas cylinders. It is a very cold gas

and there is a risk of frost-burn. CO2 can only be used for MIG welding but in most instances

you will find a mixture of argon and CO2 is best for welding steel. All gas companies have their

own brands and mixtures.

Brown for helium bottle

Storage

The way you store compressed gases must comply with the Hazardous Substances and New Organisms (HSNO) regulations under the HSNO Act 1996, controlled by the Environment Risk Management Authority (ERMA). In general, Material Data Safety Sheets for compressed gases recommend that cylinders should be stored away from ignition sources and kept in a cool, dry, well-ventilated area out of direct sunlight and away from heat. Cylinders should be stored in an upright position on a firm level floor, preferably concrete, secured by a solid fixed chain and separate from empties. In addition, all oxygen cylinders should be kept oil-free and stored away from any sources of oil.

Helium bottles stored

Rocket

Safety with all gas cylinders, all highpressure vessels, is very important. The simple but stark warning in the Material Safety Data Sheets for most gases—Hazard Risk: Ruptured cylinders may rocket.

Every cylinder should be fixed securely to the equipment it is being used on. A gas set (oxy/acetylene) must have a trolley with a chain to secure the cylinders or they must be fixed to a permanent stand. With a MIG welder, the cylinder is normally fixed to the welding machine.

If gas cylinders are not used for a long time, they should be removed from the equipment they are installed on and stored outside.

Equipment

All equipment used with the cylinders should be in good order and to New Zealand/Australian Standards. It is dangerous to use old and substandard equipment. Some old, local equipment was designed to work at lower pressures. Because modern pressures in cylinders have increased, equipment more than ten years old should be replaced regardless of condition. But you should use only equipment designed for modern pressure levels. Do you want to take the risk with a cheap set that may not be able to stand high pressure?

There are some gas sets being sold in this country that may not be made to any standard at all. The brass in the acetylene regulator may not be the correct alloy. Brass with too much copper in it may cause copper acetylates to form; these very unstable crystals may explode.

Be very careful of equipment from overseas as different countries operate with different pressures. Cylinders from some countries may not be rated for New Zealand. For instance cylinders from Afrox (a South African oxygen company) have deferent valves and are not compatible with anything sold in New Zealand. The same caution goes for gas equipment. If you are in doubt, ask your local Supagas dealer or service centre.

Cylinder valves

There is a range of standard valves on the cylinders in New Zealand. The different types of threads are all safety features of the cylinders. The thread on the inside of a tube is a female thread; the thread on the outside of a tube is a male thread.

Blue with grey stripe for supashield

Right-hand female thread

-Oxygen(02)

-Helium(He)

-Argon (Ar)

-Argon mixes

-Some Nitrogen

Note: There are two types of thread for nitrogen in circulation. The first is a female thread which is the same as for oxygen and argon. These have been standard for a number of years. The second is a new Australian standard male valve introduced a few years ago. With some of our gas equipment Australian-made, there are attempts to make this standard in New Zealand. But the female thread is still the New Zealand standard.

Left-hand female thread

-Acetylene (C2H2)

-LPG

CAUTION: Acetylene valves are not the same as LPG valves. Even though they each have left-hand female threads, they will not fit each other’s cylenders. Use only LPG valves with LPG cylinders and acetylene valves with acetylene cylinders.

Brazing copper tube with oxygen / LPG mix

Black oxygen and silver LPG tank. Nte orange hose for LPG

Right-hand male thread

– Carbon dioxide (CO2)

– Nitrogen (N)

The valve for pure argon has a gas retention

valve. This valve holds a positive

pressure within the cylinder so

that the atmosphere (air) can’t enter

the cylinder and contaminate the next

gas put in the cylinders. These valves

are the same with all the gas companies

in New Zealand and Australia.

LPG regulator

Tips

– Always use flashback arrestors on gas sets.

– Always make sure you use ersonal protection equipment

(PPE) i.e. goggles, gloves and the like. Material Data Safety

Sheets note that persons moving cylinders should be provided

with safety footwear, safety glasses and leather or

PVC gloves. Full cover overalls are recommended. Clothing

should be of 100 percent cotton or fire-resistant to prevent

static electricity which could cause an ignition and also

melt onto the skin. All personal protective equipment

must be free from oil and grease. With some gases,

approved breathing apparatus is needed.

– Never let children play with your gas equipment.

– If you have owner cylinders, get them filled at an approved gas supplier

– If you are storing or using your gas set in a garage which is alongside or under your house, check with your insurance company as this may invalidate any insurance you think you have.

Final Note

For safety if you have any doubt about a cylinder or a piece of equipment, please consult your experts at your local gas company. There are too many dangers if you cut corners and take risks with cylinders.