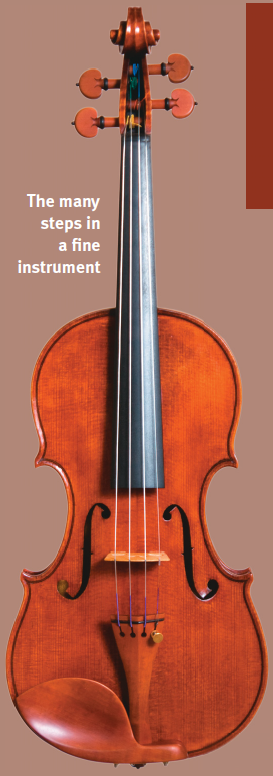

The many steps in making a fine instrument

By Richard Panting

History

In the last 200 years, the violins of two great names, Antonio Stradivari (1644-1737) and his near-contemporary Guarneri “del Jesu” (1698-1744), have served as wonderful models of beauty, style and functionality. They were part of a relatively new tradition in the small Italian town, Cremona.

The earliest known violin, by the patriarch Andrea Amati, dates from 1564 and Stradivari is thought to have been an apprentice and maker in the Amati family workshop until he set up his own business, possibly around 1670. Violins by Guarneri “del Jesu” have power and projection as well as beauty and I have mostly modelled my instruments on these.

Yehudi Menuhin played Stradivari and Guarneri violins.

Glue

Traditional, hot hide glue has been used by musical instrument-makers for centuries and is the only good glue for instrument-making. If done right, a joint is more than strong enough. It is water-soluble and so joints can be dismantled without damaging the wood if repairs are necessary, usually impossible with synthetic glues. Hide glue also makes for fine glue lines. I only mix and prepare enough for the job at hand, as it tends to go mouldy after a few days.

A small jar heated in a water-bath or gluepot to 65-70 ºC is good. The hot water in the container is also useful for glue clean-up.

Making a violin

When I decided to make a violin to take to a conference in America, I chose a beautiful example by Guarneri “del Gesu”—the “King” violin made in 1735—as a model.

Given the significance of the violins by the great makers, there is a respected tradition of making copies or instruments modelled on their work. I was quite happy for The Shed magazine to follow its progress but as there are books written in great detail about violin-making, this magazine article can only be a summary of what I did and some of the problems I encountered.

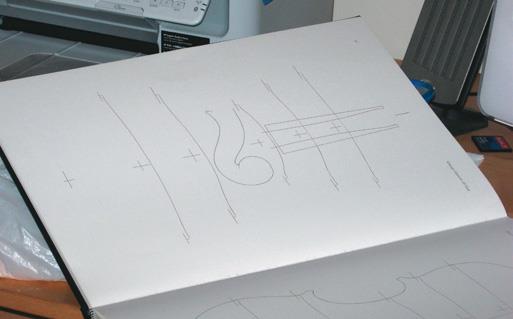

The project is done over two issues of the magazine. I used plans, technical drawings and the full-size photographs available for this violin to make my own patterns. I also wanted this violin to have wood with that special beauty that captures the attention of any onlooker but it had to be acoustically fine as well. For this, the wood has to be cut correctly, free of any major blemishes and be resonant with a clear bell-like “ring.” I have a reasonably large stack of seasoned wood and spent many hours looking, tapping and wondering about a good choice (SEE NEXT SECTION – Wood).

Full-size book plan of Guarneri cross-arches.

Moisten ribs before bending them.

Ribs shaped around electric bending iron.

Ribs formed around mould.

