A Kiwi in London uses his sheddie skills to create an audio man cave and build the ultimate speaker clone

By Dean Johnston

Photographs: Dean Johnston

I’ve always been interested in music and hi-fi and always thought the best scenario for serious listening would be a dedicated sound-proof music room where you could listen at all hours of the night at any volume without disturbing anyone. A man cave for want of a better term.

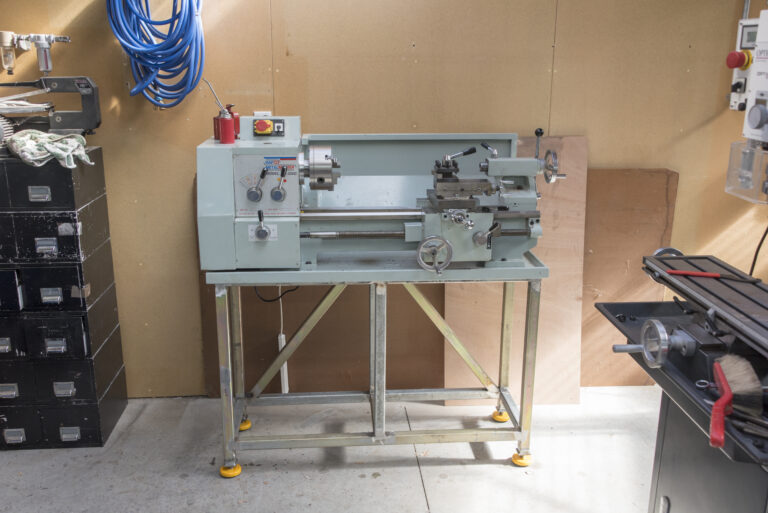

I was lucky enough to buy a house with a large detached garage which the previous owner had built for his automotive engineering pursuits. At 13m x 5m, this is unusually large for where I live in London and would never get planning permission nowadays, of course.

The garage is a single-storey prefab of concrete construction with concrete corrugated roof panels, which was common in the 70s. For many years, the garage was just a storage facility and rubbish dump until I finally got around to transforming it into a music room and art studio for my wife (always good to have a guise for spending large amounts of time on a DIY project – I’m doing this all for you, my darling).

Big speakers

This project got me thinking about a large-scale DIY speaker build that was somewhere between a club system and high-end audio to fill the studio with pumping sounds.

I have always been a fan of the radical design of the Focal Utopia range but have not had the budget to match it. Happily, I came across an advert for a set of Focal AudioM drive units (15″ WX woofer, 6.5″ WM mid, TD5 tweeter) and struck upon the idea of building a Utopia clone with these drivers, giving some lineage to the original.

I did consider doing my own design, but something is rewarding about building a clone speaker as it fulfils a desire for a recognised high-end product at a fraction of the cost, and most of the design work is already done for you if you follow the same dimensions, baffle, port, etc.

The speakers are a clone of the third generation Utopias, which have many innovations such as separate boxes for each drive unit to avoid any distortion across channels, with each box angled towards the listener to ensure correct timing, which they call “Focus Time”.

“There is something rewarding about building a clone speaker as it fulfills a desire for a recognised high-end product at a fraction of the cost”

Less hassle

I have done one smaller DIY speaker project before and found the traditional crossover design frustrating as it is fixed once soldered and difficult to alter but has so much bearing on the sound. I had recently attended a hi-fi enthusiast show where a DIY speaker with digital active crossover was on display. This got me thinking that a self-built speaker would be a lot less hassle and more fun without the passive crossover.

The digital active crossover made by MiniDSP processes all the sound channels in software, much like a surround-sound system. It is highly flexible and makes the complex speaker build possible for a novice with no electronics experience. One downside is that you need an amplifier for each output channel, which means six amplifiers, which produces an active speaker set-up.

The prototype

I decided to build a prototype to help me understand the angles and taper of the cabinets while testing the drive units. They did actually sound decent before launching into a full-scale build. I used the original Utopia speaker dimensions and photos to guide the design, combined with a lot of guesswork. The rear taper and angles were a real challenge, as I couldn’t find that information anywhere on the web.

I built a simple frame to support the baffles and give me an idea of the various angles to achieve the “Focus Time” idea of all drive units directed to the listener’s ear. I used the laser on my skill saw to line up the angles against a point on the wall at ear height.

“I decided to build a prototype to help me understand the angles and taper of the cabinets while testing the drive units did actually sound decent”

Initial Testing

With the prototypes roughly screwed together, I set up all the components and connected the speaker cable to each drive unit using crocodile clips to some cheap amps I bought on eBay. I really didn’t know what I was doing, and it took me a long time to get any kind of coherent sound. By slowly adjusting the crossover frequencies and outputs to each component and the volumes on each amp, I managed to get a full bandwidth sound and proved that the drive units are all in good working order. This was a welcome result at the right time as even building the prototypes had been a lot of heavy, dusty work and I was starting to question what I was doing.

Cabinet build

Before I started on the build proper I visited a well-known London hi-fi store to have a look at the Utopias. This was very helpful to get a feel for the overall size and the various curves of the cabinet. They are very impressive in scale and design.

