Few can fault an efficient hand tool, says DIY inventor

By Tim Brewster

PHOTOGRAPHS: ANNA ALLAN/ALPINE IMAGES, JUDE WOODSIDE

It splits wood and rock, it severs roots, it leverages…it slams. The Slammer may be a literally ground-breaking tool to work with, but the manually operated device is a rare creature in the thriving high-tech landscape of new DIY tools.

Developed by TJ Irvin, a globe-trotting American who settled by Lake Hawea more than a decade ago and handcrafted by one of the oldest engineering firms in the country, Templeton & Sons, the Slammer is an unusual piece of kit any manual worker needing a bit of extra grunt should consider trying.

The 9 kg, two-piece Slammer developed by Irvin uses the impact of a solid, high-tensile steel rod rammed down a length of pipe by the operator. This provides the momentum to ram the attached blade into—and through—the sort of material most people hire a jackhammer to deal with. Other attachments turn it into a fence-hole rammer and a compacter for foundation work. As TJ describes it, the slammer/rammer multipurpose tool is a combination of a crowbar, axe, spade, mattock and sledgehammer all in one. Made in New Zealand.

Resourceful

“Every tool invented has started with a problem,” says TJ Irvin. He’s a voluble, self-confessed tinkerer and outdoorsman who started developing this tool more than 15 years ago.

Apart from enjoying New Zealand’s landscape and casual lifestyle, TJ thrives on the attitude of resourceful local DIYers, especially in remote areas where things need to be fixed or modified rather than just simply replaced.

“I didn’t come to New Zealand because it was pretty, I came because of aviator Dick [Richard] Pearse, Burt Munro, Britten motorcycles and people like Glenn Martin who invented the jetpack.”

The Slammer started its life in response to the tenacious bamboo growth that TJ was dealing with as a landscaper on the West Coast American state of Washington. Bamboo is a rapidly growing plant that has long been a challenge for workers tasked with removing the root systems, which require powerful directed force, often without the associated vibration of powered tools. Bamboo can crack concrete foundations, strangle electrical conduit and break up drains.

Having successfully tackled bamboo, the Slammer since then has evolved into a multi-purpose tool, not only used by landscapers but employed on building sites, fencing projects and lifestyle blocks.

Hand tools

TJ has a strong philosophy about the value of effective hand tools worked well.

“Few can fault an efficient hand tool. It’s manpower working accurately and quickly. A lot of those tools now have been replaced by the buzz of a two-stroke, high-torque whine of an electric motor, or the gentle rumble of the diesel powering the incredible strength of hydraulics.”

He says it can be hard to always have the electricity, petrol, or cash for power tools, so someone could appreciate something in the ute, boat, or backpack that’s not powered but works well.

“It’s better to have a simple tool rather than running to the hire centre all the time, spending a lot of money and using fossil fuels. Gives people work too.”

The Slammer is based on old, cast-iron mining tools known as “jack picks” and on modified landscaping shovels. These had lengths of pipe that slid down the tool shaft to drive the blade into hard, rocky earth and through stubborn root systems.

Changes

The tool went through evolutionary changes as problems were solved through almost eight years of development work with local fitter and welder Garry Templeton of Templeton & Sons in Albert Town (see PANEL, “Engineering history”). Early models had an issue with cracking occurring in the connection between the high-tensile steel main shaft and the bisalloy blade. After several attempts to use a plug weld, similar to a thick cotter pin, to hold the two together, it was finally decided to slot the blade into a thicker shaft than had been previously used. Not only was it cheaper, but the result was a much stronger unit, enabling the tool to be used as a large crowbar without concern. Older models were then replaced, and the Series 8 model is now ready to take on the bony ground of Central Otago and beyond.

One of the main benefits of its design is that the user can stand front-on to it and remain in an upright stance as they ram the weighted high-tensile rod downwards. There is no twisting, and it is much easier on the body than ramming a shovel into hard ground or slashing at root systems in the ground.

There is virtually no back strain, and as a result, the best feedback often comes from retired people as they work their lifestyle blocks. They can dig out broom, plant trees, and perform a number of literally backbreaking tasks that would previously require a mattock, crowbar or a powered posthole digger.

“My Dad is 72 now and two of his favourite things are planting trees and splitting firewood – which he can do with the Slammer,” says TJ.

West Coast

TJ – he has been referred to by the initials of his first two names Timothy James, since he was a child – first came to New Zealand more than a decade ago, travelling around the country and working for his board in rural areas. He said he lent his van to other “WOOFers” (the acronym for travellers who volunteer for work through World Wide Opportunities on Organic Farms) so he could bicycle through the countryside and meet the locals. He was drawn to the West Coast and the Cascade River south of Jackson’s Bay (it has the same name as the mountain range in the Pacific Northwest where he hails from, and a similar rainforest and climate).