Wood

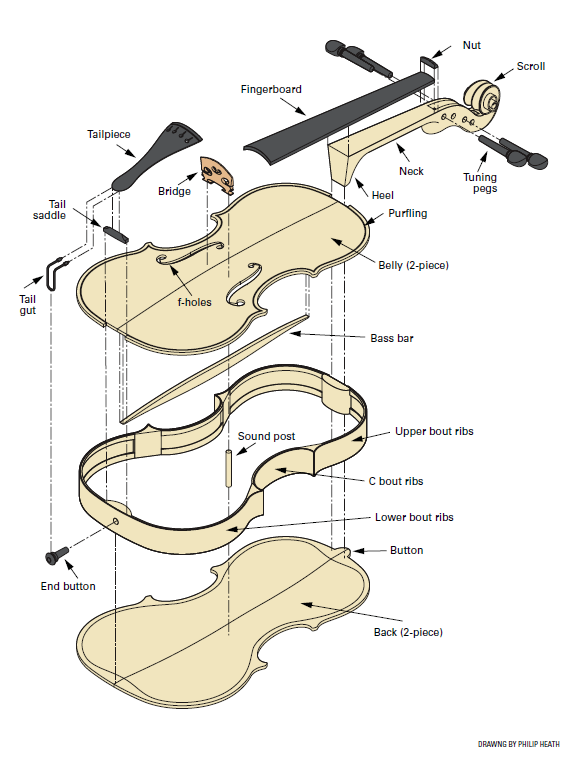

The correct wood is crucial to the success of a violin. Traditionally, standard timbers used are spruce for the belly (top), maple for the back, ribs (sides), neck and scroll and ebony for the fingerboard, nut and saddle.

The fittings—pegs tailpiece, chin rest, end button—usually matched, can be boxwood, ebony or rosewood among others. The decorative border (purfling) is a sandwich of three strips of purfling, black, white, black, traditionally black stained pear-wood with willow or poplar, or so sometimes unstained pear-wood in the centre.

Traditional woods (from left) ebony, maple, spruce.

I have been lucky to source my wood from a traditional German merchant who has 60-year-old-plus flitches of spruce and maple in his attic. The more mature the wood the better and the denser the wood the greater its response to sound.

It has been said that decades of 17th-century hard winters—a mini-Ice Age produced outstanding woods for the Guarneri and Stradivari families to use in the early 1700s (described in the tree ring science journal Dendrochronologia).

The spruce top or belly as a soundboard is light but very strong longitudinally, has very regular grain-width and is resonant, essential qualities for vibrating freely and quickly.

Maple for the back has a distinctive figure of stripes or “flame” horizontal to the grain, often called tigerstripe or fiddleback through its regular use in violins. Maple has been used for centuries in instrument-making, is of medium hardness and weight, heavier than spruce and provides structural stability to the “box.” Ebony is a hard, dense wood with good wear characteristics to withstand the repeated pressure of fingers and strings.

Specialist suppliers, largely in Europe and the USA, can provide spruce and maple in wedge-shaped billets of appropriate length.

Maple fiddleback stripes.

These are book-matched (further cut or split lengthwise in half and joined in the centre) to provide a wide enough piece. One-piece backs are also common and often very striking in appearance. The block for the scroll and neck and the strips for the ribs should ideally match the back.

Mould

The outline for the mould for the violin body is taken from the full-size back outline in the technical drawing I reduced this to allow for the thickness of the ribs and the overhang of the plates. I use a full-height, two-part mould. It lets me easily trim the ribs to their finished height; separated it supports the rib garland when I bend and fit the linings.

The wood for the top and back now has to be jointed and flattened on one face. The flat surface is the reference for using contour gauges, thickness calipers and layout. A planer/ thicknesser makes life easier here. I had to be careful with the maple as it is easy to get tear-out with this highly figured wood. The opposite surface has a shallow triangular profile which accommodates the arched surface.

The mould with ribs glued on.

Back with “button” area on top bout.

Ribs

I bent the ribs before cutting the front and back plates out. I bent them around the mould and glued them to the shaped blocks which are temporarily glued to cut-outs in the mould. The sequence was: centre ribs first, trimmed to the mould surface, then all exterior blocks shaped, then the upper and lower ribs bent and glued. The rib stock needs to be planed, scraped and sanded to a thickness of 1 mm for the centre ribs, 1.2 mm elsewhere.

As the “flames” of the wood create sections of end grain along the length of the strips, they are flexible but weak when bent, so the ribs are steam-bent around an electric bending iron with a flexible backing strip for support. The wood needs to be only lightly moistened. It’s helpful to practise on some spare rib wood (a few snapped pieces are almost inevitable). Set the iron thermostat correctly, you don’t want to scorch the wood.

With the ribs glued to the blocks, I cut the corners back and filed them to create an intersection about 1 mm wide, square to the upper/ lower ribs respectively.

The holding jig placed on turntable.

Ribs clamped with C bout block.

