Casting in metal from printed moulds

By Vik Olliver

Shot glass printed

So can you print in metal?” This is one of the oft-asked questions from people who have just discovered 3D printers. The glib answer is “Yes, but the machine costs half a million bucks.”

But that’s not the whole story. If you consider a 3D printer as a machine for printing the first stage of what can then be cast as tools, jigs, and moulds, then making metal objects with even a low-end 3D printer becomes possible. Here we’re going to use 3D printing to do a modern twist on “lost wax” casting.

It’s a trick that’s more than 5000 years old: make something in wax, bury it in clay or plaster leaving a hole in the shell. Bake the heck out of it to remove the wax and then pour molten metal down the hole. If everything stays together, you get a metal replica of your wax object.

Mixing plaster with iced water to slow the reaction

Painting the mould with plaster

Adding fibreglass as a medium for filling the hole

First print

Our modern version is very similar. You first print objects in pure, clear PLA rather than sculpt or print them in wax—though wax is actually used by jewellers and the like who have special 3D printers. You can use a tinted, clear PLA too, as that uses dye rather than pigment. A pigment is a powdered colour that would transform into undesirable muck in your mould when baked. The dyes, on the other hand, are used in far smaller quantities and usually get destroyed by the heat.

We’ve used DiamondAge’s New Zealand-made Diamond, Ruby and Sapphire filaments, with great success, casting objects ranging from pewter rings to high-tensile steel components weighing several kilos.

So let’s start with “Yorick,” a 3D-printed PLA shot glass that can be downloaded from http://www.thingiverse.com/thing:38282 as a shareable design and scaled to suit your thirst. The model needs to be 3D-printed with enough perimeter layers to keep the plaster out, particularly on the upper surfaces.

The finer your print resolution, the more perimeters you need. Internally, use as little fill structure as you can get away with. Yorick got a good clean up (called “chasing” by the artisans), with unwanted cavities and defects getting plugged with beeswax. You can produce a very smooth finish with beeswax and a hairdryer if needed.

Before getting plastered, Yorick was first dunked in water. This dampens the surface and lessens the chance of trapped air bubbles. These will show as unsightly blisters in the final casting so, as you brush on your first coat of thinly mixed plaster, try not to froth things up.

Placing a thermocouple into the mould to monitor the temperature inside

Plaster

Because we’re only casting pewter here, we can use plaster of Paris mixed in a rather ad hoc manner. For other metals, you’ll need silica, alumina, and other higher-temperature mixes which is another story. If you use chilled water, the plaster takes longer to “go off.” Don’t mix more plaster than you can handle and discard the excess if it goes lumpy.

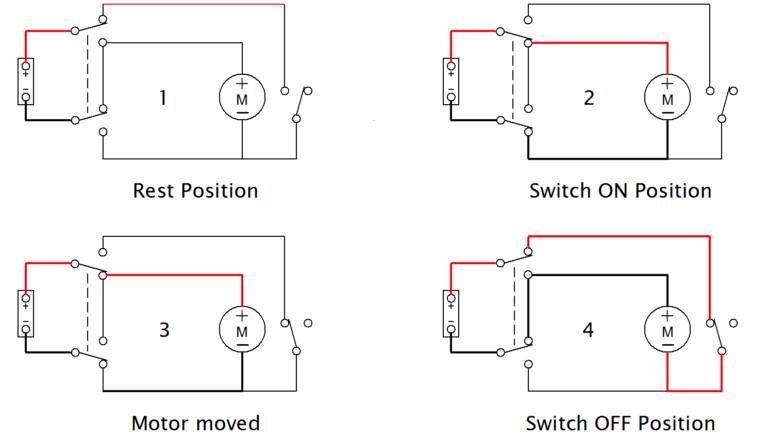

Leave a gap in the plaster coat at what will be the highest point in the mould. We’ll attach sacrificial bits there to form tunnels—for air to come out and for metal to go in—tunnels called, in the casting world, sprues. On this particular model, we can have them pretty close together. With more complex models you may have to have several sprues to let the air out where it would otherwise form pockets in the casting.

To add strength to areas that will become big, unsupported lumps of plaster-like Yorick’s booze cavity, pack them with a squishy mess of Pink Batts and plaster for reinforcement and anchoring. We sometimes implant a thermocouple probe in large castings so we know what’s going on inside.