He spent quite some time in the area, trapping possums and whitebaiting as well as working on farms in Central Otago doing work that ranged from shooting feral cats to general farm labouring. He embraced the West Coast lifestyle and would always return there after visits to other parts of the country, once travelling down there on a motorbike with a bathtub as a sidecar to hold his possessions.

“I often think I was born 100 years too late,” he laughs, referring to the West Coast as his “happy place.”

Bamboo

A keen skier back in the States, TJ originally started landscaping to support his sport at resorts like Jackson Hole in Wyoming. But after tearing a ligament in his knee, he gave up his teenage dream of appearing in ski movies and turned to developing his own business, Bamboo Solutions.

His first-ever bamboo removal job was at the age of 17, which he undertook for a bet. The business grew as the bamboo he removed could be propagated and used a few months later for screening and other landscaping.

He had heard about the skiing in the South Island from Americans who had been here, arrived and in 1999, pointed his motorbike towards Treble Cone in Wanaka.

After seeing the waterfalls and terrain of the Matukituki Valley from the access road to the ski field, he decided Wanaka would be an ideal base for his adventures. He ended up buying a caravan for $500 (which is still in his driveway) and settling in the area.

After returning home to wind up his business, he settled here and continued developing the tool which he’d started tinkering with back in the US. He had little initial success with a number of engineering firms to make the Slammer. About eight years ago, he met Garry Templeton and, using a sketch on the back of a Speight’s carton, the two started a business relationship that has thrived.

TJ says Garry Templeton’s passion for creating a high-quality product was evident from the first time he was presented with a broken earlier version of the Slammer. “If it broke, he took it personally,” he says, and, only after several years of trial and error, the Mark 8 is a tool they are both happy with.

TJ speaks very highly of the ethics and approach at Templeton & Sons, the engineering firm that turned out to be in his backyard. He believes a crucial aspect of the firm’s approach is their tradition of designing and fabricating tools and farm machinery that is made to last. He says in the past, there was little, if any, back-up if machinery failed out in the field, and the ensuing downtime could threaten the harvest.

Hard sell

Like many good ideas, however, getting to production is only part of the success story.

TJ admits it is a hard sell to get people in Wanaka to change their work habits and try a new tool. Despite glowing recommendations from landscapers, builders, the Treble Cone ski resort and numerous landowners, he finds the Slammer sells better out of town. Momentum is building with approximately 700 sold so far, and he is a regular face on the rural sales Fieldays circuit.

While the Slammer may be a basic, almost medieval tool in appearance, TJ’s one-man-band marketing approach is definitely at the cutting edge of technology. He has an easy-to-use website at theslammertool.com with an original, entertaining video clip introducing “Slammerman” who demonstrates the tool’s various uses from work to recreation – including anything from 4WD retrieval to fishing and safety tips.

The site has a page that celebrates “mandraulics” and highlights the latest successful “slamtastic” project – stump removal, stone breaking, chipping up old floor tiles – that the Slammer has been called in to perform.

Enthusiasm

It’s been a long road for TJ Irvin and his wife Rachel, whose support extends to being featured in the new brochure using a Slammer while pregnant. Now with 18-month-old Theo on the scene, the family finds that money is extremely tight, and any income goes right back into the business.

Meanwhile, anyone meeting him will be aware of a seemingly endless amount of enthusiasm for his pet project and life in general. “TJ can be the king of tangents,” laughs Rachel after witnessing the wide variety of subjects he held forth on in our interview. “But he has an incredible brain.”

Topics leapt from business ethics and local industry, the West Coast lifestyle, the philosophy of manual work and the environmental benefits of hand tools, then onto another project he’s working on using mirrors to heat water in car radiators to create steam for energy. Cheap disposable tools from China? Don’t get him started.

He has supported himself through the years doing a huge range of odd jobs, often with the Slammer in hand, which he has documented to show the tool’s versatility

But he says he could not be doing this on his own. “It takes the strength of a really good partner.”

And he has had a lot of support from people who believe in the project. “The people around give you strength.”

Garry Templeton, while slightly less animated, believed strongly in the potential of the Slammer when he first saw one of the prototypes, and his opinion has been backed up by users – including his wife who grabbed it the other day and was impressed by its utility.

“It’s the best bloody thing since sliced bread.”

