The November/December 2019 Issue 87 of The Shed, has a real electronics feel about it but there is also a lot here to keep all sheddies informed and well-skilled up.

Our cover story is about the goal of a Christchurch boat builder, architect, designer, sailor, Quentin Roake, to find a way to build waka in large numbers. He wants to recreate the appearance and characteristics of traditional craft in a modern version that is portable, durable, and economical to manufacture. Quentin has made it his mission to put Maori waka back on the water by marrying traditional knowledge with today’s technology. His journey is a very uplifting tale.

Staying in Christchurch, two sheddies combine to build an electric skateboard that can hit speeds of 45k plus! Gavin Bath and Mark Beckett walk us through the step by step build of this pavement rocket ship.

We have Part Three in our How to weld series, this issue it’s how to TIG weld before we head off to the shed of a record breaking electric motorcycle builders, Eva Hakansson and Bill Dube. This couples’ need for speed has seen them build the record breaking KillaCycle which reached a speed of nearly 390 kph and now a new and faster beast is being constructed, the Green Envy.

This issue sees the commencement of a new series of brewing tips from Bryan Livingston of Brewers Coop fame, Part One is getting to know your hops and some great brewing tips to enhance your own brewing skills.

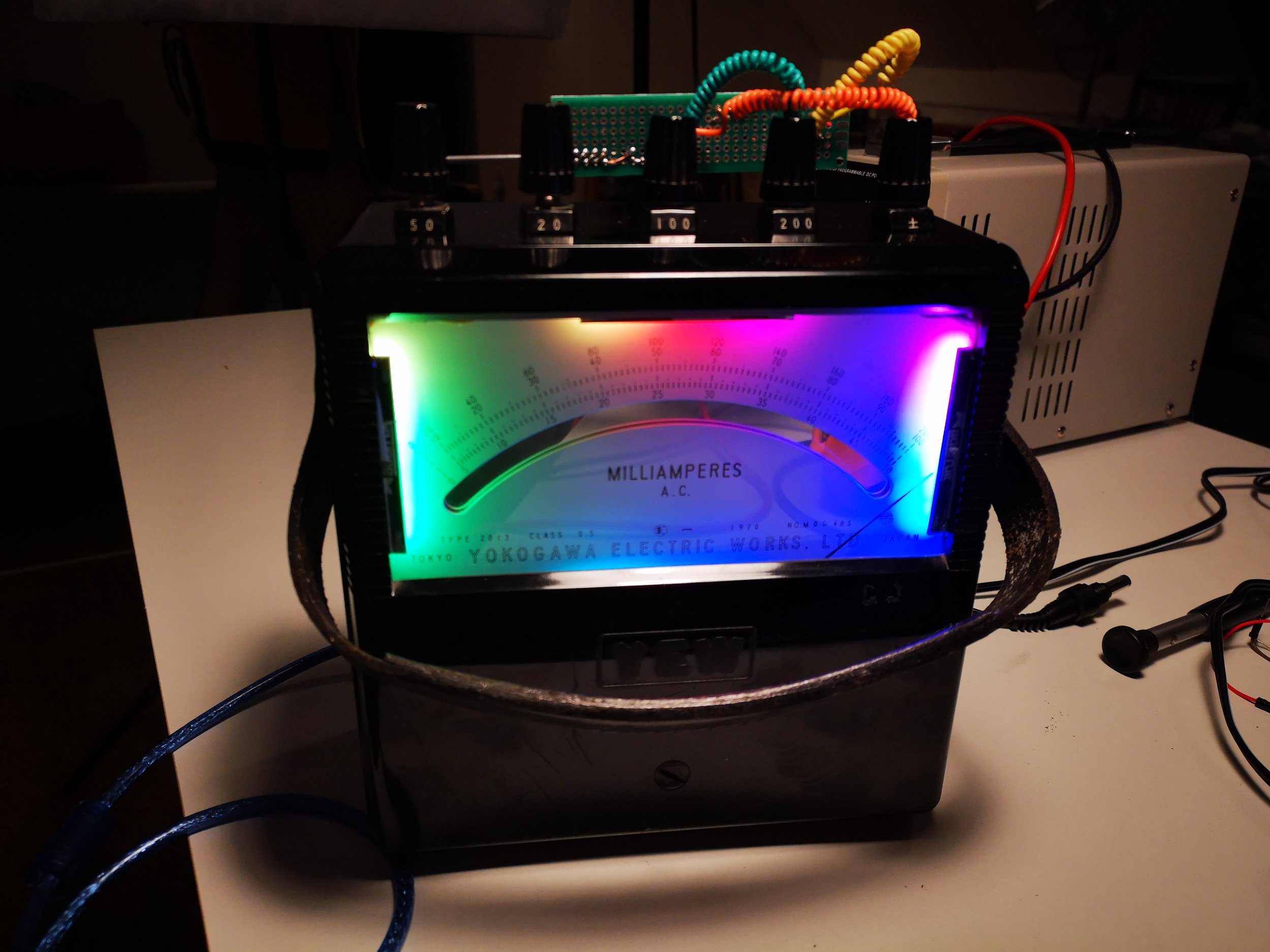

Coen Smit shows us how to make the humble coffee table something of a talking piece in your home and Enrico Miglino starts out on his new adventures by upcycling vintage tech items. He first completely restores them then changes or adds to their range of functions. Part One is upcycling a mid 20th century Milliampere Meter.

