By Roy Purvis

A garden fountain windscreen-washer pump is driven from a solar panel.

Solar-powered water feature. Note the half-submerged windscreen washer pump.

I suppose all waterfalls are solar- powered – the sunshine evaporates the water which turns into clouds, becoming rain which pours down into waterfalls. So the publisher’s challenge to make a small solar- powered pump for Greg’s sculpture seemed not too difficult.

For the pump, I chose a windscreen washer pump from a Nissan Pulsar, because it’s recycled material, and it will pump enough water when powered by a 6V battery. Windscreen washers squirt water through a narrow tube, but trickle it gently through a wider diameter. The electric draw in this project is less than one amp, so I asked Independent Power for a 12Volt 1 amp photovoltaic (PV ) panel. The one I used is rated 20 watts peak, 1.3 amp maximum. However, I knew that when the PV panel + and – are connected to the pump, nothing happens. There is no kick available to start the motor. So I needed to build an interface to make it work.

Tube from pump through boat.

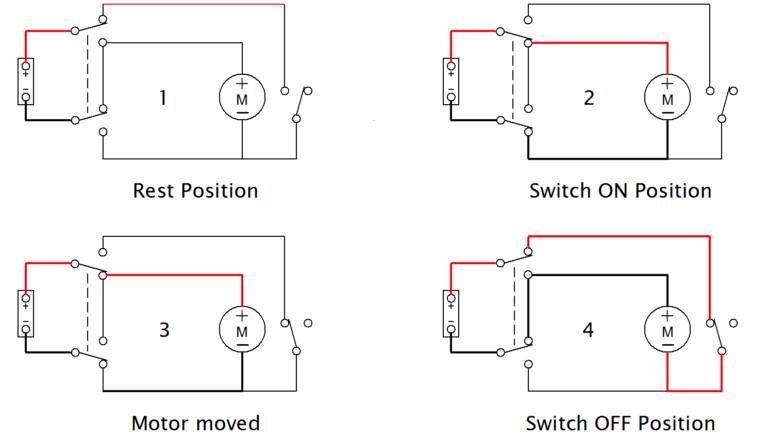

First, the PV panel is connected to a big capacitor to store up energy and a “royswitch” is used to turn the pump off and on. This is an electric switch for a big DC lamp that is remotely turned off and on by a small wire and mechanical switch. It uses a mosfet as found in amplifiers and inverters and power supplies these days. This one is recycled from a computer monitor power supply. These are very good because when they are turned on by applying a few volts to the gate, there is virtually no energy loss as heat.

RAPID SWITCHING

Next I used an LM311 comparator to turn on the switch when the capacitor is charged up to 13 Volts. When the voltage drops, the comparator turns the switch off and waits for the sun to shine enough to charge the capacitor up to 13 volts again. This is achieved by dividing the voltage across the capacitor by a 3k3 and 2k2 resistor, effectively 2 / (2+3) comparing the fixed 5.2 Volt zener diode.

Roy Purvis tackles the electronics

The big advantage of this “solar pump driver” is that it will rapidly switch on and off to get the pump motor started. All these short pulses of high amps is just what is needed to start a DC motor. Thanks to the fast diode across the motor, the average electric current in the motor is more than the PV panel is making. When the FET switches off, the electrons want to keep running through the inductance of the motor and they can do this by travelling via the fast diode and back to the motor.

Electronics in a bottle

Most parts come from computer scrap – the LM311 and zener diodes I got from Jaycar, along with a coreva board to assemble it on. I put the completed circuit board in a small honey jar with the four wires passing thru the lid, then waterproofed the lid with a bit of sealant.

A couple of words of warning: sparks can damage electronics, so be careful making the connection. Turn the PV panel away from the sun to turn it off. The pump must always have water, as it will fail if it runs dry. It’s best if it is half- submerged as the water cools the motor. This device could be scaled up, using more solar panel area for a bigger pump.