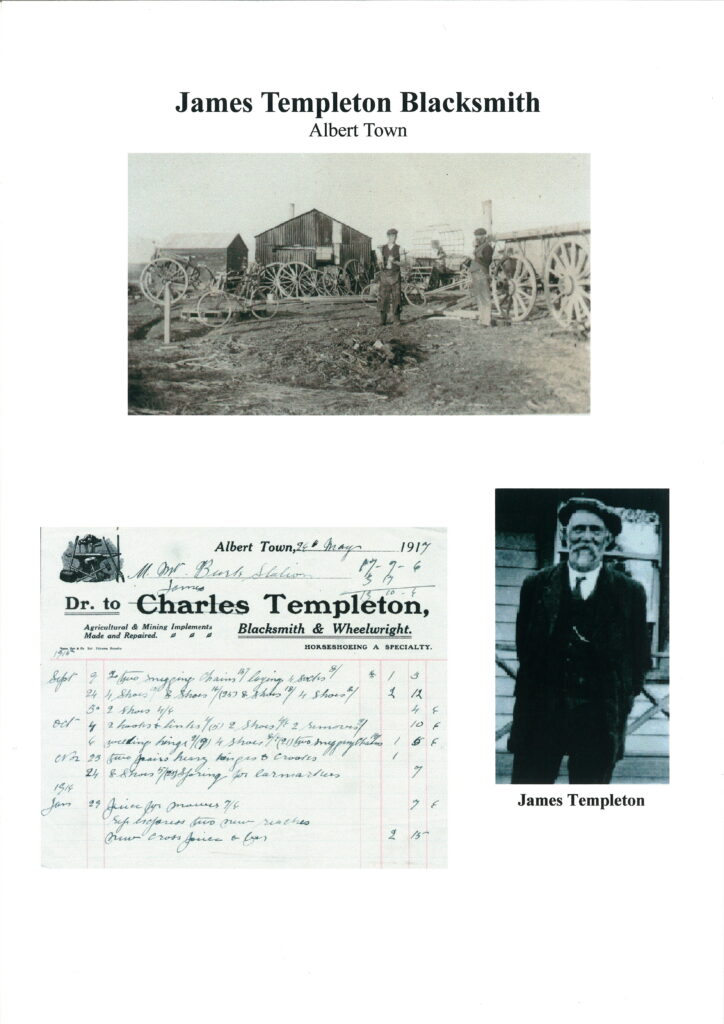

Templeton & Sons Engineering Ltd – a history

The work ledger of Templeton & Sons Engineering Ltd reflects the history and evolution of industry and farming in Central Otago over the past century. In that time, the firm’s work has changed literally from dealing with horse carts and ploughshares to mechanical farm machinery and mining equipment. More recently, they employ precision engineering for architects, ski area construction requirements and much more specific design for compliance.

The current owner, Garry Templeton, was apprenticed into the family business as a fitter and welder 35 years ago. He is the fourth generation of an unbroken line of Templeton men to have the craft of metalwork handed down to him in the business.

Garry’s great-grandfather, James Templeton, set up business as a “blacksmith and wheelwright” shop in 1896. In April 1906, James shifted from his Wanaka lakeshore workshop – now the site of the tourist information centre – to the present company site on the banks of the Clutha River in Albert Town. As well as a blacksmith, James was the local “punt man,” ferrying people and goods back and forth across the river in a barge before the bridge and road were built linking the area to Haast and the West Coast.

One of the biggest changes in the Wanaka area’s growth for Garry is the fact that there are now a lot of people he doesn’t know. But, he says, “we still get the guys coming in with a hand-drawn sketch of what they want and we still make it work for them.”

Despite the installation of modern plasma cutters, oxyacetylene torches, presses and lathes, reminders of the industry and skills of another era are retained with piles of horseshoes, anvils, blacksmith tongs and enough dusty iron debris to satisfy the nostalgia of any old metalworker. The old forge retained at the centre of the workshop was fired up for the firm’s 100th anniversary in 2006, but this is a rare occurrence as gas and electricity have been used for the past few decades to heat and form steel.

The Slammer is one of the standing orders the workshop has – they created a run of 24 for TJ to take the recent Fieldays at Mystery Creek in the Waikato. Workshop staff and TJ, as the tool’s developer, have collaborated closely to get the tool to the standard they are both happy with.

“We’ve had headaches all right,” says Garry of the trial and error of some of their earlier prototypes. But he always believed in the tool’s practical applications from the first time he saw one. He says the tool has huge potential and they are getting excellent feedback from clients who have made the shift away from the more conventional mattock, shovel and crowbar for manual work.