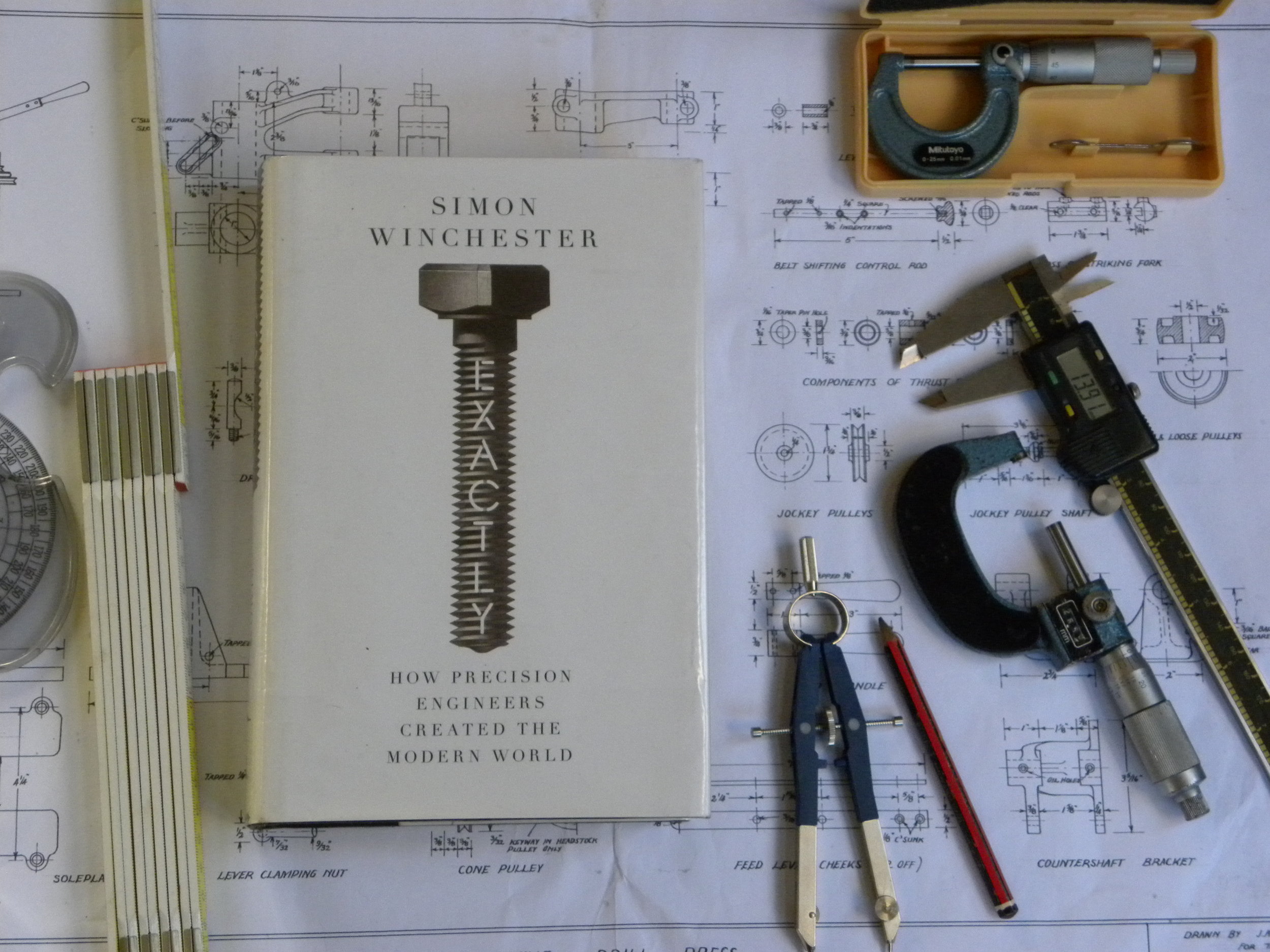

Ritchie Wilson reviews the excellent book EXACTLY – How Precision Engineers Created the Modern World by Simon Winchester before heading to the local workshop of electronic collector and engineer, Tim Pattrick.