Outline

Now the finished ribs on the mould can be placed and clamped on the centre line of the flattened plates, to draw the actual outline of the violin. I drew one outline to the exact outline of the ribs (this is for easy reference when gluing the body together) and the second with an offset of 3 mm to give the exact outline of the plate.

I left the four corners a little long to allow for final shaping. A bandsaw with a 6 mm blade is good for cutting the plates out and sanding drums of several diameters in the drill press help to make a smooth bump-free outline. Don’t forget when marking out the back to allow for the “button” at the centre of the top bout. As an extra re-minder, I find it’s best to make the two small cuts with the bandsaw first.

Caliper draws contours.

Home-made gauge sets drill depth.

Plate shaping

The plans show the different height and curves of the long and traverse arches of both belly and back. To shape belly and back, I start with a rotary planer in the drill press to plane the top of the plates to my planned height with an extra 0.5-1 mm to allow for final adjustments.

From the plan, I make “female” arching templates of thin wood or MDF and lay them over the appropriate points on the centre line of the instrument. This is a quick and convenient way to check progress. For carving and hollowing out the plates, a holding device is really useful. Mine is on a turntable and made of plywood, relieved to approximate the convex curves of the violin. It can hold the plate upside or downwards and I can rotate the work to any position quickly and easily. The force required to carve maple is considerable, so the jig needs to be quite solid.

Drill holes help with wood removal.

Working across maple back, held by solid jig.

Back

I start with the back which is harder work than the soft spruce of the belly; slower work gives you the “feel” of the wood. Sharp gouges, plane blades and scrapers are essential, and are safer than pushing too hard with a blunt tool. When cutting maple work across the plate: the wood cuts cleanly and doesn’t tend to tear out. After the heavy cutting, toothed blades in the smaller thumb planes let you cut with and against the grain relatively easily. Both plates need to be reduced to the same edge thickness around the perimeter before carving starts. I leave the middle bout area at 4.5 mm, the corners at 5 mm and the upper and lower bouts at a little over 4 mm. This border is about 8 mm wide around the upper and lower bouts and 6 mm in the middle bout area.

I have a rotary planer that mounts in my drill press and makes a good job. This consistent flat area makes it easier to create the finished edge and cut the purfling channel with a consistent depth. The different heights are blended into each other with file and sandpaper.

“Swiss cheese” effect.

Purfling

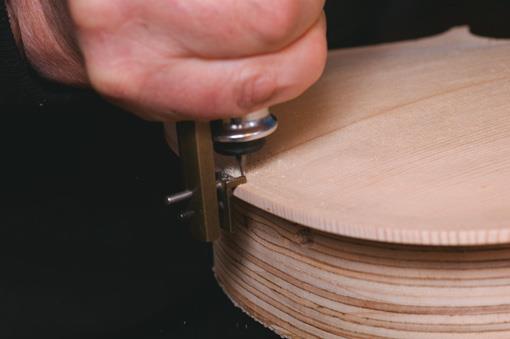

After I have removed enough waste to have established the rough shape of the arching, I like to cut the purfling channel and fit and glue the purfling.

The total purfling width for violin is between 1.2-1.4 mm and it is usually set in about 4 mm from the edge. Purfling in all varieties is sold ready-made and it is good to match (in width at least) the purfling in the violin you are using as a model.

In the belly there are eventual cut-outs at the top and bottom centres for the neck and tail saddle respectively, so you can use six separate pieces of purfling. The back perimeter however has a continuous line of purfling and here I like to use four pieces—two for the centre bouts and one each longer piece for the upper and lower bouts. This means that the only joins are at the corner mitres.

The purfling strips are somewhat brittle and although only 2 mm high, benefit from bending the corners to approximate shape with the rib-bending iron. Usually no water is needed as the strips are so thin. But be careful to use the minimum amount of heat as the strips can delaminate.

Before cutting the corner mitres, check that the purfling is a comfortable fit in the channel as the glue will swell the wood and make the purfling impossible to fit. Not a good feeling after painstaking work cutting the mitres. I usually start with the bottom right corner, using the same knife that I used for cutting the channels in the corners and work around in a clock-wise direction.

Cutting a well-fitting mitre needs practice. Fortunately purfling isn’t expensive so don’t worry about using strips for practice. Sometimes I cut a perfect mitre only to find that the other end of the purfling piece is just a fraction too short. Bugger. A slight concavity in the cut helps the two pieces to push together nicely.

