Lloyd Knowles does his sawmilling using tiny, hand-made blades

By Sue Allison

Photographs: Juliet Nicholas

The smell of marcocarpa and scream of saws greets visitors to a family-run sawmill up a valley behind Motueka where Lloyd Knowles specialises in making one-off timber products, often with intricate profiles, for do-it-yourself builders, renovators, and furniture-makers.

“We make a whole range of stuff from weatherboards to architraves, as well as replica mouldings using different profiles. We just make a pattern to fit whatever they want. Negative detail is the flash term,” says Lloyd, who runs the business with his wife, Diane. Most requests for bespoke work come from Golden Bay and Motueka. “A lot of people around here are doing their own building now, especially baches.”

Lloyd’s father ran a small mill on the property in the 1960s before turning to tobacco farming. “He made the mill up from parts, starting with derelict steam-driven machines hitched to a tractor and adding electric motors. The gorse grew up through it and you couldn’t even see the sawmill when I got there.”

Lloyd was working as a joiner in Motueka in the 1970s before hanging up his hammer to resurrect the mill and build a house. “I made all the windows and cupboards before I left, then just had to build a house to put them in and hope they fitted,” says the droll sawmiller, who claims he built the house, where he and Diane raised their family and their daughter now lives, with a skill saw.

“A lot of people around here are doing their own building now, especially baches”

Fruit boxes

In 1985, he transformed an old lean-to barn below the house into an operational mill and from small beginnings grew it into a boutique business that now employs a full-time staff member as well as the couple and their son.

“We started out making pallets for the kiwifruit industry,” says Lloyd. “Next they wanted trays. Little boxes out of thin bits of wood. One year I made 44,000 of them. We got two or three years out of that before they went to cardboard.”

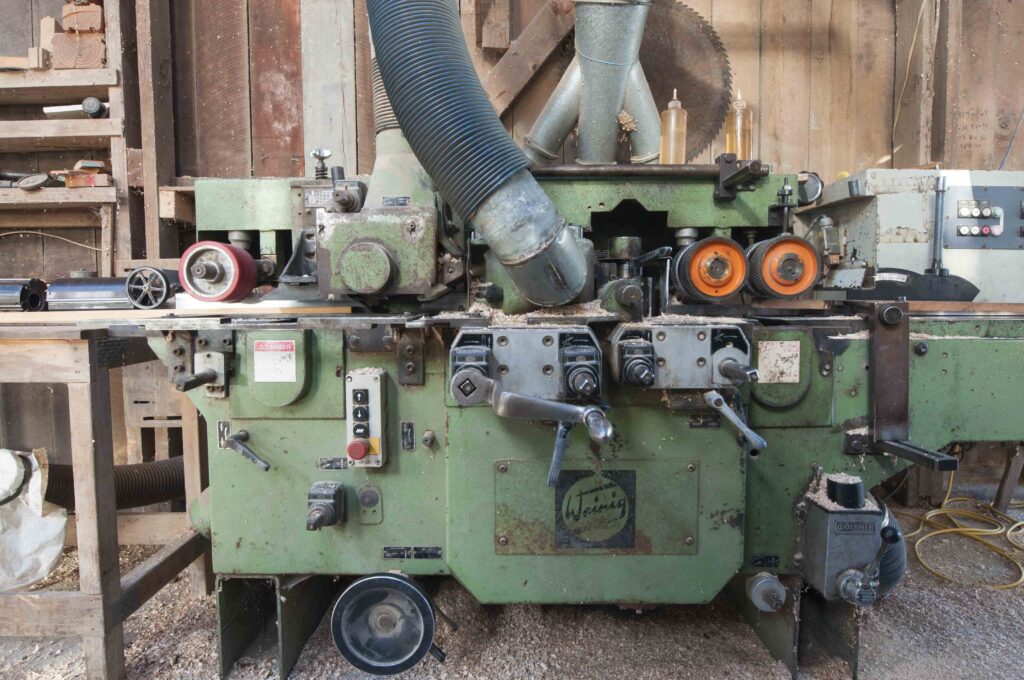

Garden trellis was their next bread-and-butter line. “We made miles and miles of that, then started doing tongue-and-groove with an old four-sider. It’s a museum piece now,” he says. “Once we got this high-speed machine, we were away.” The Weinig four-sider sawmilling moulder acts like a giant router, with moulding blades attached to cylinders to shape the profiles a bit at a time. Lloyd cuts and files all the blades, or knife steels, to shape by hand.

No job is too small but Lloyd admits to losing a bit of sleep over fiddly jobs. “It can be a challenge. It takes a lot of time to set it all up and make a few bits of timber,” he says. “People restoring old houses will bring in a sample and ask for so many this long and so many that long. We’ve just done four 27cm pieces of detail for a tile edging.”

“It can be a challenge. It takes a lot of time to set it all up and make a few bits of timber”

Hand-built belt sander

They keep a stock of dry timber stacked and ready to use, including macrocarpa, poplar, pine, and lawson cypress as well as native beech and rimu. Most of it is plantation-grown or windfall, though a lot of people bring in wood from their own properties to be machined. Dryness can be an issue with privately supplied wood. “People have often stored it in sheds under plastic so it isn’t dry enough. It’s got to have air,” says Lloyd, who sometimes stacks wood in the office to speed-dry timber. “It’s my kiln,” he says.

The Knowles have built up an array of heavy-duty equipment over the years, much of it adapted from the early milling days. There’s nothing shiny in this shed and barely a shred of plastic in sight. The oldest saw still has its original Cadillac gearbox. Lloyd reckons his hand-built belt sander, a “relic” in leather and wood, does just as good a job and is more reliable than its modern counterparts.

“Most of it came out of the ark,” says Lloyd. “The whole site really needs to be turned into a museum.”

History

Before the invention of the sawmill, boards were split (rived) and planed or sawn by two men with a two-handled whipsaw. ‘Saddleblocks’ or ‘dogs’ were used to hold the log in position over a sawpit. It was exhausting work, especially for the top sawyer who had to balance on the log, guide the saw and didn’t have the pitman’s advantage of gravity.

Early sawmills adapted the whipsaw to mechanical power, generally driven by a waterwheel. A connecting rod known as a pitman arm (the origin of a term now widely used) converted the circular motion of the wheel to the back-and-forth motion of the saw blade.

Circular saw blades were invented around the late 17th century. Gangsaws, which had several parallel blades so a log could be reduced to boards in one step, soon followed. Circular saw blades were prone to damage by overheating or dirty logs, giving rise to a new technician, the sawfiler, whose job was to set and sharpen teeth.

Mills became highly mechanised with the advent of steam power in the 19th century, and further so with electricity. Most aspects of saw-milling are now computerised.

From logs to lumber

Technology may have changed, but the milling process is much the same:

A sawyer uses a headrig (or headsaw) to break the log into cants (partially processed logs with at least one cut surface). The irregular surfaces are trimmed, or edged, leaving four-sided lumber and the ends squared to length. Lumber must be dried before use to remove the natural moisture. It can be stacked to dry naturally, a process that can take several years, or kiln-dried. Once dry, the timber is planed to smooth the surface and give a uniform width and thickness and any embellishments or profiles can be worked.