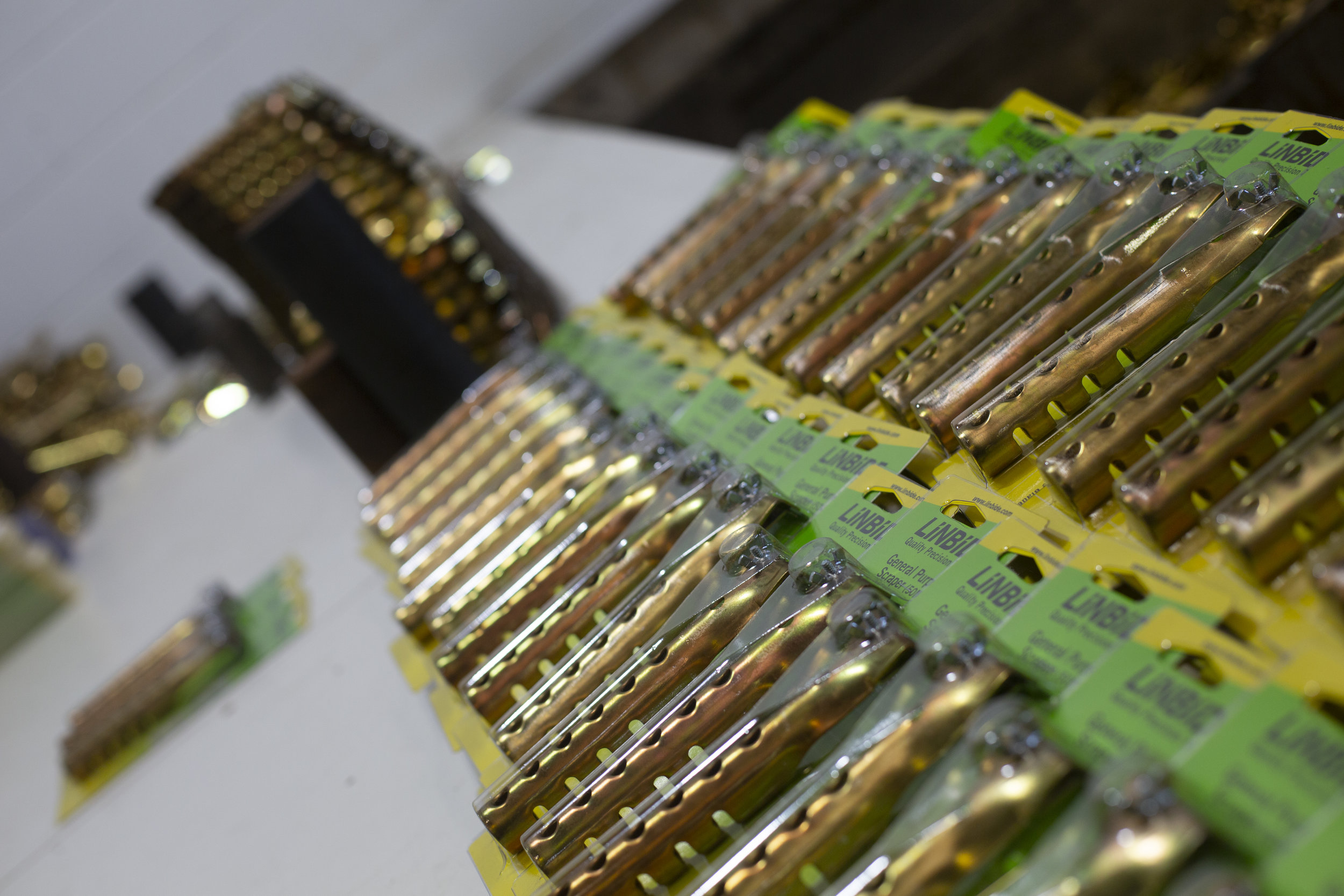

Murray Grimwood shares his glasshouse building knowledge in this issue’s Off the grid column and then Ian Parkes heads out to the industrial area of Penrose in Auckland to meet Grant and David Lindsay the owners of Kiwi tool making company Linbide. Many of us will have used their great wee tungsten scraper but they also make saw blades and more.