You may or may not be able to recover the thermocouple…

Adding a candle as a sprue for pouring the metal

Layering

Once the base coat is on, you can thicken the mix and start layering the plaster on much more generously. It hardens quickly, so it’s practical to prop up the object in a small dish and pour plaster all over. But before you completely bury it, add parts to form the sprues. These can be specially printed parts, or you can just use pieces of PLA printer filament and candle.

Weld them on with a small, hot flame. It’s a very good idea to embed the part in a tin or aluminium can full of plaster. Should your mould crack, this holds the metal in and you can generally salvage something. Otherwise, you may just end up with a bench full of smoking, molten pewter. Ensure you do not completely bury your pour hole and air holes. The pour hole shown was a bit small and we widened it with a knife before pouring (trying hard not to let the chippings enter the mould).

There needs to be a reservoir of metal available as the mould cools down because as the liquid metal cools, it shrinks by a few per cent. With a low melting-point metal like pewter you simply make sure the pouring funnel has plenty of room in it—you can always reuse the excess metal, and it sucks when you have 99 per cent of an object cast.

With higher-melting-point metals, you may need to have a big funnel to provide a decent head of filling pressure or hide several reservoirs deep inside the mould. The mould itself generally dries quite quickly; leaving a mould the size of Yorick overnight was adequate. But the big secret of using lost-PLA moulds successfully is that before baking out the inverted mould at 300º + C as you would with wax, you have to ensure that the whole mould is gently heated through to 100ºC. This allows the PLA to become soft enough to flow out of the way as bubbly things happen inside. Otherwise, pressure builds and the mould will split.

The thermocouple comes in very handy at this point, giving a reliable indicator of how hot the middle is. A tinfoil tray without leaks is also handy, as it prevents the oven from filling with decomposing plastic.

Fortunately, PLA fumes are not particularly toxic, but using the domestic oven might cause strife so we have a little toaster oven and some ventilation in the shed.

Completed mould

Leave it to cure overnight then into the oven

Stabilising the mould at 100 °C

Temperature up to melt plastic from mould

Ready to be filled

Pewter

Some hours later, depending on mould size, the plaster will look well-baked and stuff stops dribbling out of the holes. The pewter you want to use to fill it is Britannia Standard Pewter— accept no substitutes. This is lead- and cadmium-free (i.e. it’s mostly tin) and is poured at a temperature of about 350ºC, though it melts around 290ºC – 300ºC. Small 200 – 400 ml crucibles from foundry suppliers are great, but a tin can will do it at a pinch.

An aluminium can will absolutely NOT do.

Lacking a proper furnace in the shed, we pointed a MAPP-gas torch into a well-balanced crucible until the pewter was very fluid. The dross was then scraped to the back of the crucible with a bit of welding wire, tongs were gracefully deployed and the beautiful silver stream was guided perfectly into the pour-hole (yeah, right) until metal came out of the air hole.

Because the metal is poured while the mould is still hot and remains molten for some time, the mould can be tapped with a stick to release trapped air bubbles and even quickly topped up if necessary. Then you have to wait.

When all is cooled, destroy the can by any means necessary and free the cast. Yorick’s mould experienced some minor cracking, resulting in leaf-like protrusions of pewter that were easily chiselled off. Soaking the plaster makes it easier to brush off and a water blaster can make quick work of things (as well as flinging your masterpiece across the yard). We stuck with a wire brush and a bucket.

After we sawed off and filed down Yorick’s sprues, he was polished with a fine wire wheel and christened with a well-earned tot of 100-proof rum.

Going beyond the bean can, this technique has real-world uses too. In fact, 3D printers are emerging as a relatively cheap means of producing patterns for moulding large cast components. They have the advantage of being cheap to produce and easy to modify and reprint.

They are fast becoming a necessary tool in engineering workshops especially as the qualities of PLA are becoming apparent. PLA will melt easily and can burn off with little or no residue. ABS is not so accommodating—it requires much higher temperatures and will leave some residue, making it unsuitable for making moulds.

Melting the pewter

The mould being poured

Cracking the mould

Cleaning up the casting

PLA print of Yorick

The metal casting