I bought a belt sander, which is very good for shaping wood quickly, and found this was the best way to make the curved baffles and flared openings for the drivers, which was easier than expected. For the curved sidewall I used 6mm MDF bent around a baton and glued and screwed into place as I don’t trust glue alone to hold the pressure on the curved panel over time. For most of the construction I have used the glue-and-screw method into batons to join panels together. I looked at jointing methods but the angled side walls makes it tricky to get a flush finish to both sides of the join. I then used flexible wood filler to complete any gaps in the cabinet to avoid leakage.

Pay off

The build process on the first speaker was slow, with a lot of thought required on how to achieve the curves on the baffles and how to join the boxes together. Each box took around 12 hours or more work to complete over about four months of late evenings.

I made all the baffles for both speakers in one go, doing all the cut outs while the router was set up for that cut, and machined from a single piece of wood where possible so that the curved baffles were consistent. I then cut to length. This sped up the construction of the second speaker massively, which was done in about two weeks.

Building such large, elaborate boxes for the tweeters did seem over the top, but once the whole speaker is put together, it makes sense, and the long hours are forgiven.

Tricky angle

The joining blocks between each box were tricky to construct as they needed to be angled on both sides like a V somewhere near 20° and solid all the way round. When shaving down these blocks, I ended up with a lot of waste material, but it was the only way to get solid angled blocks. The angle of the boxes to the listener, or the focus time, will be fixed but can be adjusted using spacers if needed. The bolts and wingnuts give a way to break down the cabinets without too much trouble if needed for transport, but it took some thinking through as the cabinets will be closed before painting, so I had to put all the bolts in place first and hold them in place with nuts.

Finally, I had the cabinets completed and sanded, ready for painting. There was a lot of work to get a consistent shape and depth to the overlapped edges between the top panels and side panels. I did some simple testing with the woofer in place to ensure bass response was effective with no vibration from the cabinet.

“The prototypes had been a lot of heavy, dusty work and I was starting to question what I was doing”

Painting

To simplify the painting job, I opted for one colour all over the boxes and a matt black finish to the plinths and tweeter units for contrast. I used a 2K auto paint, primer, base coat and clear coat finish; all applied using an HVLP spray system I had used previously for the house.

The 2K paint is nasty stuff, and although I used proper breathing apparatus, it was still a very toxic job. I’m lucky my shed is far away from other houses. Next time, I would use a water-based primer and base coat and a 2K clear coat, but I took what the local paint shop gave me.

I had a few runs in the clear coat, but I managed to sand these out with fine-grit paper, and I’m very pleased with the end result. I could have spent more time perfecting the finish by wet sanding and respraying the clear coat to get a mirror finish, but I just couldn’t justify the time. I had considered taking them to be professionally painted, but I’m pleased I could do the whole thing myself and avoided having to transport the heavy units.

Putting it all together

After joining all the boxes together and running the internal speaker cable through holes from top to bottom, I used crimped terminal connectors to connect the drivers, which I found much easier than soldering.

I then crimped the internal speaker cable directly onto the external cable so the cable was fixed to the speaker but easy enough to change as the rear panel of the bass unit was removable.

I used hex bolts on all the drive units, which gives them a great finish. The large hex bolts on the tweeter unit’s baffle are for looks only, to mimic the original. I added some absorption foam inside the units on the sides and rear to soak up reflections and some internal bracing to support the woofer from underneath, as they are very heavy units.

“I don’t trust glue alone to hold the pressure on the curved panel over time”

First Listening

I set up the digital crossover frequencies to the drive unit spec sheet, and the initial sound was good enough for an impromptu Friday night disco as word got out around the neighbourhood. The sound output is pretty massive and easily fills the garage with bass levels to rival a nightclub. The bass extension is pretty phenomenal and will easily rattle the windows and vibrate the ceiling but is easy to tame with the volume control on the amps.

“I had considered taking it to a local paint shop but I’m pleased I could do the whole thing myself”

Man cave conversion

Once I had completed the speakers and cleaned up the huge amount of MDF dust, I moved on to the garage and the man cave conversion itself.

I lined all the internal walls with 18mm hardwood ply over 15mm sound-proof wallboard attached to a 3×2 timber frame with 70mm glass fibre insulation infill.

On the ceiling, I used 50mm foam insulation panels with a bonded 6mm ply finish, which was easy to fix to the purloins and lightweight.

On the external walls, I used treated 2×2 timber in a vertical pattern attached to battens to get a modern, cabin-style look. This layered approach gives good sound damping and reasonable heat retention.

The soundproofing, together with the fact the garage is at least 15m away from any neighbouring houses, means that virtually no bass can be heard, which is ideal for late-night listening and parties.

I’m proud of the speakers and very pleased with the end result. Visitors are quite literally blown away by the scale and sound of the speakers. The finish on the cabinets is nothing like that of the actual Utopias and puts into perspective the workmanship and man hours that go into building a high-end speaker like that. But still, it gives me a little taste of the Focal Utopia experience – a poor man’s Utopia. I’m good with that.