Purfling tips

Purfling channels traditionally done by hand were marked with a scribing tool, the lines deepened with a fine, sharp knife and the waste removed with a mini “pick.”

Today many makers use mini-routers to cut most waste and finish the corners in the traditional way. I’ve done both and routing produces excellent results in a fraction of the time (without blisters).

But power tools are unforgiving and you have to double-check your settings—height of cutter and edge off-set. Practise a lot on scrap wood before advancing to your prized (and expensive) plates. The traditional purfling marker (set exactly to the same channel width and offset) can continue the channel-marking into the corners. Stradivari is admired for the skill and elegance of his corners—the point bisects the corner width in the ratio 2/3:1/3 with the slightly elongated, outer black layer creating a “bee sting.” Guarneri’s purfling channels are often roughly cut, the corners blunt and the purfling often forced into the channel. But his strong character and obvious stylistic surety have a great appeal.

Mini-router cuts purfling channel.

Dry-fitting purfling.

Mitred marked in corner.

Thumb planes ( note toothed blade).

Gluing

With the purfling dry-fitted, I put Tite-bond liquid hide glue in a large syringe with a blunt needle. I wouldn’t use it for gluing the violin but it is perfect for this application—it doesn’t gel and is used cold so you have plenty of time to align the parts perfectly.

I start by lifting out one C bout purfling and 60 mm of each of the other pieces. Use the syringe to fill the channel then assemble one mitre accurately, pressing it into the corner. Work the C bout piece back to the other mitre and re-fit that also. I find magnifying glasses or a headset a great aid for aligning the mitre.

Lift out the remaining C bout and the loose end of the long pieces, fill the channel with glue and fit the corners first. Work the rest of the strips back into the channel. I then go around the whole inlay several times with a small smooth hammer head, or the purfling pick, pushing the purfling into the bottom of the channel.

When it is sitting properly, I wipe off the excess glue and finish by brushing around the whole perimeter with hot water. This swells the wood and tight-ens the inlaid purfling nicely. Leave to dry overnight.

Mitred purfling for corner.

Purfling dry-fitted in corner.

Shaping

Now I continue with the external shaping of the back and belly. I like to establish the long arch first and then work sideways to create the cross-arching profiles. By now most of the cutting will be being done with thumb planes, and scrapers are used to smooth the bumps. A useful aid to keeping the arching symmetrical is the contour caliper which I set to draw a line 20-30 mm in from the edge around the plate.

When I have finished drawing about 8 lines, about 20 mm in from each other, I have what looks like a contour map. Lopsidedness or irregularities are easily seen then corrected with planes and scrapers.

When the arching is close to finished, I make the initial edge scoop. First, with a pencil compass I draw a line 2 mm in around the edge of each plate. Using a 15-18 mm gouge I then reduce the thickness of the plate inside this line, i.e. directly over the purfling, to an even 3.5 mm.

The final thickness here will be around 3.2 mm so I take care to make this as consistent as possible. Using an oval scraper, blend this channel into the main arching.

The complete edge will be rounded over and finished during assembly of the body.

When I’m happy with the outside arching of the back, I use sandpaper on a small cork sanding block about 50 x 30 mm with one rounded end and slightly convex bottom, to finally clean up the surface.

Raking shadow-lighting from an angle-poise lamp shows all the imperfections of the surface you have to attend to.

Hide glue syringed into channel.

Purfling pick pushes inlay down.

The back

The back thicknesses follow a carefully worked-out pattern with the thickest part a little higher than centre. Oval zones around this point decrease the thickness from about 4.5 mm to about 2.4 mm in the upper “lung” area, and about 2.6 mm in the lower. A layout of pencil lines is transferred to the flat surface of the back.

There is a lot of waste wood to be removed and I use a “stop-drilling” procedure to allow me to quickly and accurately get down to the nominal thickness for this hollowing-out process.

I mark the thickness of each zone clearly on the wood, set up the drill press with a raised pin in the table centre and a 3-4 mm drill in the chuck. I use the depth stop on the drill to drill holes about 20 mm apart in each zone. Be careful to tilt the plate as necessary to drill the holes perpendicular to the outside of the plate, i.e. the carved surface. I also allow an extra 0.5 mm for safety.