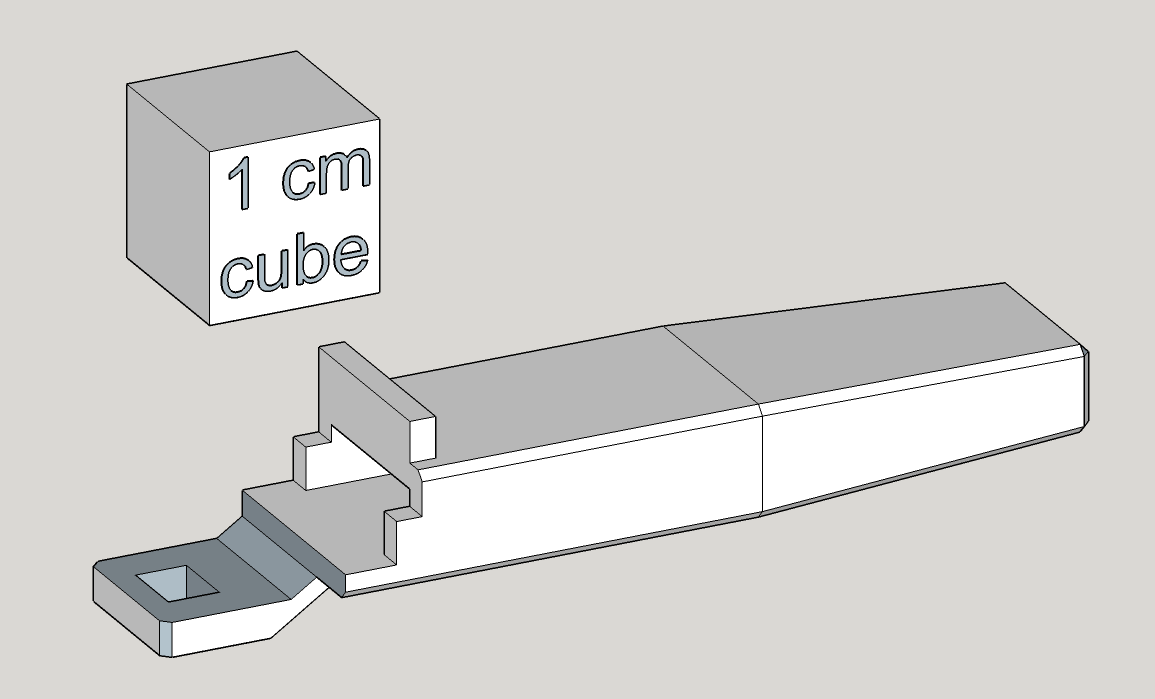

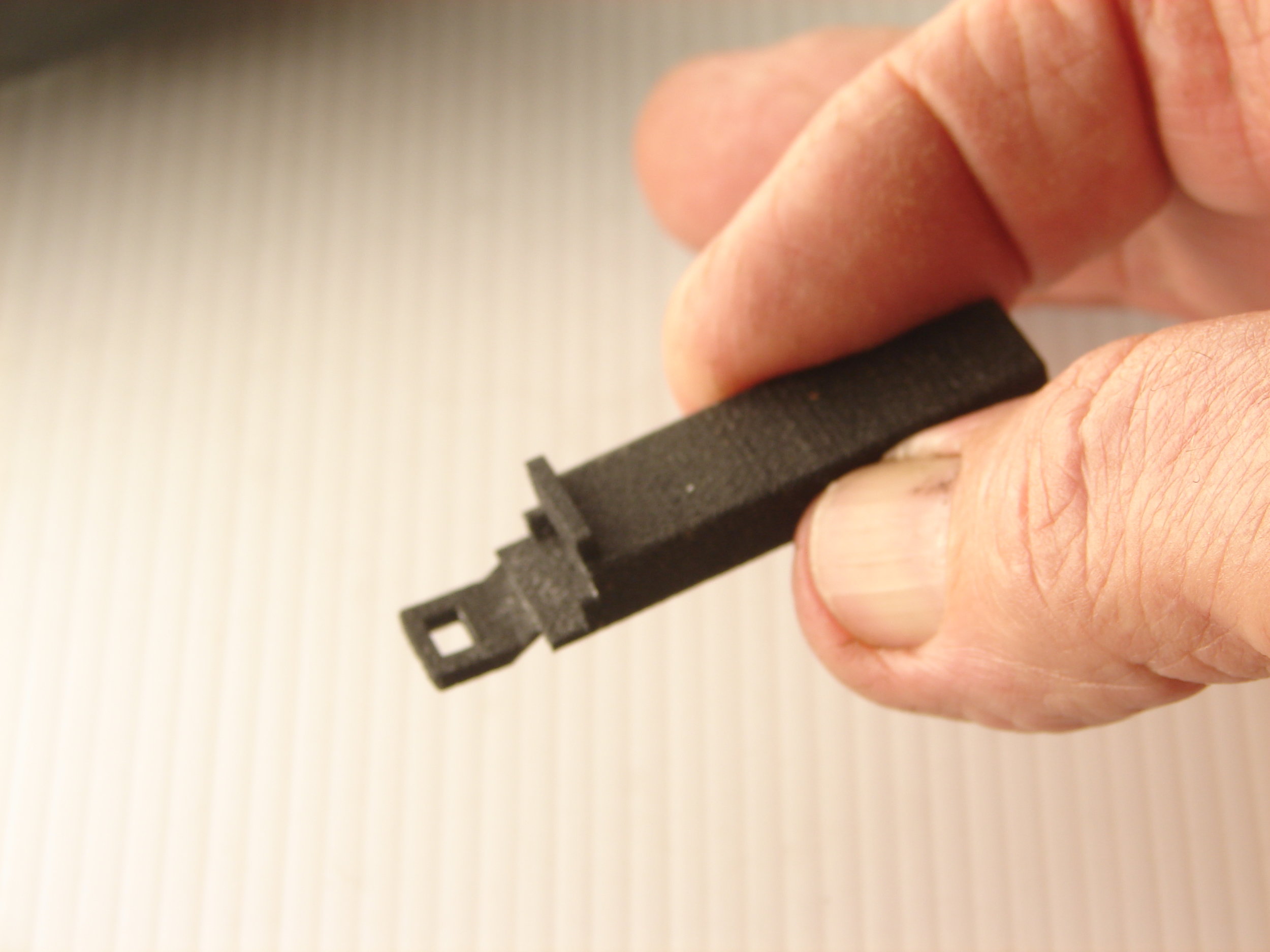

Mark Beckett has been very busy this issue and gets making some Christmas gifts on his trusty CNC router, Hugh McCulloch uses 3D printing to repair his trusty mobile landline phone and Bob Hulme gets making some fireworks just cos… it’s that time of year.

We begin to close this issue with a visit to a very talented multi-tasker, Anna Bates. Anna lives out in the West Auckland bush where she creates unique pieces in her newly restored railway-hut shed in her back garden. Prepare here for shed envy.

As usual, Jude Woodside closes the magazine and shares with us his success and the limitations of his newly installed solar power panels that generate 3-phase power, on a good day, for his workshop shed.

To purchase a copy or to subscribe head to https://magstore.nz/