With the plate firmly secured on the holding jig, I start hollowing out with larger spoon gouges, working across the plate. The “Swiss cheese” appearance of the surface is my reference to the final depth and as I approach the bottom of the drill pits I can start to use the thumb planes again, the toothed blades in these making the job easier. Once a uniform appearance is reached, with a pattern of small pits evenly across the surface, I switch to convex scrapers to smooth the surface. It is important to keep clear of the perimeter line drawn 20 mm in from the edge. This gives a margin of safety for the gluing surface around the edge of the plate.

I also use the thickness caliper from here to check the thickness of the plate. These calipers read to 0.1 mm and I try hard to get my graduated surface to within 0.1 mm consistency. Patience is the name of the game here. Now it’s time to be aware of the stiffness/ flexibility and weight of the plate which will start to have a bell-like ring when held on a nodal point and sharply tapped.

The weight and stiffness—or flexibility—are factors which directly affect the responsiveness of the violin. Lighter is mostly better and flexibility too, but I am careful not to compromise the strength of the wood. The final thickness of the back has to be balanced with that of the belly in a process of “tuning” the plates to each other.

Purfling finished.

Draw f-holes and drill eyes.

The belly

The belly has a simpler thickness schematic. To hollow it out, as with the back I draw and mark all the areas on the flat surface before starting. One very obvious point of difference with the belly is the cut-outs, called the f-holes, due to their similarity to the old-fashioned letter f.

These are placed on a line drawn across the outside of the plate, 195 mm from the top edge at the centre and at right angles to the centre line. I make one f-hole pattern taken from the plans and use it to draw both f-holes on the outside (carved) surface. The nominal width is shown as 42 mm between the upper “eyes” of the fs but this differs a little according to different makers’ models. The outside edges of the lower eyes of the f-holes are placed according to the plan. Masking tape is useful to hold the pattern while I draw the f-holes on the plates.

I now drill the eyes of the f-holes from the outside (carved surface), perpendicular to the surface. There are sets of hand-cutters available for this but an appropriately sized spur drill bit (at least 0.5 mm smaller than the marked hole diameter) is quite OK.

Have a bit of scrap as a backing when drilling, to minimize any splintering. Then I locate the pattern on the inside and re-draw the f-hole outline. This helps in drawing the zones for the stop-drilling process.

Cutting f-holes.

Fluting

An important stylistic feature of Cremonese-styled f-holes is the “fluting” or slight channel that runs from the bottom of the wing to just past the nicks in the f. I use a shallow 18 mm gouge to remove a small oval of wood, about 0.75 mm deep and starting just inside the bottom curve of the f-hole to about 10 mm past the nicks.

Then I blend this depression into the general arching with a scraper. It is important to do this now, as it’s easily forgotten and when done too late, makes the wings of the fs too thin.

Refining graduations of plate.

Plate drilling

Although I have described the back and belly process separately, in practice I find it quicker, with less chance of mistakes, if I do both plates side by side. So, for example, the stop-drilling can happen all in one session (hard on the knees, at least with my drill press set-up). So the plate drilling is now done on the belly and I can start the hollowing out.

Spruce is so quick to carve after maple. This is fun but you need to be even more aware and controlled in your carving as it’s easy to gouge too deep or exuberantly. Spruce, unlike maple is easy to carve with the grain, so my rotating holding jig is very useful here, allowing the optimum cutting position to be easily found.

Cutting f-holes

When a large portion of the waste is removed and the inside surface semi-smooth I start cutting the f-holes. Some makers use a fine fretsaw to begin; I use two or three different drills to chain-drill out the bulk of the waste. The precise shaping is done with two fine-bladed knives, with a left and right bevel. I alternate these so I am always using the flat of the blade against the edge when I cut with the grain.

The cut is perpendicular to the outside surface, not undercut.

The points of the wings are fragile so a spot of superglue helps to preserve them during cutting.

With the f-holes completed, I refine the graduations of the plates using the fine-set thumb planes and sharp scrapers followed with sanding block and paper. If the stop-drilling is accurate I can usually go to the bottom of the drill pits but I always check frequently with the thickness caliper. By now the plate will feel quite flexible when gently twisted from top to bottom. The top and bottom lung areas can be flexed separately so I have a feeling of their relative stiffness. Also I check the “ring” of the plate by holding it on the various node lines.

SEE PART TWO: Finishing the violin.